Website:

Spirit Yachts

Website:

Spirit Yachts

Catalog excerpts

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 1

RING FRAMES The process begins with a 1:1 scale drawing placed on a flat laminating table. Irons are then screwed down following the line of the frame. The correct amount of laminates allocated to the size of yacht are then rolled with glue and clamped into the irons to form the correct shapes. Once these have set, they are machined to the correct thickness and assembled with knees joining the beam to the ring frame. The assembled frame is then cleaned, water lines and buttock lines are transferred to the frame and the edge is bevelled to the correct angle. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 2

ASSEMBLING FRAMES The frames are then stood upright and upside down in a softwood strongback, set at the correct distance apart from each other to form the shape of the yacht. Once they are levelled using a theodolite, the stem and stern bulkheads are glued in place followed by the laminated back bone. The assembly is then cleaned, the surfboard cheeks are glued on and the stem is planed to the correct shape. This process is finished with the beamshelf being cut into the frames, shaped and glued in. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 3

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 4

With the frames assembled in place, the rudder blocking, stern tube blocking and engine beds are glued in place. The structure is then planed and pole sanded to make it fair and the frames are taped to be kept protected. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 5

DOUGLAS FIR PLANKING The first two planks each side are glued on in the middle of the span, finding a fair line extending across the length of the yacht. The planks are screwed on to hold the shape and the screws are then removed as the process continues. The planking process continues working above and below the first 2 planks until the entire yacht is covered. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 6

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 7

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 8

HULL VENEERING The next stage in the building process is the hull veneering. To begin the screw holes left from the planking stage are filled and the whole surface is sanded and sealed with epoxy to create a smooth surface. 2 or more layers (depending on the size of the yacht) of diagonal 3mm Khaya or Sapele veneer are then fitted. It begins with a dry fit of the veener to get the correct lengths and curvature before the glue is then rolled onto the hull. Further glue is applied to the veneer itself which is placed onto the hull and held in place using the minimum amount of plastic staples...

Open the catalog to page 9

A vacuum bag is then used to apply pressure to hold the veneer into place until the glue is set. Each layer is then sanded before the next layer is applied. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 10

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 11

GLASS Two or more layers of biaxial glass and a twill layer on the topside are then applied and consolidated using vacuum pressure. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 12

CARBON On larger yachts, carbon is also used for local high load stiffening to reduce the size of the structure therefore reducing weight and increasing interior volume SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 13

ROLLOVER With the hull complete, it is rolled over to begin the interior fitout. Depending on the size of the yacht this will usually require the hull to be taken outside of the yard and rolled over using cranes. SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 14

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 15

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 16

FINISHED HULL With the hull back inside the yard the correct side up, the hull is now ready to be fitted with a beatiful interior SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 17

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 18

SPIRIT HULL CONSTRUCTION PROCESS

Open the catalog to page 19All Spirit Yachts catalogs and brochures

-

Spirit Yachts - Superyacht Range

45 Pages

-

Spirit P70

14 Pages

-

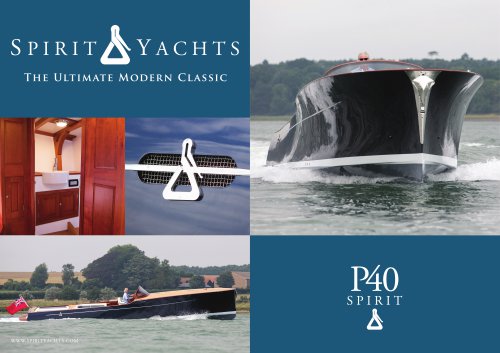

Spirit P40

2 Pages

-

Spirit SY111

23 Pages

-

Spirit SY100

10 Pages

-

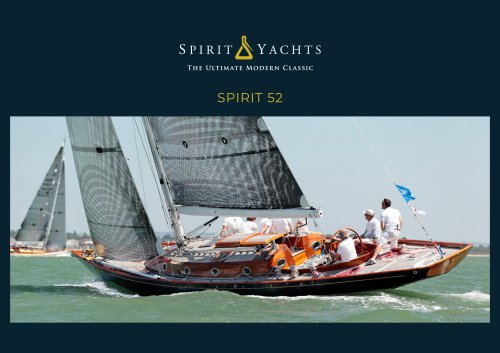

Spirit R52

11 Pages

-

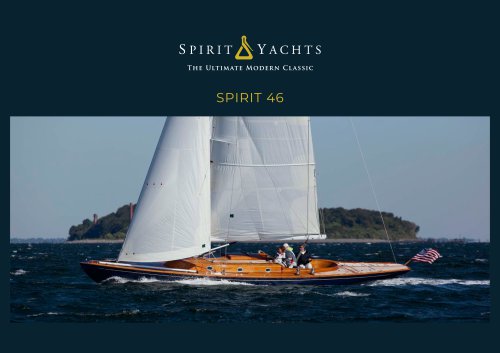

Spirit R46

12 Pages

-

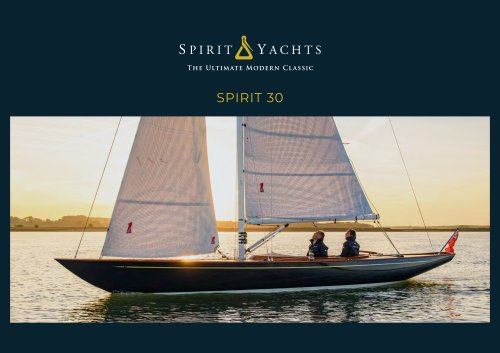

Spirit R30

15 Pages

-

Spirit C72

15 Pages

-

Spirit C65

15 Pages

-

Spirit C50

16 Pages

-

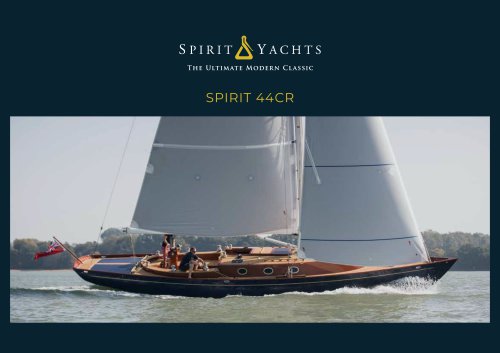

Spirit C44

15 Pages