Catalog excerpts

PRODUCT INFORMATION Multi-End Roving for Input and Chopping PRODUCT DESCRIPTION The 973 Multi-End Roving is manufactured from a collection of continuous glass filaments, gathered, without mechanical twist, into multiple bundles. The filaments that make up the bundles are bonded together with a high performance polyester/vinylester compatible silane based sizing. The 973 sizing is compatible with polyester/vinylester resin systems as well as some polyurethane resins. 973 Roving is produced using Advantex® glass fiber. Advantex® glass fiber combines the electrical and mechanical properties of traditional E-glasses with the corrosion resistance of E-CR glass. PRODUCT APPLICATION Fiberglas® 973 Multi-End Roving is designed for use in the manufacture of sheet molding compounds for use in door skins, interior and exterior automotive parts and industrial parts. FEATURES AND PRODUCT BENEFITS • Excellent laminate properties First rate flow characteristics Excellent runnability Excellent sheet density Excellent choppability Excellent surface quality in low profile SMC Excellent wetting characteristics Optimum package and pallet weight TECHNICAL CHARACTERISTICS (NOMINAL VALUES) VISUAL CHARACTERISTICS OR POSSIBLE DEFECTS Roving Doffs are square-edged, cylindrical packages which are firmly and evenly wound and have a constant traverse length. The packages are designed to provide a smooth runout, and their geometry is controlled to maintain the desired run out performance. Unless otherwise specified, packages (Doffs) are connected using an 8-way air splice.

Open the catalog to page 1

Multi-End Roving for Input and Chopping PRODUCT AVAILABILITY • Air Spliced Tack-Pak® Wrap Vertical Creel-Pak® 973 Multi-End Roving should be stored dry, in its original packaging. The best conditions are temperature between 15 and 35°C and at a relative humidity between 35 and 85%. If the product is stored at low temperature (below 15°C) it is advisable to condition it in the workshop, for at least 24 hours before use, to prevent condensation. Static stacking of the pallets is possible one plus one (1/1), but it is recommended to use a plywood plate between the two pallets in order not to...

