Catalog excerpts

Kubria® Cone Crushers

Open the catalog to page 1

Kubria®Cone Crushers Modern Hard Rock Crushing ThyssenKrupp Fordertechnik development work has become processing equipment. Customers all over the world benefit from our innovative customized designs ThyssenKrupp Fordertechnik always offer complex solutions often developed in co-operation with users. Reliable, safe, economic,... ThyssenKrupp Fordertechnik. Advanced technology means highest outputs, low operating cost, minimum maintenance, maximum safety. chippings in the natural rock • Lime and cement industnes • Refractory industry • Other primary industry areas. • High throughputs • High...

Open the catalog to page 2

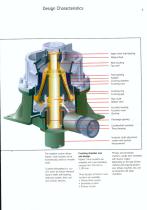

Design Characteristics Upper main shaft bearing Material feed Wear bushing Feed opening Crushing chamber Crushing cone Crushing ring Main shaft Bottom shell Eccentric bushing Eccentric insert Discharge opening Countershaft assembly Thrust bearing Hydraulic shaft adjustment system with position The modular system allows Kubria" cone crushers to be economically used for versatile cific series all feature identical bottom shells with bearing, hydraulic system, drive unit Crushing chamber size Kubria " cone crushers are available with cone diameters Three designs of Kubria1 cone ■ Tertiary...

Open the catalog to page 3

Kubria' crushing In tertiary as well as secondary crushers the crushing chamber feed opening and geometry appropriate adapters. For special crushing tasks anvil-type crushing mantles considerably improve the effi- ciency and provide a uniform wear across the crushing chamber height compared to customary designs. feed opening in the upper area crushing effect on the smaller feed lumps while coarse same time. This means: : Large wear volumes Reduced wear part costs Crushing members made of special materials are available for feed materials causing heavy wear. Thrust bearing: The hydrostatic...

Open the catalog to page 4

Monitoring, Control and Hydraulic Systems reliable control and monitoring system especially designed for Kubriaa cone crushers. monitoring functions required width under load within Q Easy check of the wear status crushing cone from being reduced when crushing members have reached the wear limit 3 Main shaft position is automatically kept constant desired kW range preventing dropping below a minimum control panel circulation lubrication system ® High degree of safety when foreign matter is fed which Large shaft lowering stroke (within 0.2 seconds) in case foreign matter to pass a Maximum...

Open the catalog to page 5

Drive rating 1) Crushing chamber design primary (G) with different feed opening widths 2) Depending on selected crushing members Weights indicated do not include drive unit, electrics, controls 3) Depending on the crushing task (properties of feed matenal, product Sutyect to guide value changes Installation layout with fitting dimensions

Open the catalog to page 6

Research, Development ThyssenKrupp Fordertechnik are attaching great importance Committed employees, tread new paths together with the innovative power, flexibility successful co-operation with The KF Cone program used for designing crushing chambers of cone crushers is only one development efforts. The program's basic model • Bulk density and/or solids compression point • Gap width, stroke, angle of inclination and/or nip angle crushing chamber. Our services inlcude project research, damage analyses, conjunction with a worldwide after-sales service which also covers the equipment of other...

Open the catalog to page 7

ThyssenKrupp Fordertechnik Processing Industry Delivery program Crushing technology • Stationary, semi-mobile and mobile crushing plants • Gyratory crushers • KUBRIA cone crushers • MAMMUT' single-shaft hammer crushers • TITAN* double-shaft hammer crushers • Impact crushers • Roll crushers e SIEBRA' swivel-arm crushers Screening technology • Linear vibrating screens • Circular vibrating screens • Elliptical vibrating screens • Eccentric vibrating screens • Grizzly primary screens • Vibrating screen feeders • Unbalance drive units Grinding technology • Ball mills • Hammer mills • Roll mills...

Open the catalog to page 8All ThyssenKrupp Fördertechnik catalogs and brochures

-

Open Pit Mining Equipment

28 Pages

-

Jaw Crusher

12 Pages

-

Rotary Plow Feeder

4 Pages

-

Polysius

12 Pages

Archived catalogs

-

Catalog-2004

22 Pages