Catalog excerpts

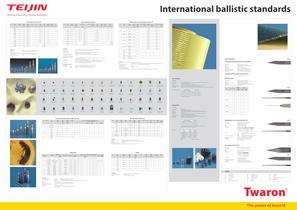

International ballistic standards NIJ Standard 0101.04, USA Class I II-A II TestBullet BulletProducer BulletVelocity [m/s] [ft/s] Max. BFD Max. BFD [m] [mm] 2.6 40 329 +- 9 1080 +- 30 5 44 Angle Test [° Nato] Wet test yes/no Padding down yes/no No. of shots per panel No. of tests 0° 4x 30° 2x yes only yes 6 4 .22 caliber LR LRN not spec. .380 ACP FMJ RN not spec. 6.2 95 322 +- 9 1055 +- 30 5 44 0° 4x 30° 2x yes only yes 6 9 mm FMJ RN not spec. 8.0 124 341 +- 9 1120 +- 30 5 44 0° 4x 30° 2x yes only yes 6 not spec. 11.7 180 322 +- 9 430 +- 10 5 0° 4x 30° 2x yes only yes 9 mm FMJ RN not spec. 8.0 124 367 +- 9 1205 +- 30 5 44 0° 4x 30° 2x yes only yes 6 not spec. 10.2 158 436 +- 9 1430 +- 30 5 44 0° 4x 30° 2x yes only yes 6 not spec. .44 Mag. JHP not spec. III 7.62 mm Nato FMJ not spec. IV .30 caliber M2 AP not spec. 8.0 124 436 +- 9 1430 +- 30 5 15.6 240 436 +- 9 1430 +- 30 5 9.6 148 848 +- 9 2780 +- 30 15 10.8 166 878 +- 9 2880 +- 30 15 44 44 44 44 yes only yes 0° 4x 30° 2x yes only yes 0° yes only yes 0° 9 mm II-A Remington 4 6 11.7 352 +/- 9 325 +/- 9 1155 +/- 30 4 III 8.0 398 +/- 9 379 +/- 9 124 1305 +/- 30 436 +/- 9 408 +/- 9 1430 +/- 30 yes only 2 1 IV .30 caliber 8.1 448 +/- 9 430 +/- 9 125 1470 +/- 30 conditioning 1410 +/- 30 Speer Speer 15.6 436 +/- 9 1430 +/- 30 - 148 0° 4x yes 6 Class Bullet- Bullet- Bullet- Producer Weight Velocity [g] [m/s] 5 44 0° 4x [ft/s] 44 5 0° 4x 44 0° 4x 6 yes 6 30/45° each 1x 5 44 0° 4x 6 44 0° yes 6 4 dry 8 4 - 8 4 JSP Remington 166 15 44 0° yes 1-6 2880 +/- 30 dry 9 mm FMJ DM 11 A1B2 5 44 dry 8 4 dry Dyn. Nobel HG1 4 dry 9 mm FMJ - 6 6x 0° 6 45°, 3x 0°, 45°, 0° 45°, 0°, 0° 6x 0° 6 45°, 0°, 0° 3 3x Size M 6 6x 0° 1x Size L 25 6 45°, 0°, 0° 6 6x 0° 1x Size L 6 45°, 0°, 0° 8.0 2x Size S Dyn. Nobel 6 6x 0° 6 45°, 0°, 0° 10.2 2x Size S Remington Federal Tactical 62 3 6 6x 0° 6 45°, 0°, 0° 2x Size S 10 25 3 3x Size M 6 6x 0° 1x Size L 750 +- 15 6 Rifle BAE Systems Nato Ball 144 Calibre L2 A2 BAE Systems 25 2 3 0° no 10 25 2 3 0° no 10 25 2 1 0° - 9.7 L40A1 Shotgun Winchester 1 oz. 28.4 12 gauge Rifled Lead Slug 437 True cylinder 12RS15 or 12RSE SG1 Particularities: • Measurement back face deformation: • UPL: • Backing material/ plasticity: • Temperature test: • V50 requirements: • Min. distance from the edge: • Min. distance from previous shots: • MQT (Manufacturers Quality Testing) 10 d at 65°C (149°F) and 80% RLH + 24h between -15°C and + 90°C + 2 drops. Conditioned: 24 shots (4 plates). No penetration below max. ref. speed. Conditioned: 12 shots (2-12 plates). No penetration below max. ref. speed. 10 435 +- 25 Nato Ball Calibre 830 +- 15 850 +- 15 Rifle 7.62 mm RF2 yes 9.3 7.62 mm yes 45°, 3x 0°, 45°, 0° LE223T3 RF1 yes 45°, 3x 0°, 45°, 0° 4.01 Bonded 25 158 Nato 5 3x Size M 1x Size L 455 +- 10 (24 shots) yes 45°, 3x 0°, 45°, 0° 124 R357M3 25 3 3x Size M 1x Size L 5 yes 45°, 3x 0°, 45°, 0° 158 DM 11 A1B2 3 3x Size M 25 yes 45°, 3x 0°, 45°, 0° 2x Size S 5 yes 45°, 3x 0°, 45°, 0° 10.2 Remington .357 Mag. 6 2x Size S 5 430 +- 10 HG2 44 3 3x Size M 1x Size L 4 wet 5 diff. sizes specified. Manufacturer has to choose range of sizes. Smallest and largest size have to be tested. 50/50% for perforation and BFS test. Tumbling for 10 d at 65°C (149 °F) and 80% RLH with 5 +/- 1 rpm (72.000 +/- 1500 rotations). New: 120 shots (10 panels) each caliber largest size. No penetr. below max. ref. speed, (V0.5 new ≥ Vref. new) Conditioned: 24 shots (2 panels) for each caliber largest size. No penetration below max. ref. speed. Shots 4, 5 and 6 have to be within a 100 mm (3.94”) circle. 45°, 0°, 0° down 3 124 R357M3 .357 Mag. 8 Particularities: • Backing material: Roma No. 1, 19mm +- 2mm, all indiv. values > 16 < 22 mm (1.03 kg sphere from 2m height). • Wet test: 30 min. vertical immersion, 10 min dripping of the unaged panels. • Temperature test: No • Measurement BFS: Shot No. 1, 2 and 3 < 44mm, if not estimated probability of BFD >44 mm has to be < 20%; also measured for aged panels, but no fail criteria if > 44mm. • Min distance from the edges: Lighter bullet min. not greater than 51 mm (2”), heavier bullet min. not greater than 76 mm (3”). • Min distance from previous shots: 51 mm. yes/no 2x Size S 5 390 +- 10 4-24 wet [° Nato] 3x Size M 10.2 365 +- 10 JSP - Padding panel [mm] Shooting Angle 2x Size S 4 R357M3 Carbine 5.56x45 Particularities level III and IV: • Conditioning: • V50 requirements: level III level IV [m] 390 +-10 HG3 Particularities level II-A, II and III-A: • Panel sizes: • Conditioning: • V50 requirements: • Shoot pattern: shots per 8.0 8 .357 Mag. JSP Particularities: • Backing material: Roma No. 1 19mm +- 2mm (1.03 kg sphere from 2m height) • Wet test: 3 min spraying from each side expect the V50 panels • Temperature test: No • Measurement back face deformation: Shot No. 1 + shot No. 2 or 3 (higher velocity fair hit) • V50 requirements: level I, II-A, II and III-A additional 2 panels V50 using 9 mm • Min distance from the edges: 76 mm No. of vest panels 158 HG1/A (24 shots) 878 +/- 9 No. of UPL 365 +- 10 dry 2780 +/- 30 10.8 Max. BFD 1x Size L 8 wet yes 30/45° each 1x 15 124 wet yes 30/45° each 1x 44 Dyn. Nobel Distance 8.0 wet 6 30/45° each 1x 5 DM 11 A1B2 wet 6 yes 0° 4x 9 mm FMJ wet yes 30/45° each 1x 5 cond. wet 30/45° each 1x 847 +/- 9 not spec. not spec. 44 1340 +/- 30 9.6 5 408 +/- 9 240 M2 AP 2 panel 1340 +/- 30 FMJ 6 yes/no 1245 +/- 30 10.2 158 7.62 mm Nato [° Nato] 1065 +/- 30 JHP 6 and new 355 +/- 9 Remington .44 Mag. No. of tests shots per 1165 +/- 30 JSP III-A No. of down conditioned 373 +/- 9 FMJ RN .357 SIG Padding Test [ft/s] Remington .357 Mag. Angle [mm] [m] 1225 +/- 30 FMJ 9 mm Max. BFS TestBullet [gr.] [m/s] 8.0 Remington HOSDB Body Armour Standards (2007), UK unaged 180 .40 S&W II Distance 124 FMJ RN FMJ FN 0° 4x 30° 2x Bullet- Velocity new 4 6 BulletWeight [gr.] 4 44 BulletProducer [g] 4 .357 Mag. JSP TestBullet 4 .40 S&W FMJ RN Class 4 9 mm FMJ RN III-A BulletWeight [g] [gr.] NIJ Standard 0101.06, USA STAB STANDARDS P1/B TECHNISCHE RICHTLINIE APRIL 2003, GERMANY BFD to be measured after each shot Upper prediction limit for BFD, is calculated based on the 0° BFD values measured on all medium size test samples Roma No. 1 15mm +- 1.5mm (1.043 kg sphere from 1.5m height) No No V50 test required 50 mm 50 mm MQT 1 and MQT 2 to be conducted after a specific No. of armors being produced to ensure quality • Test method: • Backing material: • Blade: • Stab Energy: • Angle of attack: • No. of attacks: • Max. penetration into backing: • Measurement of penetration: • Min. distances: Drop test Weible clay (plasticity as for shooting) Engineered test blade P1B (High Speed and Carbide) 25 J (2.38kg, 1.07m) 0°; in case of overlapping also 65° 3x roomtemp.; 3x climat.; 3x 80/70°C; 3x -20°C 20mm (max. deformation incl. penetr. 40 mm) Cutting into the clay to the deepest point of the mark 75 mm from the edges and any previous attack Technische Richtlinie March 2008, Germany • Test method: see VPAM May 2009, Class K1 MIL-STD-662F Test Method: .22 LRHV lead RN 2.6 g .22 LR lead RN 2.6 g 5,45x18 FMJ st. core 2.5 g 6.35 Browning FMJ SC Geco 3.2 g .22 Win. Mag. FMJ SC 2.6 g 7.62x25 Tokarev FMJ SC 5.5 g 7.62x25 Tokarev CZ FMJ st. core 5.5 g 7.62 x 25 Tokarev China FMJ st. core 5.5 g 7.62x25 Tokarev Russia FMJ st. core 5.5 g 9x19 Para FMJ SC DM 11 A1 B2 8 g Idem.shot in 90º (0 º) direction Idem.shot in 25º (65 º) direction 9x19 Para FMJ SC sintox tin plated 8 g DM 41 DAG VPAM May 2009 • Backing material: Weible clay (plasticity as for shooting) • Blade: Engineered test blade P1B (Wenger S.A. Switzerland) • No. of attacks: 3x roomtemp (+20°C); 3x 70°C; 3x -20°C • Measurement of penetration: Cutting into the clay to the deepest point of the mark • Min. distances: 50 mm from the edges and 80 mm from any previous attack • Potentional weak areas have to be tested with additional attecs at 65° Witness system: Striking angle: Yaw: Distances: Complete penetration: V50 definition: Aluminum alloy sheet 2024 T3, 0.51mm thick, tensile strength 440N/mm², 15,2cm behind armour Has to be specified by