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

OPTISPRAY®

2 Pages

-

U101

2 Pages

-

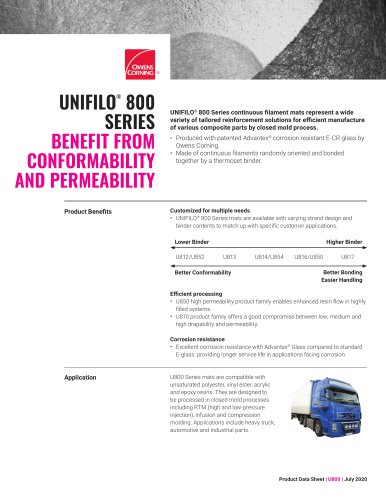

UNIFILO® 800

2 Pages

-

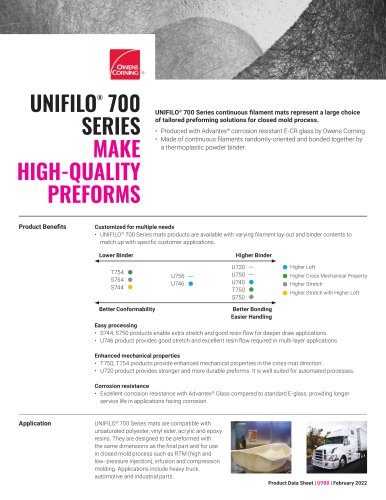

UNIFILO® 700

2 Pages

-

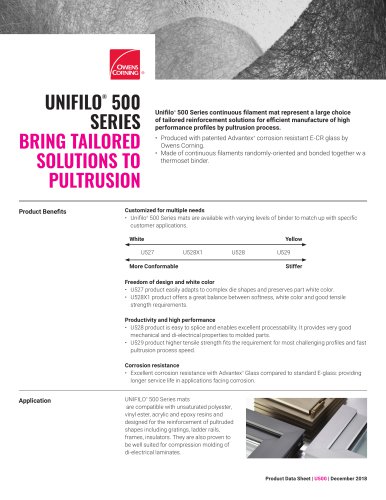

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

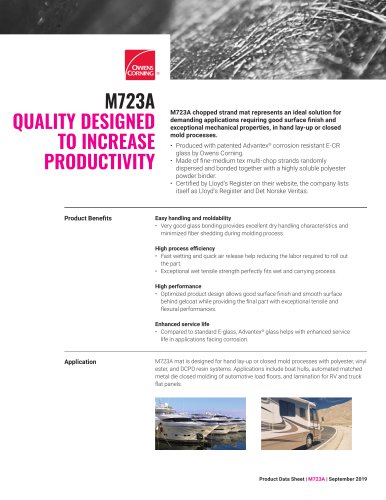

M723A

2 Pages

-

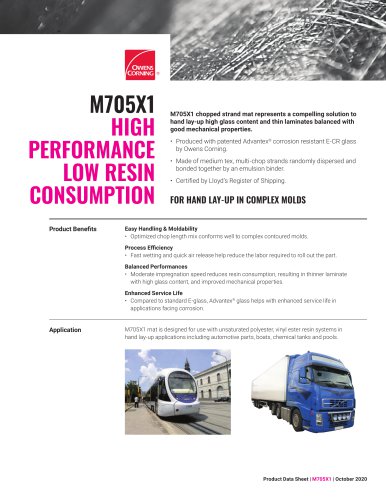

M705X1

2 Pages

-

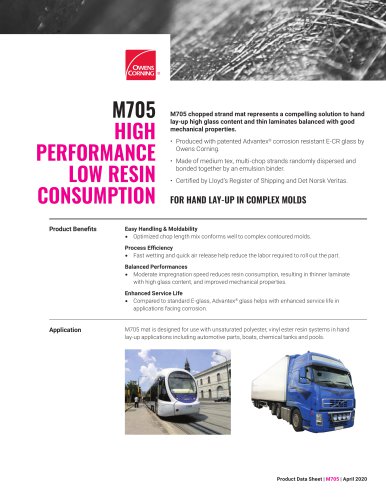

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

FoodContact™

2 Pages

-

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

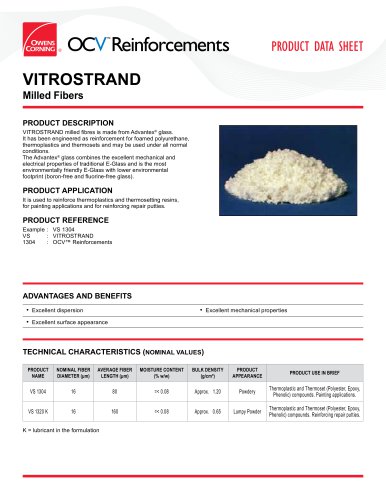

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

Unifilo® U101

2 Pages

-

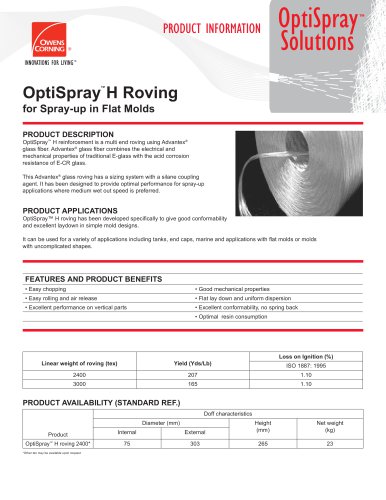

OptiSpray H Roving

2 Pages

-

Thermopreg fabrics

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

Single_EndRovings_Range

2 Pages

-

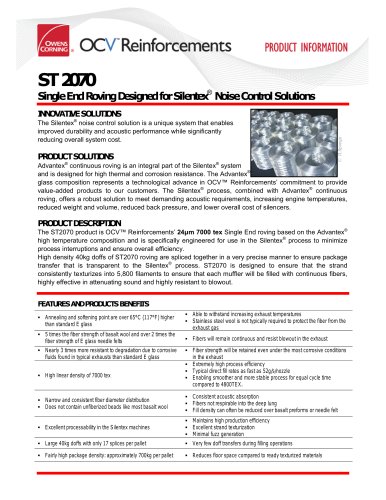

SingleEnd_Roving_ST2070

2 Pages

-

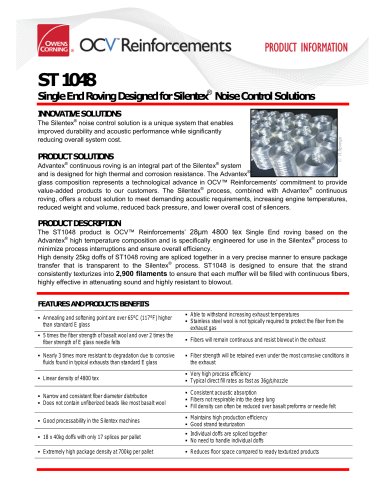

SingleEnd_Roving_ST1048

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

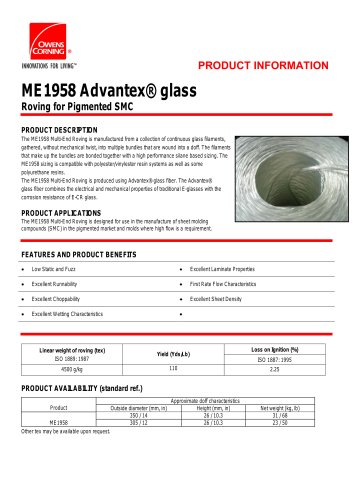

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

GRC Spray Roving

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages