Catalog excerpts

ST 1048 Single End Roving Designed for Silentex® Noise Control Solutions The Silentex® noise control solution is a unique system that enables improved durability and acoustic performance while significantly reducing overall system cost. PRODUCT SOLUTIONS © JLSponga INNOVATIVE SOLUTIONS Advantex® continuous roving is an integral part of the Silentex® system and is designed for high thermal and corrosion resistance. The Advantex® glass composition represents a technological advance in OCV™ Reinforcements’ commitment to provide value-added products to our customers. The Silentex® process, combined with Advantex® continuous roving, offers a robust solution to meet demanding acoustic requirements, increasing engine temperatures, reduced weight and volume, reduced back pressure, and lower overall cost of silencers. PRODUCT DESCRIPTION The ST1048 product is OCV™ Reinforcements’ 28μm 4800 tex Single End roving based on the Advantex® high temperature composition and is specifically engineered for use in the Silentex® process to minimize process interruptions and ensure overall efficiency. High density 25kg doffs of ST1048 roving are spliced together in a very precise manner to ensure package transfer that is transparent to the Silentex® process. ST1048 is designed to ensure that the strand consistently texturizes into 2,900 filaments to ensure that each muffler will be filled with continuous fibers, highly effective in attenuating sound and highly resistant to blowout. FEATURES AND PRODUCTS BENEFITS Annealing and softening point are over 65°C (117°F) higher than standard E glass Able to withstand increasing exhaust temperatures Stainless steel wool is not typically required to protect the fiber from the exhaust gas 5 times the fiber strength of basalt wool and over 2 times the fiber strength of E glass needle felts Fibers will remain continuous and resist blowout in the exhaust Nearly 3 times more resistant to degradation due to corrosive fluids found in typical exhausts than standard E glass Fiber strength will be retained even under the most corrosive conditions in the exhaust Linear density of 4800 tex Very high process efficiency Typical direct fill rates as fast as 36g/s/nozzle Narrow and consistent fiber diameter distribution Does not contain unfiberized beads like most basalt wool Consistent acoustic absorption Fibers not respirable into the deep lung Fill density can often be reduced over basalt preforms or needle felt Good processability in the Silentex machines Maintains high production efficiency Good strand texturization 18 x 40kg doffs with only 17 splices per pallet Individual doffs are spliced together No need to handle individual doffs Extremely high package density at 700kg per pallet Reduces floor space compared to ready texturized products

Open the catalog to page 1

Accelerated Corrosion 24H in Simulated Exhaust Fluid (pH2) Thermal durability basalt roving basalt uuool Rovings are available in a single-end internal-pull package. Each pallet weighed about 700kg. Pallets are stretch wrapped for load stability. All doffs are wrapped with Tack-Pak® or shrinkable film for protection during transport. Full doffs are available in 25 kg (55 lb.) weight and they can be packaged in bulk or Creel-Pak® format. More information is available in the Customer Acceptance Standards Unless otherwise specified, it is recommended to store glass fiber products in a cool,...

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

OPTISPRAY®

2 Pages

-

U101

2 Pages

-

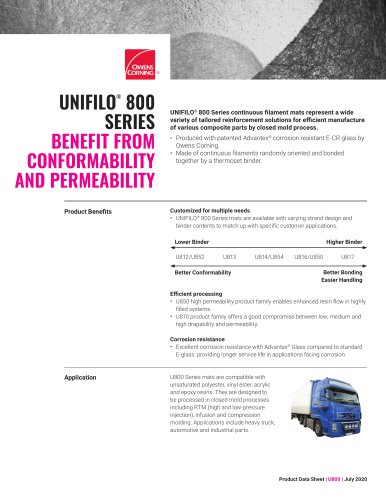

UNIFILO® 800

2 Pages

-

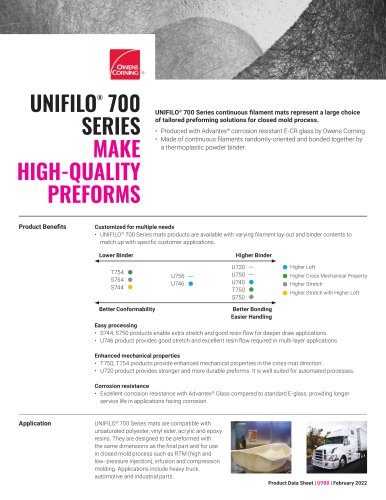

UNIFILO® 700

2 Pages

-

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

M723A

2 Pages

-

M705X1

2 Pages

-

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

FoodContact™

2 Pages

-

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

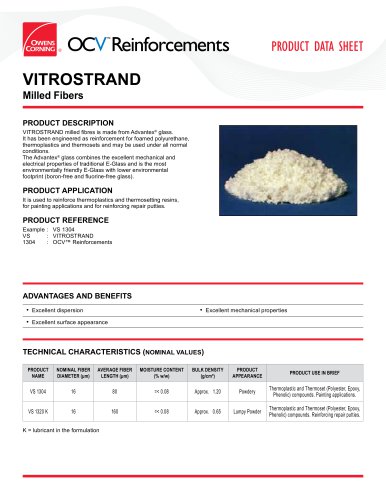

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

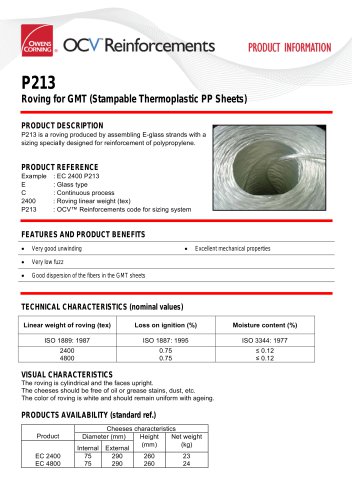

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

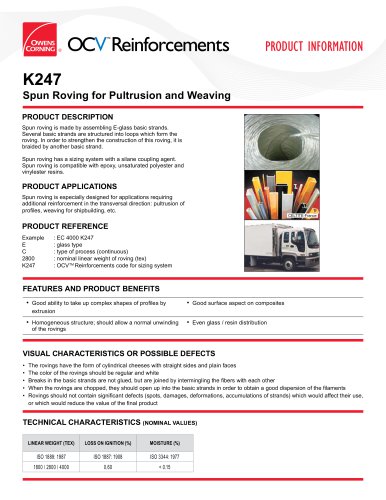

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

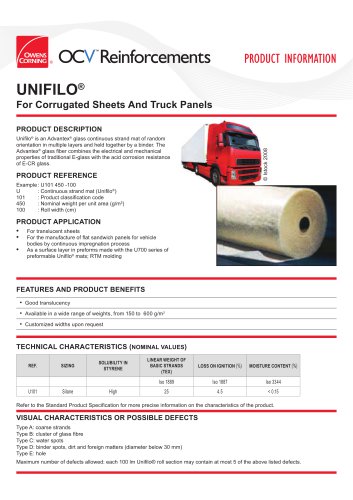

Unifilo® U101

2 Pages

-

OptiSpray H Roving

2 Pages

-

Thermopreg fabrics

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

Single_EndRovings_Range

2 Pages

-

SingleEnd_Roving_ST2070

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRov_973

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

GRC Spray Roving

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages