Catalog excerpts

PRODUCT INFORMATION Single-End Rovings (Type 30®) OCV™ Reinforcements is the pioneer in both Multi and Single-End roving and has been making glass for more than 50 years. OCV™ Reinforcements developed the Single-End Roving process and trademarked Type 30® over 30 years ago. OCV™ Reinforcements manufactures Single-End Rovings globally with advanced equipment, innovative surface chemistry and a commitment to process control. The result is a ready supply of products to meet the most exciting performance and cost requirements. Ongoing development work continues to refine the performance of single-End Rovings with one customer benefit in mind, increased productivity. PRODUCT DESCRIPTION Single-End Rovings are reinforcement products for filament winding, long-fiber thermoplastics, pultrusion, knitting and weaving applications with polyester (UP), vinylester (VE), epoxy (EP), phenolic (PN), polypropylene (PP), polyamide (PA) resin systems. Single-End Rovings are produced by pulling individual fibers directly from the bushing and winding them onto a roving package ready for shipment. The uniform distribution of a proprietary sizing system ensures an excellent resin-to-glass binding through uniform distribution of the binding agent. GLOBAL QUALITY OCV™ Reinforcements continues to meet ongoing customer demands for higher productivity, higher value products and excellent support. Single-End Rovings are produced with a global process, which ensures high quality and consistency in all regions of the world while meeting performance and cost requirements. Our worldwide technical and marketing network provides our customers with products and services that continue to meet evolving needs. ADVANTEX® AND SINGLE-END ROVINGS In recent years, OCV™ Reinforcements began making Single-End Rovings with the company's Advantex® glass fiber reinforcements. Advantex® glass fiber reinforcements combine the electrical and mechanical properties of traditional E-glass with the acid corrosion resistance of E-CR glass. Advantex® glass fiber reinforcements are compatible with all of the most widely used resin systems. Processability and production characteristics of Advantex® glass fiber reinforcements are comparable to traditional E-glass and FEATURES AND PRODUCT BENEFITS • Superior processing • Optimized to maximize equipment uptime • Fast wet-out • Increased productivity • Optimum package and pallet weight • Better productivity, less storage space, fewer pallet changes • Excellent laminate mechanical properties • Meets or exceeds physical properties requirements for a broad range of applications Excellent packaging run out and transfer More complete glass utilization and reduced labor cost

Open the catalog to page 1

Single-End Rovings (Type 30®) GLOBAL RANGE FOR THERMOSET RESINS PRODUCT REGION NA LA EMEA RESIN COMPATIBILITY AP UP VE EP PN PROCESS Fil. Winding Pultrision Weaving Muffler Filling 111A SE1200 SE1500 366 399 699 SEB400LS R25H 158B SE2348 SE2350 FW300 FW35 117A 202 ST2070 ST1048 ST2000 PACKAGING Rovings are available in a single-end internal-pull package. Each pallet weighed about 1 ton. Pallets are stretch wrapped for load stability. All doffs are wrapped with Tack-Pak® transport. Full doffs are available in weights of 20 kg (45 lb.) and 40 kg (88 lb.) regionally and they can be packaged in...

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

OPTISPRAY®

2 Pages

-

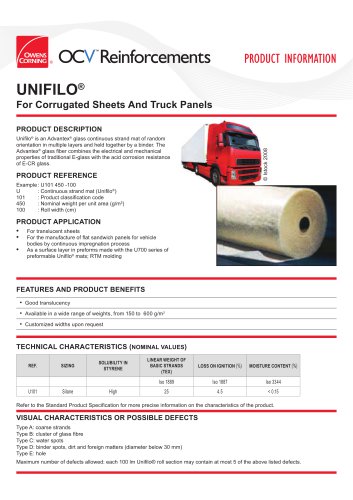

U101

2 Pages

-

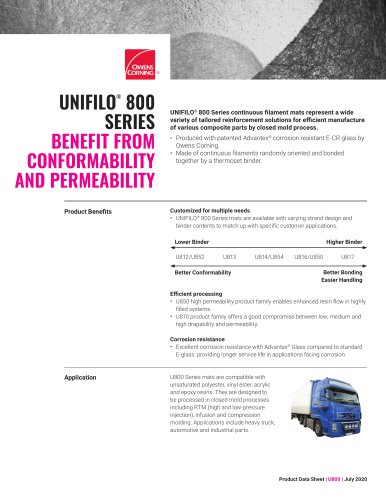

UNIFILO® 800

2 Pages

-

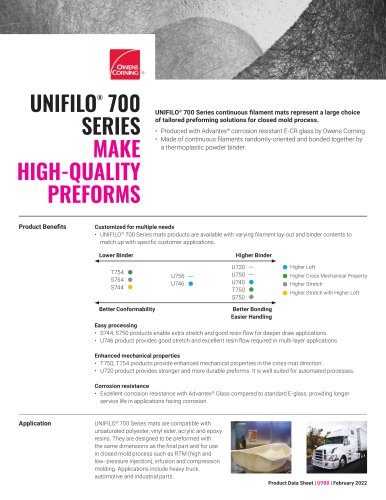

UNIFILO® 700

2 Pages

-

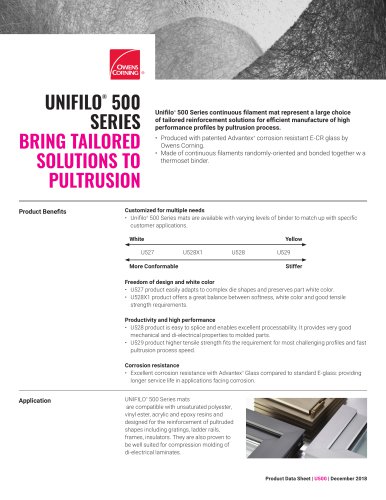

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

M723A

2 Pages

-

M705X1

2 Pages

-

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

FoodContact™

2 Pages

-

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

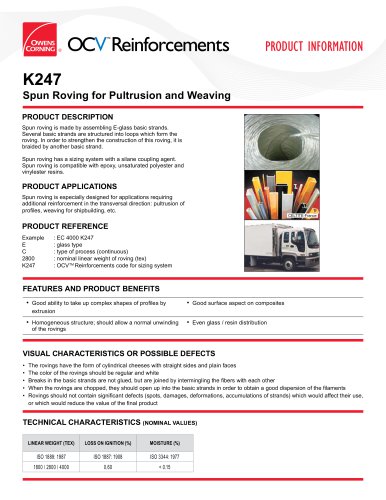

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

Unifilo® U101

2 Pages

-

OptiSpray H Roving

2 Pages

-

Thermopreg fabrics

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

SingleEnd_Roving_ST2070

2 Pages

-

SingleEnd_Roving_ST1048

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRov_973

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

GRC Spray Roving

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages