Website:

Techni

Website:

Techni

Catalog excerpts

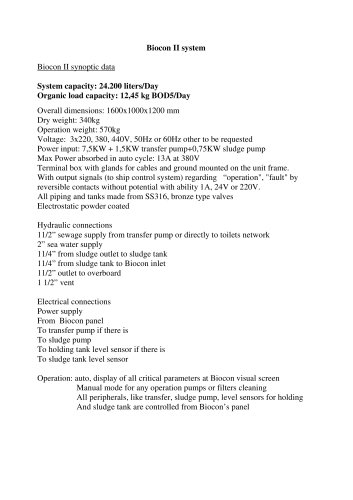

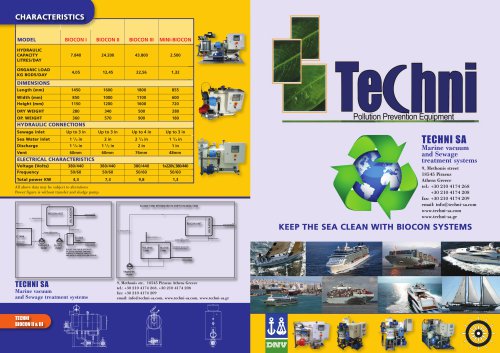

Biocon II system Biocon II synoptic data System capacity: 24.200 liters/Day Organic load capacity: 12,45 kg BOD5/Day Overall dimensions: 1600x1000x1200 mm Dry weight: 340kg Operation weight: 570kg Voltage: 3x220, 380, 440V, 50Hz or 60Hz other to be requested Power input: 7,5KW + 1,5KW transfer pump+0,75KW sludge pump Max Power absorbed in auto cycle: 13A at 380V Terminal box with glands for cables and ground mounted on the unit frame. With output signals (to ship control system) regarding “operation", "fault" by reversible contacts without potential with ability 1A, 24V or 220V. All piping and tanks made from SS316, bronze type valves Electrostatic powder coated Hydraulic connections 11/2” sewage supply from transfer pump or directly to toilets network 2” sea water supply 11/4” from sludge outlet to sludge tank 11/4” from sludge tank to Biocon inlet 11/2” outlet to overboard 1 1/2” vent Electrical connections Power supply From Biocon panel To transfer pump if there is To sludge pump To holding tank level sensor if there is To sludge tank level sensor Operation: auto, display of all critical parameters at Biocon visual screen Manual mode for any operation pumps or filters cleaning All peripherals, like transfer, sludge pump, level sensors for holding And sludge tank are controlled from Bio

Open the catalog to page 1

CONFIGURATION LAYOUT When holding tank level sensor is activated, auto cycle begins, A certain quantity of sewage enters in Biocon unit Microfilter unit expels sludge to the sludge tank during the process When in Sludge tank level exceeds high level, then sludge pump recirculates The upper part of the watered sludge to Biocon unit again Sludge tank may be ship’supply or may come integrated with Biocon unit.

Open the catalog to page 2

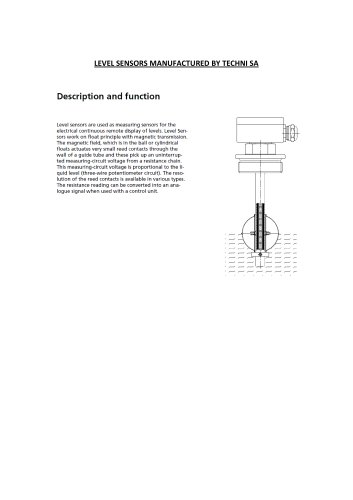

LEVEL SENSOR Date Ed. Appr Original Project template with IEC identifier structure EFFLUENT OUTLET WATER SOLENOID VALVE ONLY WHEN STP IS BELOW SEA LEVEL EPLAN Software & Service GmbH & Co. KG TRANSFER PUMP TO BIOCON RECYCLING TO BIOCON INLET SEWAGE TREATMENT SYSTEM BIOCON II SLUDGE TANK SHIP'S SUPPLY BACKWASH TO SLUDGE TANK CLEAN EFFLUENT LEVEL SENSOR FILTER OUTLET FILTER BYPASS ITEMS IN DASH LINE IS BIOCON II STP HYDRAULIC INSTALLATION WITH SEPARATE SLUDGE TANK INSTALLATION WITH SEPARATE SLUDGE TANK AND SEWAGE SUPPLY FROM HOLDING TANK INTERNATIONAL CONNECTION SEWAGE SUPPLY TO BIOCON II...

Open the catalog to page 3

1. SEWAGE INLET SUPPLY 3’’ 2. FILTER MOTOR 3.-(12) FILTER INLET MANOMETER 4. FILTER PRESSOSTAT (2,5 BARS) 6. FILTER BACKWASH VALVE NPT 1 1/4’’ 7. LER AUTLET MANOMETER 8. FILTER BODY 9. EXPANSION TANK 8L 10.PRESSURE REGULATING VALVE (2,4)BARS 11.FILTER OUTLET LINE 12.-(3) INFLOW MANOMETER 14.INLET FILTER VALVE 15.RECYCLING PUMP 16.DISCHARGE PUMP 17.OUTLET FILTER VALVE 19.FLANGE-DISCHARGE OUTBOARD FLANGE 1

Open the catalog to page 4

20.FILTER BYPASS VALVE 21.FILTER AND LINE DRAINAGE VALVE 22.BIOCON’S FRAME 23.FILTER BYPASS LINE 24.FILTER’S FRAME 25.BIOCON’S TREATMENT TANK 26.MACERATOR 27.BIOCON’S VENT 11/2” 28.OXYDATION AIR INLET 29.BIOCON LEVEL SENSOR 30.THREE WAY VALVE 31.INSPECTION DOOR 32.CHLORIDE INJECTION INLET 33.MAIN ELECTRICAL CABINET 34.CHLORIDE DOSAGE PUMP 35.CHLORIDE TANK 36.SEA WATER PUMP 37.SEA WATER PUMP INLET

Open the catalog to page 5All Techni catalogs and brochures

-

BIOCON

2 Pages

-

LEVEL SENSORS

3 Pages

-

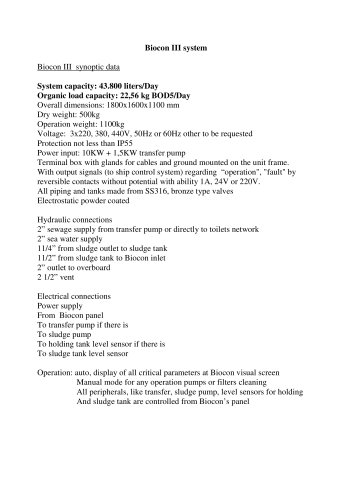

BIOCON IΙΙ

7 Pages

-

BIOCON I

5 Pages