Catalog excerpts

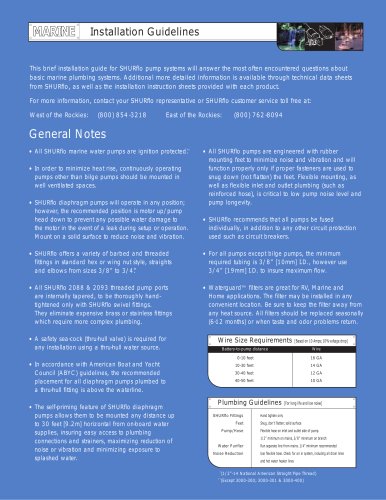

MARINE Installation Guidelines This brief installation guide for SHURflo pump systems will answer the most often encountered questions about basic marine plumbing systems. Additional more detailed information is available through technical data sheets from SHURflo, as well as the installation instruction sheets provided with each product. For more information, contact your SHURflo representative or SHURflo customer service toll free at: MARINE West of the Rockies: (800) 854-3218 East of the Rockies: (800) 762-8094 General Notes †† • All SHURflo marine water pumps are ignition protected. • In order to minimize heat rise, continuously operating pumps other than bilge pumps should be mounted in well ventilated spaces. MARINE • SHURflo diaphragm pumps will operate in any position; however, the recommended position is motor up/pump head down to prevent any possible water damage to the motor in the event of a leak during setup or operation. Mount on a solid surface to reduce noise and vibration. MARINE • All SHURflo pumps are engineered with rubber mounting feet to minimize noise and vibration and will function properly only if proper fasteners are used to snug down (not flatten) the feet. Flexible mounting, as well as flexible inlet and outlet plumbing (such as reinforced hose), is critical to low pump noise level and pump longevity. • SHURflo recommends that all pumps be fused individually, in addition to any other circuit protection used such as circuit breakers. • SHURflo offers a variety of barbed and threaded fittings in standard hex or wing nut style, straights and elbows from sizes 3/8” to 3/4. ” • For all pumps except bilge pumps, the minimum required tubing is 3/8” [10mm] I.D., however use 3/4” [19mm] I.D. to insure maximum flow. • All SHURflo 2088 & 2093 threaded pump ports are internally tapered, to be thoroughly handtightened only with SHURflo swivel fittings. They eliminate expensive brass or stainless fittings which require more complex plumbing. • Waterguard™ filters are great for RV, Marine and Home applications. The filter may be installed in any convenient location. Be sure to keep the filter away from any heat source. All filters should be replaced seasonally (6-12 months) or when taste and odor problems return. MARINE • A safety sea-cock (thru-hull valve) is required for any installation using a thru-hull water source. Wire Size Requirements [Based on 10 Amps; 10% voltage drop] Battery-to-pump distance Wire 0-10 feet • The self-priming feature of SHURflo diaphragm pumps allows them to be mounted any distance up to 30 feet [9.2m] horizontal from on-board water supplies, insuring easy access to plumbing connections and strainers, maximizing reduction of noise or vibration and minimizing exposure to splashed water. MARINE 14 GA 30-40 feet 12 GA 40-50 feet MARINE 16 GA 10-30 feet • In accordance with American Boat and Yacht Council (ABYC) guidelines, the recommended placement for all diaphragm pumps plumbed to a thru-hull fitting is above the waterline. 10 GA Plumbing Guidelines [For long life and low noise] SHURflo Fittings Feet Pump/Hose Hand tighten only Snug, don’t flatten; solid surface Flexible hose on inlet and outlet side of pump. 1/2” minimum on mains, 3/8” minimum on branch Water Purifier Noise Reduction Run separate line from mains. 1/4” minimum recommended Use flexible hose. Check for air in system, including all drain lines and hot water heater lines † (1/2”-14 National American Straight Pipe Thread) †† (Except 3000-300; 3000-301 & 3000-400)

Open the catalog to page 1

MARINE Installation Guidelines 1500/1800 Bilge Pumps Recommended mounting: attach base to hull or stringer using stainless steel screws. Snap pump into base. By using the base, the pump may be easily removed for cleaning. MARINE Mounting Optional mounting: Base may be removed and screws placed through the two holes located on each side of the pump (1500 & 1800 series only). CAUTION: Care must be taken not to drive the screws through the hull. Be sure pump is mounted on a flat surface, as low as possible in the bilge. Attach 1-1/8” [28mm] I.D. smooth bore hose. Use of a smooth bore hose will...

Open the catalog to page 2

Bait Sentry™ Magnetic Impeller Pumps Blaster nozzle Bait / Livewell For livewell systems using the Bait Sentry™ SHURflo recommends , marine approved reinforced hose. Always use double stainless steel clamps for plumbing below the water line. A sea-cock valve must be installed between the pump and the thru-hull fitting. Pump impeller must be below the water line. To prevent an airlock situation, do not allow outlet tubing to sag between pump and tank. Discharge port on pump must be pointed up toward tank, not down towards keel. Flow adjust valve Blaster Washdown Pump Bait Sentry Guardian Raw...

Open the catalog to page 3All Shurflo catalogs and brochures

-

Fill Valve 3/4" 330-010/021

1 Pages

-

380 BILGE PUMP 355-020-00/10

2 Pages

-

Extreme SS 5.7 12v 5901-0201

2 Pages

-

BILGE PUMP 355-100-00

2 Pages

-

YellowTail Blower 277-4100

2 Pages

-

Faucet_replacement

1 Pages

-

YellowTail Blower 277-3100

2 Pages

Archived catalogs

-

Marine Product Catalog

16 Pages