Website:

Transfluid

Website:

Transfluid

Catalog excerpts

FLUID COUPLINGS

Open the catalog to page 1

PERFORMANCE CURVES STARTING TORQUE CHARACTERISTICS STANDARD OR REVERSE MOUNTING PRODUCTION PROGRAM SPECIAL VERSION (ATEX) DIMENSIONS (IN LINE VERSION) CENTER OF GRAVITY AND MOMENT OF INERTIA DIMENSIONS (PULLEY VERSIONS) SAFETY DEVICES OTHER TRANSFLUID PRODUCTS SALES NETWORK

Open the catalog to page 2

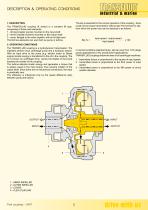

DESCRIPTION & OPERATING CONDITIONS The slip is essential for the correct operation of the coupling - there could not be torque transmission without slip! The formula for slip, from which the power loss can be deduced is as follows: The TRANSFLUID coupling (K series) is a constant fill type, comprising of three main elements: 1 - driving impeller (pump) mounted on the input shaft. 2 - driven impeller (turbine) mounted on the output shaft. 3 - cover, flanged to the outer impeller, with an oil-tight seal. The first two elements can work both as pump or turbine. input speed - output speed input...

Open the catalog to page 3

PERFORMANCE CURVES 2.1 Transfluid coupling fitted on electric motors With a motor connected directly to the load there are the following disadvantages: • The difference between available torque and the torque required by the load is very low until the rotor has accelerated to between 80-85% of the synchronous speed. • The absorbed current is high (up to 6 times the nominal current) throughout the starting phase causing overheating of the windings, overloads in the electrical lines and, in cases of frequent starts, major production costs. • Over-dimensioned motors caused by the limitations...

Open the catalog to page 4

STARTING TORQUE CHARACTERISTICS 2.2 CHARACTERISTIC CURVES : transmitted torque from fluid coupling : starting torque of the electric motor : nominal torque at full load : accelerating torque K type (standard circuit) CK type (circuit with a delayed chamber) CCK type (circuit with a double delayed chamber) NOTE: Above starting times are indicative only

Open the catalog to page 5

DELAYED FILL CHAMBER ADVANTAGES 3. TRANSFLUID FLUID COUPLINGS WITH A DELAYED FILL CHAMBER 3.1 SUMMARY OF THE ADVANTAGES GIVEN BY FLUID COUPLINGS A low starting torque is achieved and with the standard circuit in – very smooth start-ups a maximum oil fill condition because fluid couplings limit the torque to less than 200% of the nominal motor torque. It is possible to limit further the starting torque down to 160% of the nominal torque, by decreasing oil fill: however, this creates slip and working temperature increase in the fluid coupling. The most convenient technical solution is to use...

Open the catalog to page 6

STANDARD OR REVERSE MOUNTING 4. INSTALLATION 4.1 STANDARD MOUNTING Driver inner impeller 4.2 REVERSE MOUNTING Driver outer impeller Minimum possible inertia is added to the motor, and therefore free to accelerate more quickly. Higher inertia directly connected to the motor. During the starting phase, the outer impeller gradually reaches the steady running condition. For very long starting times, heat dissipation capacity is lower. The outer impeller, being directly connected to the motor, reaches synchronous speed instantly. Ventilation is therefore maximum from the beginning. If a braking...

Open the catalog to page 7

PRODUCTION PROGRAM CKRG - CCKRG CKRBP - CCKRBP CKRD - CCKRD CKCG - CCKCG CKDM - CCKDM CKDMBP - CCKDMBP 5.1 IN LINE KRG-CKRG-CCKRG KRB-CKRB-CCKRB KRD-CKRD-CCKRD KRG3-CKRG3-CCKRG3 KRM-CKRM-CCKRM EK KCG-CKCG-CCKCG KDM-CKDM-CCKDM N.B.: : coupling with elastic coupling. : KRG version, with brake drum (...KRB) or disc (...KRBP). : ...KR with output shaft. A flexible coupling has to be used; it is possible to place it (with a convenient housing) between the motor and a hollow shaft gearbox. : version with elastic coupling allowing removal of rubber elements without moving the machines. : coupling...

Open the catalog to page 8

PRODUCTION PROGRAM 6 MOUNTING 6.1 IN LINE VERSIONS MOUNTING EXAMPLES Fig. A Horizontal axis between the motor and the driven machine (KRG-CKRG-CCKRG and similar). It allows a radial disassembly without moving the motor and the driven machine (KCG-KDM and similar). Between a flanged electric motor and a hollow shaft gearbox by means of a bell housing (...KRD and EK). Vertical axis mounting between the electric motor and a gearbox or driven machine. In case of order, please specify mounting type 1 or 2. Between the motor and a upported pulley for high powers and heavy radial loads. N.B....

Open the catalog to page 9

SELECTION 8 SELECTION 8.1 SELECTION CHART The chart below may be used to select a unit size from the horsepower and input speed. If the selection point falls on a size limit line dividing one size from the other, it is advisable to select the larger size with a proportionally reduced oil fill. GENERAL REFERENCE HORSE POWER CHART HORSE POWER THE CURVES SHOW LIMIT CAPACITY OF COUPLING

Open the catalog to page 10

8.2 SELECTION TABLE Fluid coupling for standard electric motors. NB: THE FLUID COUPLING SIZE IS TIED TO THE MOTOR SHAFT DIMENSIONS

Open the catalog to page 11

For frequent starts or high inertia acceleration, it is necessary to first carry out the following calculations. For this purpose it is necessary to know: For simplicity of calculation, ignore the heat dissipated during acceleration. Coupling temperature rise during start-up is given by: - input power - input speed - power absorbed by the load at rated speed - speed of driven machine - inertia of driven machine - ambient temperature where tL = minimum working time In addition to the heat generated in the coupling by slip during steady running, heat is also generated (as calculated above)...

Open the catalog to page 12

Trasmission via belts. From selection graph. on Tab. A, selected size is 12K. A) Acceleration time From curve Tf 5078-X (supplied on request) slip S = 4% nu kcal/°C kcal/°C kcal/°C C) Max working cycles per hour

Open the catalog to page 13

SERIES 7 ÷ 19 - KRG - KRB - KRBP - CK... - CCK... 9. DIMENSION (with brake drum) (with brake disc) CKRG - CCKRG In case of installation on shafts without shoulders, please contact Transfluid taper bush cylindrical bore DIMENSIONS ARE SUBJECT TO ALTERNATION WITHOUT NOTICE Size CKRG CCKRG brake disc CKRG CCKRG D BORES RELATIVE TO TAPER BUSHES WITH A KEYWAY ACCORDING TO ISO 773 - DIN 6885/1 PARTICULAR CASES: • CYLINDRICAL BORE WITHOUT TAPER BUSH WITH A KEYWAY ISO 773 - DIN 6885/1 •• CYLINDRICAL BORE WITHOUT TAPER BUSH, WITH A REDUCED KEYWAY (DIN 6885/2) ••• TAPER BUSH WITHOUT KEYWAY – FOR …KRB...

Open the catalog to page 14All Transfluid catalogs and brochures

-

HYBRID & ELECTRIC TECHNOLOGY

16 Pages

-

Hybrid Booster

4 Pages

-

POWER TRANSMISSION EQUIPMENT

5 Pages

-

KX

4 Pages

-

RBD

7 Pages

-

B3M-BM-BMS FLEXIBLE COUPLINGS

12 Pages

-

GEAR COUPLINGS P SERIES

12 Pages

-

SL SPRING LOADED BRAKES

4 Pages

-

SH-SHC OIL ACTUATED CLUTCHES

8 Pages

-

KSL

8 Pages

-

KPTO

4 Pages

-

HF - MFO POWER TAKE OFF

8 Pages

-

STELLADRIVE

8 Pages

-

Power Shift Transmissions

8 Pages

-

Battery pack

4 Pages

-

Electric propulsion system

28 Pages

-

Marine transmissions

16 Pages

-

High Speed

5 Pages

Archived catalogs

-

TOWERCLUTCH

5 Pages