Catalog excerpts

PRODUCT INFORMATION PRODUCT DESCRIPTION Owens Corning FoodContact™ glass chopped strands have been designed to serve companies manufacturing, designing or distributing products that come into contact with food or drinking water, and help them comply with the new European regulation 10/2011, Jan.14, 2011, GMP regulations (2023/2006) and provide safer products. Our three new product offerings are optimized to meet design and performance needs of several key reinforced thermoplastics: FoodContact™ 210 for High Temperature resins, FoodContact™ 242 for PPO and FoodContact™ 295 for PA, PBT & PET. PRODUCT APPLICATION Ideal for usage in applications such as coffee machines, kitchen appliances, housewares, food processors and drinking water systems. Visit our website http://composites.owenscorning.com/foodcontact/index.html • FoodContact™ 210, 242 and 295 sizing chemistries are all compliant with European Union regulation 10/2011 and manufactured in compliance with GMP requirements of European Union regulation (2023/2006) • Optimized end-use performance with FoodContact™ 210 for use with high-temp. resins (PPS, LCP, PESU, PSU, PEEK etc); FoodContact™ 242 for use with PPO resins; and FoodContact™ 295 for use with PA, PBT and PET resins • Optimized handling and processing characteristics • Availability: all grades available for sampling upon demand > Enables our customers to provide products that meet new European Food Contact regulations to help insure product health and safety > Enables our customers to meet end-use mechanical performance requirements on food contact applications with composite properties comparable to today's industry standards > Ease of product processing with no change in equipment > Supply security with multi-regional manufacturing sites INJECTION MOLDED PROPERTIES Plse contact our technical & commercial team at foodcontact@owenscorning.com

Open the catalog to page 1

STORAGE - The chopped strands should be stored in a dry location and in their original packaging - Ideal conditions are between 10°C (50°F) and 35°C (95°F) with relative humidity between 35% and 65% - When properly stored, there is no known shelf life REGULATORY MSDS and SDS documents are available upon request and will be provided with the first order. OWENS CORNING COMPOSITE SOLUTIONS BUSINESS ASIA PACIFIC REGIONAL HEADQUARTERS UNIT 01,02,05,39/F, PUDONG KERRY PARKSIDE, 1155 FANG DIAN ROAD, PUDONG, SHANGHAI 201204, CHINA +86-21-6101 9666 OWENS CORNING COMPOSITE MATERIALS, LLC ONE...

Open the catalog to page 2All Vetrotex - OCV Reinforcements catalogs and brochures

-

M723B

2 Pages

-

M123

2 Pages

-

VL9202

2 Pages

-

P209

2 Pages

-

M113

2 Pages

-

P207

2 Pages

-

973 & 973CX1

2 Pages

-

OPTISPRAY®

2 Pages

-

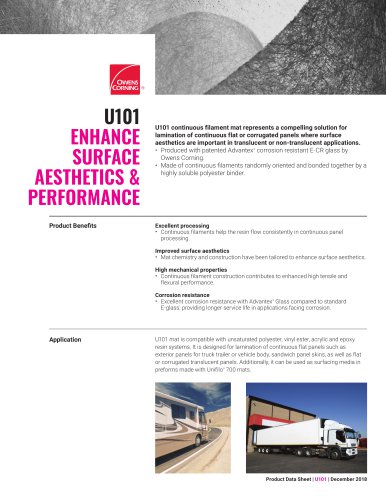

U101

2 Pages

-

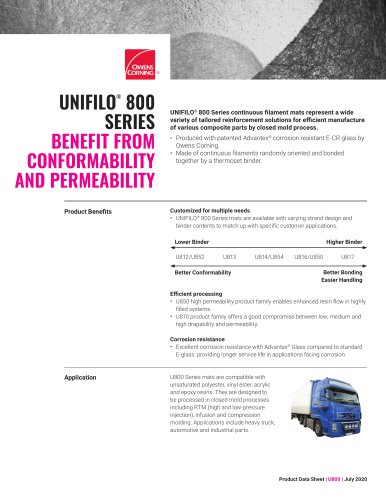

UNIFILO® 800

2 Pages

-

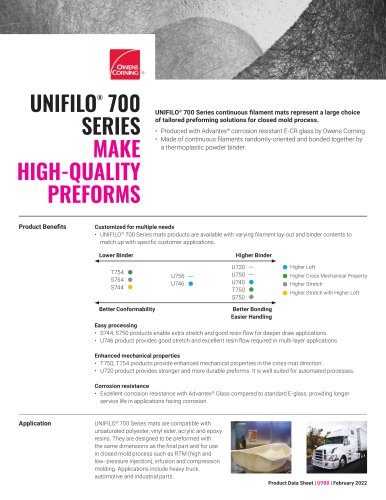

UNIFILO® 700

2 Pages

-

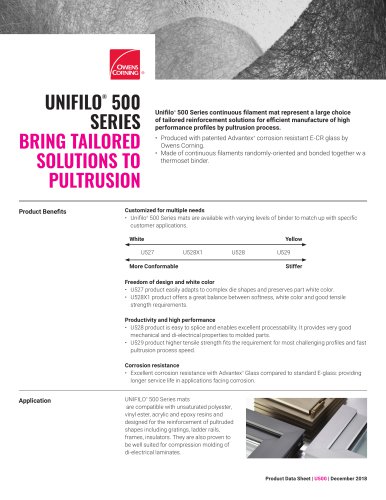

UNIFILO® 500

2 Pages

-

UNICONFORM®

2 Pages

-

M723A

2 Pages

-

M705X1

2 Pages

-

M705

2 Pages

-

M6 X1

2 Pages

-

M524-C64

1 Pages

-

M524-ECR30S

1 Pages

-

M524-ECR30A

1 Pages

-

OPTISPRAY® F

2 Pages

Archived catalogs

-

272 chopped strand 256

2 Pages

-

272 chopped strand benefit

2 Pages

-

Silentex® Machine

6 Pages

-

XStrand® H MCX24

2 Pages

-

111A

2 Pages

-

SE 1500 Roving

2 Pages

-

TYPE 30® SINGLE-END ROVINGS

2 Pages

-

Vitrostrand

2 Pages

-

Thermopreg Plates

2 Pages

-

ME1037

2 Pages

-

P213

2 Pages

-

SE4121

2 Pages

-

P249

2 Pages

-

K247

2 Pages

-

M103

2 Pages

-

E-CSM

2 Pages

-

M133

2 Pages

-

M720

2 Pages

-

M821B

2 Pages

-

M8643

2 Pages

-

Unifilo® U101

2 Pages

-

OptiSpray H Roving

2 Pages

-

Thermopreg fabrics

2 Pages

-

ME3023

2 Pages

-

SingleEndRov_Silentex

8 Pages

-

Single_EndRovings_Range

2 Pages

-

SingleEnd_Roving_ST2070

2 Pages

-

SingleEnd_Roving_ST1048

2 Pages

-

WUCS_Optiflow_790C

2 Pages

-

MultiEndRovingSMC_ME1958

2 Pages

-

MultiEndRovSMC_905A

2 Pages

-

MultiEndRov_956

2 Pages

-

MultiEndRovSMC_957

2 Pages

-

MultiEndRov_973

2 Pages

-

MultiEndRovSMC_985

2 Pages

-

MultiEndRovingSMC

2 Pages

-

MultiEndRov_P215

2 Pages

-

MultiEndRov_R07

2 Pages

-

MultiEndRov_R63SX3

2 Pages

-

SingleEndRovings_SE1200

2 Pages

-

MultiEndRov_P224

2 Pages

-

ChoppedStrandMats_M153

2 Pages

-

SingleEndRovings_SE1500

2 Pages

-

Unidirectional

2 Pages

-

Triaxial Fabrics

2 Pages

-

Quadraxial Fabrics

2 Pages

-

Double Bias fabrics

2 Pages

-

Biaxial Fabrics

2 Pages

-

Multimat

2 Pages

-

P218

2 Pages

-

PZ

2 Pages

-

Milled fibers REV

2 Pages

-

Multiconform

2 Pages

-

U543

2 Pages

-

U500

2 Pages

-

U800

2 Pages

-

U700

2 Pages

-

M534

2 Pages

-

M134

2 Pages

-

M153

2 Pages

-

M5

2 Pages

-

BMC P316

2 Pages

-

BMC R63SX1

2 Pages

-

BMC P317

2 Pages

-

BMC 979

2 Pages

-

GRC Spray Roving

2 Pages

-

TWINTEX® R PP

2 Pages

-

Roving for Chopping

2 Pages