Catalog excerpts

SELF-PRIMING PUMP FEATURES Permanent magnet type, fully enclosed, stainless steel shaft. Jabsco Neoprene compound 1/2" Internal Pipe Threads 1" External Hose Barb Adapter for 3/4" External Garden Hose Thread included Motor meets USCG Electrical Standards 183.410 and ISO 8846 MARINE for IGNITION PROTECTION on gasoline powered vessels. ! Explosion hazard. Do not operate with rivets removed from motor case. Explosion resulting in personal injury, death or property damage can occur. Case openings must be sealed to avoid explosion and maintain ignition protected rating. OPERATION Flexible impeller pumps must NOT be run dry, as the pumped liquid is the lubricant for the impeller. Observe the outlet and shut off pump as soon as liquid stops flowing. An automatic level switch is convenient to control the pump. The pump cannot run against a closed outlet such as encountered when using a garden hose type shut-off nozzle. Pressure for normal operation should not exceed 20 feet of head (8.7 psi). Temperature of pumped liquid may be in the range of 45° - 180°F (7° - 82°C). APPLICATION Use for bilge pumping, livewell circulation, washdown and general pumping requirements. If bilge water contains significant amount of oil, the standard impeller should be replaced with impeller No. 6303-0003, which is an oil-resistant nitrile material. Pump has a dry prime suction lift of about 4 feet (1.2m) and a lift to 20 feet (6m) when primed. BE SURE SUCTION LINES ARE AIRTIGHT. Light housing gets hot during Motor runs hot—about 180° is a normal operation. Do not contact during temperature. Prolongedtouch during or immediately after operation. operation may cause a burn. Burns can res

Open the catalog to page 1

INSTALLATION The pump must be mounted in a dry location - the motor is not waterproof and must not be submerged. SELECTION OF A COOL, VENTILATED location will generally extend pump motor life. The unit can be mounted in any desired position. It is best to mount so that water dripping from a loose port connection will not wet the motor. The pump head may be rotated 180° on the motor to change direction of flow. PLUMBING CONNECTIONS Pump ports have external 1" hose barb and internal 1/2" pipe threads. Also provided are two male port adapters to allow the attachment of 3/4" female garden...

Open the catalog to page 2

MAINTENANCE Check wires and connections to be sure corrosion is not adding additional resistance to the motor circuit and causing a low voltage condition at the motor. Low voltage can inhibit motor from starting and cause fuse to blow. Full voltage should be available to prevent motor damage. NOTICE: If pump is idle for extended periods, the impeller may stick to the pump body, preventing motor rotation and causing blown fuses. To correct, remove end cover and impeller, clean body and impeller, then lubricate with water or small amounts of grease before assembly. If pump is to be in...

Open the catalog to page 3

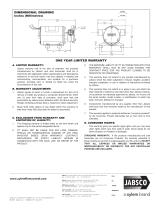

ONE YEAR LIMITED WARRANTY A. LIMITED WARRANTY: Jabsco warrants that at the time of shipment, the products manufactured by Jabsco and sold hereunder shall be in conformity with applicable written specifications and descriptions referred to or set forth herein, free from defects in material and workmanship, merchantable, and suitable for a particular purpose, provided such is implied by State law under the circumstances of this sale. 1. Jabsco agrees to repair or furnish a replacement for, but not to remove or install, any product or component thereof which, within one (1) year from date of...

Open the catalog to page 4All Xylem catalogs and brochures

-

23680 Technical Data Sheet

2 Pages

-

23610 Technical Datasheet

2 Pages

-

18670 Technical Datasheet

4 Pages

-

18220 Promotional Datasheet

2 Pages

-

General_Industrial_Catalo

24 Pages

-

Jabsco Marine Toilets

16 Pages

-

Oil_Change_Diesel

6 Pages

-

Flexible Impeller Pumps

54 Pages

-

Marine Product Catalog

7 Pages

-

Additional Information 11

4 Pages

-

Chemical Resistance Guide 10

6 Pages

-

Specialty Products 09

6 Pages

-

Sliding Vane Pumps 08

2 Pages

-

Oscillating Pumps 07

2 Pages

-

Rotary Lobe Pumps 06

3 Pages

-

Industrial Pumps Catalogue

94 Pages

-

FLOJET Beverage Run Rise Charts

10 Pages

-

Washdown Pumps

2 Pages

-

Water Pressure Systems

10 Pages

-

Toilet Systems

14 Pages

-

Livewell/Baitwell Pumps

6 Pages

-

Bilge Pumping Systems

24 Pages

-

Aerogen Wind Generator

3 Pages

-

Speciality Products

5 Pages

-

Sliding Vane Pumps

5 Pages

-

Oscillating Pumps

2 Pages

-

Rotary Lobe Pumps

3 Pages

-

Hand Pumps

2 Pages

-

Gear Pumps

2 Pages

-

Diaphragm Pumps

15 Pages

-

Centrifugal Pumps

19 Pages

-

MODEL 34754-0000

2 Pages

-

MODEL 34744-0000

2 Pages

-

4125 SERIES

4 Pages

-

4105 series

4 Pages

-

2760-SERIES

2 Pages

-

Exploded View

2 Pages

-

Impeller Replacement

10 Pages

-

Searchlights

8 Pages

-

Ventilation Blowers

4 Pages

-

General Purpose Pumps

8 Pages

-

Oil Change & Diesel

6 Pages

-

Washdown Pumps

2 Pages

-

Water Pressure Systems

10 Pages

-

Livewell/Baitwell Pumps

6 Pages

-

Toilet Systems

12 Pages

Archived catalogs

-

Bilge Pumping Systems

26 Pages

-

Service Parts

80 Pages

-

Impeller Replacement

16 Pages

-

Searchlights

12 Pages

-

Oil Change & Diesel

10 Pages

-

FLOJET BevJet

12 Pages

-

General Purpose Pumps

14 Pages

-

OVERVIEW OF PARTS

2 Pages

-

59000_aqua_filta_promo

2 Pages

-

Type III MSD Waste

18 Pages

-

52600 Series

18 Pages

-

SELF-PRIMING

4 Pages

-

VENTED LOOP SOLENOID

1 Pages

-

233SL Dual Beam Searchlight

2 Pages

-

MINI ACCUMULATOR TANK

2 Pages

-

Par-Max Series

2 Pages

-

Jabsco

2 Pages

-

Marine Product Guide

24 Pages

-

Brochure

4 Pages