contractor Max. yaw 5° (measured for each shot by a yaw card) At least 2 projectile diameters from any previous impact, disturbed area, crack or edge Any projectile which perforates the witness system (light shines through) “Average of an equal number of highest partial and lowest complete penetration velocities in a spec. velocity range” Class No. of shots/velocity span: No. of shots required 9x18 FMJ st. core Makarov DDR 6 g Idem.shot in 90 º (0 º) direction 9x19 Para FMJ SC MK2Z 7.5 g 9x19 EMB 5.3 Hirtenberger 9x19 Para Action III brass 6 g 9x19 SXT + P + Winchester SC 8.2 g 9x19 FMJ SC Remington (NIJ) 8 g 9x19 FMJ SC Fame Peru 8.2 g 9x19 Para FMJ st. core Brigant 6.5 g [ft/s] 18 60 4 4 27 90 6 0x10 Para FMJ st. core Czech 6.5 g [m/s] 2 6 30 100 8 9x19 Para FMJ SC Fiochi sintox 7.5 g complete penetr. 2 9x19 Para FMJ SC m39/B 6.9 g Angle [°] Velocity span partial penetr. 9x19 Para FMJ SC Norma 19022 7.5 g Energy [J] 8 38 125 15 K1/D1 25 Has to be specified by contractor 25 K2/D2 9x19 Para FMJ SC Pist Pat 41 7.5 g 9 mm THV Afrika copper 3.1 g 9 mm Action 4 9 mm QD PEP 9 mm SeCa .357 Mg. JSP 10.2 g .357 Mag. MSF brass 7.1 g .357 Mag. Geco FMJ CB SC 10.25 g .357 Mag. FMJ FN SC Norma 19106 10.2 g .357 Mag. THV brass 3 g .380 ACP FMJ RN SC 6.2 g .38 Special RN lead 10.2 g 40 .38 Special JSP Speer 4217 10.2 g 40 Stanag 2920 K3/D3 Test Method: .38 Special SWC Speer 4623 10.2 g .40 S & W FMJ SC 11.7 g .44 Mag. SWC 15.6 g .44 Mag. FMJ FN SC 15.5 g .44 Mag. JSP 15.6 g .44 SJHP 15.6 g .45 Auto 11.5x23 FMJ SC 14.9 g Kaliber 12/70 Brenneke 31.5 g Stanag FSP 0.237 g/3.7 gr Stanag FSP 0.325 g/5 gr VPAM SK L TestBullet 2 BulletProducer 9mm Luger BulletWeight [g] [gr.] Distance [m] 8,0 ± 0,1 DAG, DM41 BulletVelocity [m/s] [ft/s] 360 ± 10 5 + 0,5 No. of shots performed under following conditions 1 panel for each kind of test 0° 65° 3+1 Class 3 0° contact shot 0° climat. 0° -20°C 0° +80/70°C 3 3 3 DAG, DM41 8,0 ± 0,1 415 ± 10 5 + 0,5 MEN 6,0 460 +- 10 RUAG 6.1 460 +- 10 3+1 3 3 Max. BFD Angle Wet test [m/s] [m] [mm] [° Nato] Makarov PM 9mm Fe 57-N-181S 5,9 305-325 5 16 0° 7,62 Pb 57-N-122 6,8 275-295 5 16 0° yes “PSM” 5,45 Fe MPC 7N7 2,5 310-335 5 16 0° yes yes Fe 57-N-134S 5,5 415-445 5 16 0° yes yes 5 shots per partial penetr. complete penetr. [m/s] yes/no yes/no panel 3 3 40 yes yes 5 5 5 50 5 7 7 60 12” 18,5 Pb Hunter 35,0 390-410 5 16 0° yes yes 3 AK 74 5,45 Fe hardened 7N6 3,4 890-910 5 - 10 16 0° yes yes 3 7,62 Fe hardened 57-N-231 7,9 710-740 5 - 10 16 0° yes yes 3 5 3 3 4 AK 74 5,45 Fe hardened 7N10 3,4 890-910 5 - 10 16 0° yes yes 3 Dragunov SVD 7,62 Fe 57-N-323S 9,6 820-840 5 - 10 16 0° yes yes 3 AKM 7,62 Fe hardened 57-N-231 7,9 710-740 5 - 10 16 0° yes yes 3 580 ± 10 5 + 0,5 3 MEN, SS 109 10 + 0,5 950 ± 10 10 + 0,5 3 3 3 3 3 3 3 5a FMJ/PB/SCP 9,45 ± 0,1 820 ± 10 10 + 0,5 3 3 3 3 7,62 special 57-BZ-231 7,4 720 - 750 5 - 10 16 0° yes yes 3 Dragunov SVD 7,62 Fe hardened ST-M2 9,6 820-840 5 - 10 16 0° yes yes 3 6a 3 AKM 6 Dragunov SVD 7,62 special 7-BZ-3 10,4 800-835 5 - 10 16 0° yes yes 3 3 FMJ/PB/HC Particularities: • Backing material/ plasticity: • Wet test: • Temperature test: • Min. distance from the edge: • Min. distance from previous shots: List of FSP’s: Weight K4/D4 80 weight [kg] < 10 0,61 2,5 < 20 1,02 2,5 < 10 1,02 2,5 < 20 1,63 2,5 < 10 1,63 2,5 < 20 1,33 5 < 10 1,33 5 < 20 1,63 5 0 65 0 65 0 65 0 65 0 65 0 65 0 65 0 65 HOSDB Body Armour Standards 2007, UK • Test method: • Backing material: • Blade: • Spike: • Stab Energies: P1/B Drop test/ double punch (drop weight 1900 g) Composition of layers of foam and rubber, for shaped armour Roma clay No. 1 Engineered test blade PSDB/P1/B Engineered test spike PSDB/SP/B Blade: Spike: E1 = 24J E2 = 36J E1 = 24J Diameter Weight Level 2 E1 = 33J E2 = 50J E1 = 33J Level 3 E1 = 43J E2 = 65J E1 = 43J [g] [gr] [mm] 1.102 +- 0.02 17.0 +- 0.3 5.385 0.162 +- 0.01 2.5 +- 0.2 2.642 0.237 +- 0.01 3.7 +- 0.2 3.251 0.486 +- 0.02 7.5 +- 0.3 4.064 2.786 +- 0.02 43.0 +- 0.3 7.493 5.0 +- 0.2 3.600 Hardness HRC: Shape: Russian plasticine/gelatine, harder than ROMA (450x400x200 mm) the complete vest front or back panel, vertical immersion or spray, 1 h normal water -40°C and +70°C min. 20 mm min. 5 x caliber, in case of ceramic strike face min. 100 mm 65 height [m] Drop-Test Level 1 0.325 +- 0.01 3 FMs/CB FNB, P 80 If the highest partial velocity exceeds the lowest complete velocity by more than 60m/s, testing should be repeated on a new sample of material. 5 3 7,1 ± 0,1 308 Win. Max. delta No. of down 3 DAG, Special 223 Rem No. of shots required 5 7,62 Must be rifled Rifled or smoth, with or without sabot Firmly clapmed in a rigid framework; no backing within 30 mm of any point of impact Aluminum alloy sheet (AlCu4Mgl) 0.5mm thick, tensile strength 440N/mm², 15cm behind armour 0°; max. yaw 5° Min. 30mm from any clamping point, edge, previous impact, deformation or disturbance No two impact should be made on the same yarn Any projectile which activates/perforates the witness system Velocity for which the probability of penetration of the chosen projectile is exactly 0.5 Mean value of partial and complete penetrations Padding Test 5 .357 Mag 9 Distance 5 Action 4 SK 4 Velocity AKM 9 x 19 7 Bullet- Weight 3 QD-PEP II/S SK 3 Bullet- Code 2a 9 x 19 5 Bullet- Core 3 FMJ/RN/SC; tinned SK 2 Bullet- Tokarev “TT” 3 BulletCaliber Nagan 3 3 Test- [g] 1 2 9mm Luger Stanag FSP 2.786 g/ 43 gr. 7.493mm Bullet FMJ/RN/SC; tinned SK 1 Mil. FSP 1.1 g/ 17 gr. 5.46mm RUSSIA - GOST R 50744-95 Technische Richtlinie March 2008, Germany Class Stanag FSP 1.1g/17 gr 5.385 Barrel for bullets: Barrel for FSP’s: Fixing: Witness system: Striking angle: Distances: Complete penetration: V50 definition: V50 calculation: 65 P1/B highest single penetration [mm] 30 +- 2 see drawings in the standard • No. of attacks: Blade: 30x E1 at 0°; 10x E2 at 0° Angle attack at 45° only at potential weak areas Spike: 10x E1 at 0° • Max. penetration into backing: Blade: 7mm for E1 and 20mm for E2 (1x up to 30 mm perm.) Spike: 1penetration out of 10 strikes permitted • Measurement of penetration: blade protruding length; width of the cut; blade into clay • Min distances: 50 mm from the edges and any previous attack • Particularities: Blade only and blade + spike protection permitted, spike only not permitted NIJ Standard 0115.00, USA S1 • Test method: • Backing material: Ammunition Inspection Level Test-Bullet Bullet weight [g] Distance Bullet velocity [m/s] 0° 65° 0° / contact shot 0° 0° 0° Class V50 test Padding down TestBullet BulletProducer BulletWeight [g] [gr.] BulletVelocity [m/s] [ft/s] Max. BFD Norinco 5.6 Norinco 5.6 optional +20°C 1 22 Long rifle L/RN 2,6 ± 0,1 Winchester 10 + 0,5 360 ± 10 +20°C +20°C +40°C climat -20°C 3 3 3 3 3 1 +70°C 3+1 yes 7.62 x 25 2 7.62 x 25 9mm Luger FMJ/RN/SC; tinned 8,0 ± 0,1 DAG, DM 41 5 + 0,5 360 ± 10 3+1 3 3 3 3 3 yes yes 3 9mm Luger FMJ/RN/SC; tinned 8,0 ± 0,1 DAG, DM 41 5 + 0,5 415 ± 10 3+1 3 3 3 3 3 yes yes .357 Mag FMJ/CB/SC 10,2 ±0,1 Geco 5 + 0,5 430 ± 10 3 3 3 3 3 .44 Rem. Mag FMJ/FN/SC 15,6 ± 0,1 Speer 5 + 0,5 440 ± 10 3 3 3 3 .357 Mag FMs/CB 7,1 ± 0,1 DAG, Special 5 + 0,5 580 ± 10 3 3 3 3 3 6 7,62 x 39 FMJ/PB/FeC 8,0 ± 0,1 PS 10 + 0,5 720 ± 10 3 3 3 3 3 223 Rem FMJ/PB/SCP 4,0 ± 0,1 MEN, SS 109 10 + 0,5 950 ± 10 3 3 3 3 3 308 Win. FMJ/PB/SC 9,55 ± 0,1 MEN, DM 111 10 + 0,5 830 ± 10 3 3 3 3 7,62 x 39 FMJ/PB/HCI 7,7 ± 0,1 BZ 10 + 0,5 740 ± 10 3 3 3 3 3 9 308 Win. FMJ/PB/HC 9,45 ± 0,1 FNB, P 80 10 + 0,5 820 ± 10 3 3 3 3 3 10 7,62 x 54 R FMJ/PB/HCI 10,4 ± 0,1 B32 10 + 0,5 860 ± 10 3 3 3 3 308 Win. FMJ/PB/WC 8,4 ± 0,1 Nammo, AP 8 10 + 0,5 930 ± 10 3 3 3 3 308 Win. FMJ/PB/WC 12,7 ± 0,1 SWISS P AP 10 + 0,5 810 ± 10 3 3 3 3 3 13 50 Browning FMJ/PB/HC 43,0 ± 0,5 SWISS P Penetrator 930 ± 20 3 3 3 3 3 14 14,5 x 114 FMJ/PB/HCI 63,4 ± 0,5 B32 911 ± 20 3 3 3 3 3 0° 3x no 5 2 430 +- 10 25 no 5 2 no 5 2 no 5 7.62 x 25 7.62 x 25 5.6 no 5 Particularities: • Backing material/ plasticity: • Back face deformation: • Wet test: • Edge test: • Min. distance from the edge: • Min. distance from previous shots: • Presssed shot: • Volume: Weible clay 20mm ± 2mm (1.04 kg sphere from 2m height) Concealable vest: 1 x investigated plasticity value + 22m (constant) Tactical vest: 1 x investigated plasticity value; pressed shot 1 x investigated plasticity value + 22mm (constant) No wet test required For Level 1,2 and 3 one shot 30mm +- 5mm from the edge is required 75 mm (expect edge shot, 30mm from the edge, 75 from the corner) 75 mm 100 ± 5 N force, total mass 50 ± 1kg = (0,134 x plasticity - 1,13) x 70 Joule, measured if back face signature is ≥ 20mm not for pressed shot 7.62 x 25 1 7.62 x 39 E1 = 33J E2 = 50J Level 3 E1 = 43J E2 = 65J P1/A 2 25 0° 3x • No. of attacks: • Max. penetration into backing: • Measurement of penetration: • Min distances: • Particularities: 4x E1 at 0°; 4x E2 at 0°; 4x E1 at 45° with each blade and or the spike 7mm for E1 and 20mm for E2 blade/spike protruding length; witness paper 51 mm from the edges and any previous attack Blade/ spike only and Blade + spike protection permitted 30° 2x Norinco 5.6 430 +- 10 25 0° 3x 30° 2x Norinco 5.6 505 - 520 25 FMJ HC 6 E2 = 36J Level 2 2 505 - 520 FMJ HC 5 0° 3x 30° 2x Norinco E1 = 24J 2 30° 2x 3 12 25 3 11 4 3 8 300 +- 10 FMJ SC 3 7 Blade and Spike: No. of tests FMJ SC 3 5 Padding down yes/no No. of shots per panel [mm] Angle Test [° Nato] FMJ SC yes 2 4 Engineered test blades PSDB/P1/A and PSDB/S1/G Engineered test spike Level 1 No. of shots performed under the following conditions Bullet producer • Blades: • Spike: • Stab Energies: CHINA VPAM 2006 Drop test/ double punch (drop weight 1900 g) Composition of layers of foam and rubber 0° 3x 30° 2x Norinco 7.9 710 - 725 25 0° 1x FMJ HC LEGEND Particularities: • Shoting distances: • Backing material/ plasticity: • Wet test: Shot 1, 2 and 3 from 5m; shot 4 from 7m; shot 5 from 10m Clay (Chinese type) Yes, 30 min. immersion, 5 min dripping AP CB FMJ FMSJ FMSJ FN FSP armour piercing coned bullet full metal jacket full metal steel jacket brass flat nose flat nose fragment simulating projectile HC steel hard core HCI steel hard core, incendiary JHP jacketed hollow point LRHV long rifle high velocity LRN lead round nose Mag. Magnum P penetrator PB pointed bullet RN round nose SC soft core SCP lead soft core with steel penetrator SWC semi-wadcutter (TC), WC tungsten carbide

Open the catalog to page 1All TEIJIN ARAMID BV catalogs and brochures

-

Leaflet-Marine

2 Pages

-

Ballistic Material Handbook

11 Pages

-

Twaron-product-brochure

7 Pages

-

Optical-fiber-cables-leaflet

2 Pages

-

Leaflet-Twaron-Tape_final-LR

2 Pages

-

Engineering-Plastics-leaflet

2 Pages

-

Leaflet-special-paper-v2

2 Pages

-

Leaflet-Staple-fibre_Engels

2 Pages

-

Leaflet-Twaron-Black_lowres

2 Pages

Archived catalogs

-

Properties-of-Twaron

1 Pages