Catalog excerpts

THERMOPREG™ Fabrics Commingled Polypropylene Glass Fabrics PRODUCT DESCRIPTION Thermopreg™ Fabrics - Commingled Polypropylene Glass Fabrics are made of continuous commingled glass and polypropylene filaments. Consolidation is done by heating above melting temperature of PP matrix (180°C-230°C / 360°F-450°F) and applying a pressure (1-30 bars), before cooling step under pressure. Depending on parts to be produced, vacuum molding, diaphragm, or calendering process can be used. PRODUCT REFERENCE WR t – 0750 – PP 60 W - 00/01 – 152 Weaving pattern: Orientation: Rounded nominal weight Thermoplastic resin: Glass fiber ratio Color: Internal code Width WR (Woven Roving) t (balanced) / x (unbalanced) 0750 (g/m²) PP (%wt) B (black) / W (natural) 00/01 152 (cm) PRODUCT APPLICATION Thermopreg™ Fabrics are mainly used for the following applications: Automotive - Marine - Transportation - Sports & leisure – Renewable Energy - Building & Construction. FEATURES AND PRODUCT BENEFITS Ready to Use Product – The Thermoplastic Resin is inside Ease of Storage conditions Fast Processing Cycle Time High Mechanical Properties with Impact Resistance and Weight Saving COMPOSITE MECHANICAL CHARACTERISTICS (AFTER MOLDING) VALUES GIVEN IN WARP / WEFT DIRECTIONS OR AVERAGE OF BOTH DIRECTIONS FOR BALANCED PRODUCTS Strength MPa (psi x 103) Tensile Impact Un-notched Charpy Glass content Strength Flexural Woven balanced Mechanical property data was developed in accordance with standard ISO specifications Mechanical testing performed on 3mm thick molded samples Relative values shown are accurate to the best of our knowledge, but should not be used for design purposes since absolute values can be influenced by processing condition. More specific data are available upon request

Open the catalog to page 1

THERMOPREG™ Fabrics PP Glass Commingled Fabrics PRODUCT AVAILABILITY* Product Reference * Other Thermopreg™ Fabrics patterns and widths are available upon request and MOQ PACKAGING Each roll of Thermopreg™ Fabric is wrapped in a polyethylene bag and palletized STORAGE Thermopreg™ must be stored in its original packaging, away from humidity and at moderate temperature. The best conditions are: Humidity between 35% and 65%. If the product is stored at low temperature (below 15°C/60°F), it is advisable to condition it in the workshop, for at least 24 hours before use, to prevent condensation....

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

OPTISPRAY®

2 Pages

-

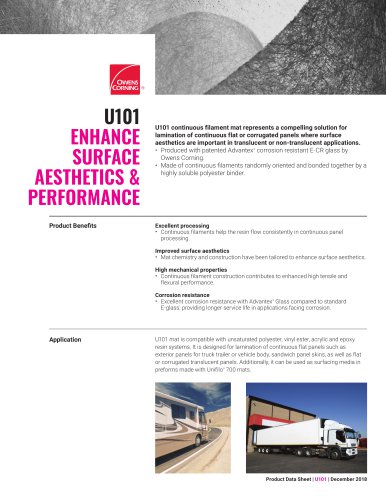

U101

2 Pages

-

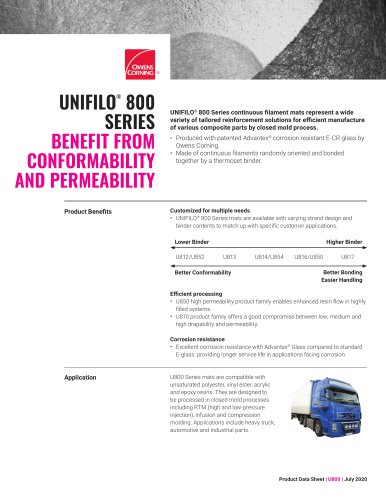

UNIFILO® 800

2 Pages

-

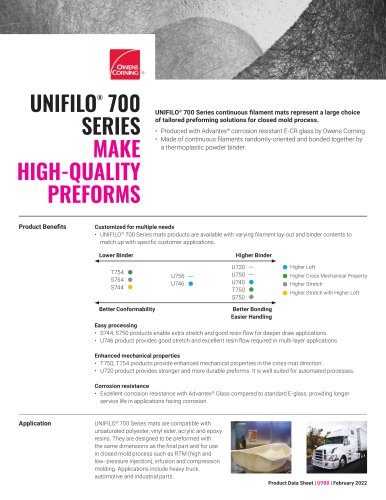

UNIFILO® 700

2 Pages

-

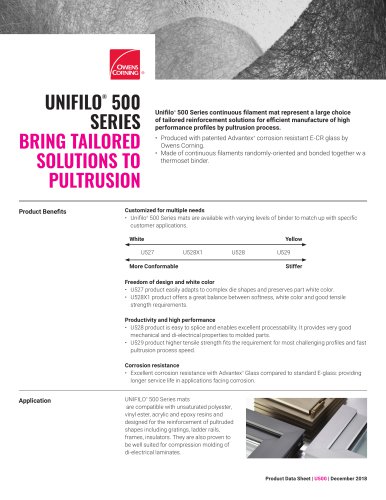

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

M723A

2 Pages

-

M705X1

2 Pages

-

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

FoodContact™

2 Pages

-

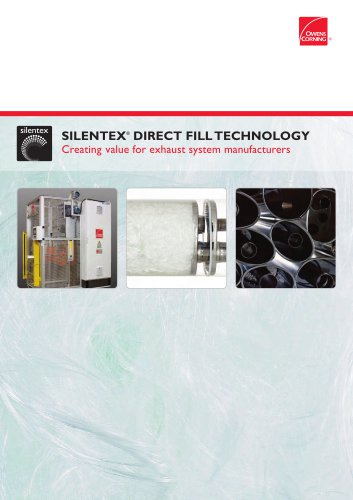

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

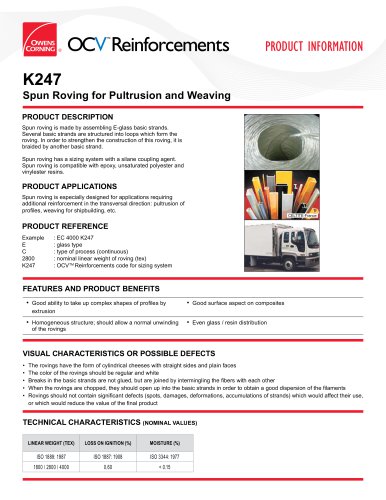

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

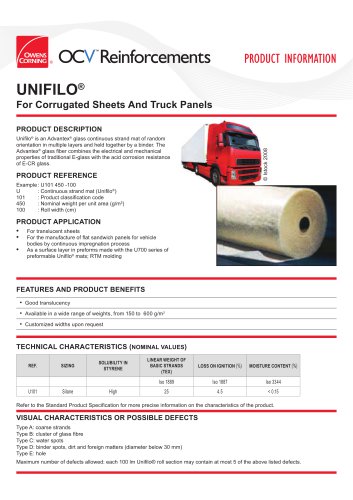

Unifilo® U101

2 Pages

-

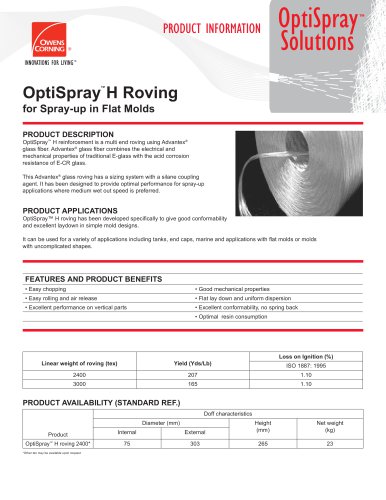

OptiSpray H Roving

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

Single_EndRovings_Range

2 Pages

-

SingleEnd_Roving_ST2070

2 Pages

-

SingleEnd_Roving_ST1048

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRov_973

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

GRC Spray Roving

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages