Excertos do catálogo

I laxP.y M34 is a-i epoxy system, specifically developed for ow temperature cuing <y lame structura components, particularly in industrial markets, HsjiRy M34 is a sel;-extin;;.!Snng îysten. p'ov din:;; excel ont f-ro-ros ;tan* proper c-s. ard meeting the German and French rail qualifications DIN 5510, S3-SR2-ST2 and NF F 16-101 (M2, F1). HexPly1 M34 piepieg is beai for mí nu'act uri ifl sand-.vici structures, p-ov-di'vi e\ce en: ad'iasior :o -VG 'oam cores. HexPly* M34 exhibits a good shell life at Room Temperature tor a low temperature curing system. ■ 10 days sheit lite at RT ■ Self adhesive on foam (PVC) and on honeycomb ■ Low pressure moulding capability 0.8-3 bar (12-43 Psi) ■ Good tcxbi :. e ■ : i:y o1 prepregs ■ Suitable for thick laminates - low exotherm

Abrir o catálogo na página 1

HexPly® M34 Resin Matrix Properties Rheology Gel Time Viscosity/poise Gel Time (minutes) 10 3 300 250 10 2 200 10 1 120 ˚C (250 ˚F) 90 ˚C (195 ˚F) 6 min 50 min 150 100 10 0 50 0 -1 10 20 40 60 80 100 120 60 70 Temperature ˚C 80 90 100 110 120 Temperature ˚C Cured Matrix Properties cured at 75°C (167°F) - 8H Test Glass transition temperature Cured resin density Flexural Values 80ºC (176ºF) 1.26 g/cm3 Str = 120 MPa (17.4 Ksi) Mod = 3.8 GPa (551 Ksi) Method DMA Prepreg Curing Conditions The standard cure cycle is 8 hours at 75ºC (167ºF), at a pressure between 0.8 and 3 bar. The following...

Abrir o catálogo na página 2

75°C (167°F) curing epoxy matrix Typical Mechanical Properties on HexPly® M34 prepregs Main references (Others available) E-glass Balanced fabric 600 g/m2 E-glass Balanced fabric 300 g/m2 HS 12k carbon Balanced fabric 600 g/m2 0° Tensile strength MPa (Ksi) 400 (58) 600 (87) 900 (130) 0° Tensile modulus GPa (Msi) 20 (2.9) 21 (3) 65 (9.4) 0° Flexure strength MPa (Ksi) 670 (97) 700 (101) 950 (137) 0° Flexure modulus GPa (Msi) 20 (2.9) 20 (2.9) 65 (9.4) / 540 (78) 600 (87) 53 (7.7) 50 (7.2) 70 (10) 50 55 60 TEST 0° Compression strength MPa (Ksi) 0° Short beam strength MPa (Ksi) Fibre volume...

Abrir o catálogo na página 3

HexPly® M34 Product Data Prepreg Storage Life n n Shelf Life @ 23 + 2 °C (73 °F) 10 days Guaranteed Shelf Life @ -18 °C (0 °F) 12 months Precautions for Use The usual precautions when handling uncured synthetic resins and fibrous materials should be observed, and a Safety Data Sheet is available for this product. The use of clean, disposable, inert gloves provides protection for the operator and avoids contamination of material and components. Important All information is believed to be accurate but is given without acceptance of liability. Users should make their own assessment of the...

Abrir o catálogo na página 4Todos os catálogos e folhetos Hexcel Composites

-

Rail

5 Páginas

-

Wind_Turbine_Blades

12 Páginas

-

Automotive Product Focus

4 Páginas

-

HexWeb® EC Engineered Core Brochure

8 Páginas

-

HiTape® Reinforcements Brochure

4 Páginas

-

HexWeb® Honeycomb Selector Guide

4 Páginas

-

A_World_of_Composite_Technologies

15 Páginas

-

Winter_Sports_Brochure

6 Páginas

Catálogos arquivados

-

HexTow® Chopped Fiber

2 Páginas

-

HexMC®-i / C / 2000 / M81

2 Páginas

-

HexMC®-i / C / 2000 / M77

2 Páginas

-

Redux ® 100 series

4 Páginas

-

HexPly ® M78.1

4 Páginas

-

A1 & A10

4 Páginas

-

HexMC

6 Páginas

-

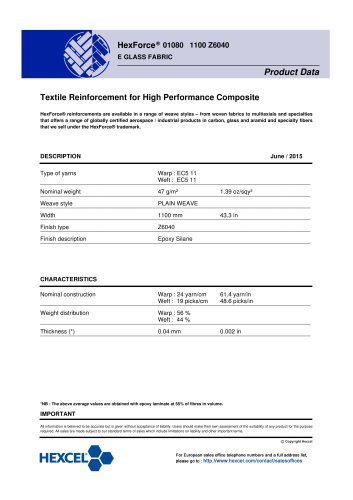

HexForce

12 Páginas

-

MARKET BROCHURES-Rail

5 Páginas

-

HexPly® M81

4 Páginas

-

HexPly® M77

3 Páginas

-

HexPly® M10R

4 Páginas

-

HexPly® M47

4 Páginas

-

HexPly® M49

4 Páginas

-

HexForce_Technical_Fabrics_Handbook

116 Páginas

-

HexWeb_Acousti-Cap

4 Páginas

-

HexPly M9M10

4 Páginas

-

CarbonFiber_SelectorGuide_us

4 Páginas

-

HexForce? Fiber Glass Fabric

1 Páginas

-

HexForce? Aramid Fabric

1 Páginas

-

HexForce Hybrid Composite Fabrics

1 Páginas

-

Redux epoxy film adhesive

4 Páginas

-

Honeycomb

40 Páginas