Catalog excerpts

Cem-FIL® 54/76 GRC Spray Roving PRODUCT DESCRIPTION Cem-FIL® 54/76 is an Alkali Resistant glass fibre assembled roving designed for use in the manufacture of glass fibre reinforced concrete (GRC) composites by the simultaneous spray method. PRODUCT APPLICATION Cem-FIL® 54/76 is a spray roving with easy processing and incorporation, enabling the production of GRC elements with excellent finish and reproduction of detail. Cem-FIL® 54/76 provides very good mechanical performance and excellent durability to GRC composites. Cem-FIL® 54/76 is suitable for the fabrication of GRC in high humidity conditions. Cem-FIL® 54/76 has been tested and approved for use with the commonly used spray equipment. FEATURES AND PRODUCT BENEFITS • Alkali resistant glass* • Perfect for use with complicated profiles • Good unwinding • High reproduction of detail • Easy chopping • Excellent mechanical performance • High split efficiency • Makes Highly durable GRC element • Very easy incorporation into the matrix • Safe and easy to handle * Our fibres are manufactured with high Zirconia content in compliance with ASTM C1666/C 1666/M-07 and EN 15422 and under the recommendations of PCI and GRCA TECHNICAL CHARACTERISTICS (nominal values) Linear weight of Roving (tex) Linear weight of Strand (tex) ISO 1889 : 1987 ISO 1889 : 1987 ISO 1887 : 1980 ISO 3344 : 1977 2450 76 2.0 0.3 max Loss on Ignition % Moisture (%)

Open the catalog to page 1

Cem-FIL® 54/76 GRC Spray Roving Cem-FIL® 54/76 rovings are shrink-wrapped and are packed on pallets either with or without carton boxes. PALLET CHARACTERISTICS STORAGE Cem-FIL® 54/76 rovings should be stored away from heat and moisture, and in their original packaging. The best conditions are: • Temperature: 15 ºC – 35 ºC. • Humidity: 35 % – 65 %. If the product is stored at lower temperatures it is advisable to condition it in the workshop for at least 24 hours before use, to prevent condensation. OCV™ Reinforcements recommends using the material according to FIFO (first in, first out)...

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

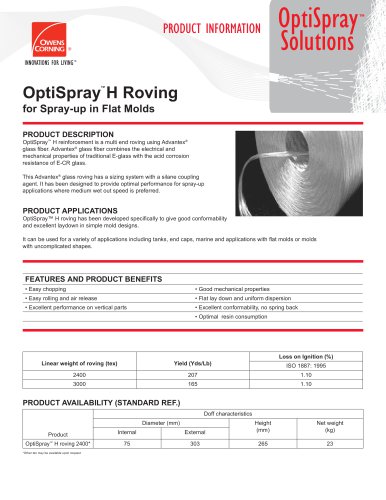

OPTISPRAY®

2 Pages

-

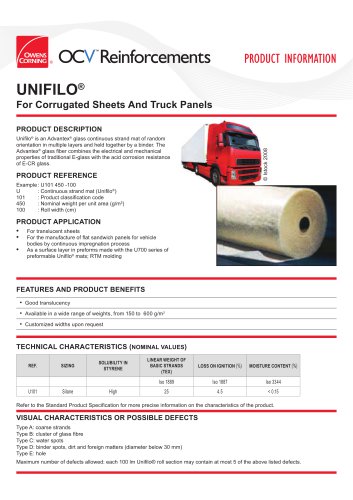

U101

2 Pages

-

UNIFILO® 800

2 Pages

-

UNIFILO® 700

2 Pages

-

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

M723A

2 Pages

-

M705X1

2 Pages

-

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

FoodContact™

2 Pages

-

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

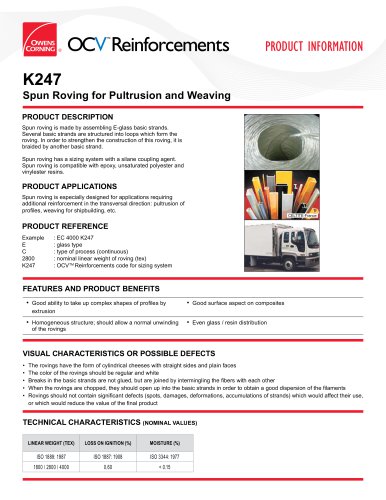

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

Unifilo® U101

2 Pages

-

OptiSpray H Roving

2 Pages

-

Thermopreg fabrics

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

Single_EndRovings_Range

2 Pages

-

SingleEnd_Roving_ST2070

2 Pages

-

SingleEnd_Roving_ST1048

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRov_973

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages