Catalog excerpts

Marine Fenders

Open the catalog to page 1

About TekMarine From its base in the United States, TekMarine Systems LLC designs and supplies advanced marine fendering and mooring systems to ports, harbors and waterways across the world. We bring a wealth of engineering and market experience to each project. Our fender solutions range from simple modules to the most sophisticated engineered systems. We supply every type of berth, including passenger terminals, bulk and RoRo ports, Oil and Gas installations and naval facilities. We offer full support at each step from early concept discussions through to design and detailing, material...

Open the catalog to page 2

Q Foam Fender Technology The same advanced materials technology goes into every TekMarine foam fender and buoy. A filament-reinforced outer layer shields the closed-cell polyethylene foam core. While the fender's skin shrugs off wear and tear, the foam provides buoyancy and absorbs berthing energy. Foam grades With grades from Standard to Ultra High Capacity, you can select a fender for any application. Softer grades provide a gentler reaction, while stiffer grades can cope with much higher impact energies. Durable skin The polyurethane elastomer skin provides a highly durable, nonmarking...

Open the catalog to page 3

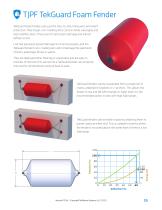

TJPF TekGuard Foam Fender TekGuard Foam Fenders are used for ship-to-ship maneuvers and wharf protection. Their tough, non-marking skins come in white, naval gray and high visibility colors. They resist UV and ozone damage and will not deflate or sink. Low hull pressures prevent damage to incoming vessels, and the TekGuard fender’s non-marking skin will not damage the paintwork of liners, passenger ferries or yachts. They are deployed either floating or suspended, and are easy to relocate. At the end of its service life a TekGuard fender can simply be returned for refurbishment and put back...

Open the catalog to page 4

TJDF Donut Fender Filament reinforced polyurethane elastomer skin Steel core TJDF Donut Fenders guide vessels at lock entrances, berth approaches and turning points. The donut floats around a tubular pile and follows changes in the water level. Installation could not be easier: simply lower the fender over the monopole until it floats. The donut’s durable, low-friction bearings allow free movement with minimal maintenance. Its closed-cell foam core makes the donut impossible to sink, burst or deflate. The filament-reinforced, polyurethane elastomer skin is exceptionally tough. Filament...

Open the catalog to page 7

Standard Capacity High Capacity Energy Extra High Capacity Super High Capacity Ultra High Capacity Energy

Open the catalog to page 8

Steel panel with welded stud 0 UHMW-PE Facings TekMarine protects every fender panel with top quality UHMW-PE (Ultra High Molecular Weight Polyethylene) facings. Impact resistant and very low in friction, UHMW-PE allows vessels to move smoothly past a fender system without snagging or abrasion. It is also popular for heavy duty impact protection where fenders are not required. Easy to machine and install, UHMW-PE comes in many colors and several quality grades. UHMW-PE does not rot, split or decay and does not suffer from UV or ozone damage. It is fully recyclable. Open steel Timber...

Open the catalog to page 9

Friction comparisons Material The coefficient of friction of UHMW-PE varies according to the material grade and the pressure applied to the panel's surface. These coefficients of friction only apply to smooth contact surfaces. Source: BS 6349-4:2014 For more information please consult TekMarine. Version 001d / Copyright TekMarine Systems LLC, 2015

Open the catalog to page 10

Anchors and Fixings A fender system relies on the best quality fixings and accessories to perform properly. Large or heavy-duty fenders need chain systems to manage shear, tension and weight. These comprise open or stud-link chain, tensioners and shackles. Cast-in or resin anchors connect the chain systems and brackets to the quay structure. Various material grades and finishes are available: please ask TekMarine for details. Typical chain system Cast-in anchor Chain Chain Open-link Chain 56 Version 001d / Copyright TekMarine Systems LLC, 2015

Open the catalog to page 11

Brackets are purpose designed for every project. Please ask TekMarine for details. Version 001d / Copyright TekMarine Systems LLC, 2015

Open the catalog to page 12

Anchors are available in galvanized or stainless steel finishes, in various strength grades and in metric or inch sizes. Ask TekMarine for details if the required specification is not listed. Cast-in type Cast-in anchors are preferred for new concrete structures. The threaded anchor links via a long tail to an anchor plate, for even load distribution. * Dimension A varies according to the thickness of the bracket or fender foot and should always be calculated. Chemical type Chemical anchors are used for existing concrete structures. Please ask about glass grout capsules and other...

Open the catalog to page 13

Standard manufacturing and performance tolerances apply to all TekMarine fenders. TekMarine may agree to smaller tolerances in special cases. Please ask TekMarine for tolerances of types not listed below. Unless otherwise listed or agreed with TekMarine, tolerances are ±20%. Version 001d / Copyright TekMarine

Open the catalog to page 14

Important note US customary units are listed for your convenience in this catalog, however figures in metric prevail throughout. Useful software At the time of publication, third-party unit conversion tools include: Convert for Windows: https://joshmadison.com/convert-for-windows/ NumericalChameleon: http://sourceforge.net/projects/numchameleon/ TekMarine offers no warranty for nor makes any claims as to accuracy or fitness for purpose of these programs. Version 001d / Copyright TekMarine Systems LLC, 2015

Open the catalog to page 15

TEKMARINE SYSTEMS LLC 9595 Six Pines Drive, Suite 8210 The Woodlands Houston, TX 77380, USA phone +1 832 631-6104 email sales@tekmarine.com web www.tekmarine.com Catalogue version 001d

Open the catalog to page 16All TekMarine Systems LLC catalogs and brochures

-

Marine fenders

8 Pages

-

Rolling Fender

6 Pages

-

Pneumatic Fenders

14 Pages

-

Tug Cylindrical Fenders

14 Pages

-

TRA Arch Fender

12 Pages

-

TPA Arch Fender

13 Pages

-

TCY Cylindrical fender brochure

10 Pages

-

TJUE Element Fender

18 Pages

-

Parallel Motion Fenders

14 Pages

-

TCL Cone fender brochure

18 Pages

-

TCN Cone fender brochure

18 Pages