Catalog excerpts

® FAST® Process w w w. m a r i n e fa s t . c o m S M I T H & L OV E L E S S I N C . Design Guidelines — Building FAST® Systems Into Ships’ Tanks Scope These design guidelines are intended to assist naval architects and engineers in determining the feasibility of and the requirements for building FAST® sewage treatment systems into ship’s tanks. The guidelines are general in nature, are subject to change without notice and shall not be used for design without prior review and written approval by FAST® Systems specific as to each case. Secondary Treatment 1. Based upon a 30 day average, EPA defines secondary treatment as removal of 85% of applied BOD5 and TSS and effluent containing an average of not more than 30 mg/l of either parameter (45 mg/l average during a 7 day period). 2. In industrial applications where diluting water might be added to the water for process purposes, the required effluent parameters must be adjusted for the dilution. That is, if 2 gallons of seawater are added to 1 gallon of wastewater to produce chlorine or for any other reason, the diluted effluent must contain not more than 10 mg/l BOD5 and TSS. 3. Achieving this performance requires separation of residual sludge from the effluent. General The FAST® process is unique in that its application is relatively independent of tank shape. Therefore, the process can usually be built into ship’s tanks. For most marine applications, the process requires two tanks: 1. A Media Tank to convert raw sewage into water and 2. A Wet Well to provide chlorine contact volume and/or to act as a sump for automatic control of discharge pumps. The Media Tank is sized by the organic load and the Wet well is sized by the hydraulic load. The sizing and other requirements for these tanks depend upon: Sludge Storage 1. Residual sludge is a byproduct of the FAST® process, as it is of any process capable of removing BOD5 and TSS. 2. 1. 2. 3. Whether or not long term sludge storage will be required and the length of the storage period required. The sludge comprises non-biodegradable materials and those biodegradable materials which have not been fully oxidized to CO2 and water. Process tanks of practical size will produce a residual sludge and that sludge can be separated from the effluent and stored for separate disposal. The effluent standard to be met. 3. The types of domestic wastewater to be treated. 4. The number of persons to be served. 4. A system designed to meet minimum USCG and IMO requirements does not require long term sludge storage. 5. Whether vacuum or conventional toilets will be employed. 5. Many FAST® units incorporate internal sludge storage for periods ranging from 90 days to one year. Such long storage periods can be useful to vessels which never leave controlled waters. 6. If the vessel does leave controlled waters from time to time, the stored sludge can be discharged at sea. 6. Whether chlorine or UV disinfection will be employed. USCG and IMO Requirements 1. These certifications are based upon a ten day test. 2. 3. The regulations do not require performance testing of the individual system after installation and the question of performance after the ten day period is not addressed. These regulations also incorporate a loophole which permits a system to meet the requirements using dilution rather than removal of BOD5 and TSS. Types of Domestic Wastewater to be Treated 1. Marine regulations define sewage as human waste and the water which transports that waste (black water). Gray water and ground food waste from the galley are not included in that definition. E-mail: solutions@sciencofast.com • Phone: continued on next page 314.645.6540 • FAX: 314.645.6131 FA

Open the catalog to page 1

FAST® Page 2 continued from front side If one or more other sources of domestic sewage are added to the black water, then the organic loading per capita will be correspondingly increased. This is illustrated by the service factors shown in the table below: 1. Service Factor The service Type of Waste Black Water 1.00 factor for all Personal Wash Water 0.42 black water Laundry 0.41 and gray Dishwashing 0.33 water is 1.00 Garbage Disposal 1.21 + 0.42 + 0.31 +0.33 = 2.06. This means that the organic loading associated with the black and gray water from 100 persons corresponds to the loading...

Open the catalog to page 2

FAST® Page 3 continued from p.2 5. Wet Well Reqs. – Cl Disinfection, Conventional Toilets 1. Chlorine contact time should be not less than 15 minutes at peak flow. This is 4.0 times average for most marine applications. 2. Expected flow with conventional toilets would be 200 persons X 46 gpcd = 9,200 gpd and peak flow would be 9,200 ÷ 1,440 minutes/day X 4.0 = 25.6 gpm. Minimum contact volume would be 25.6 X 15 minutes = 383 gallons. Sizing the Wet Well at 150% of these volumes produces a tank of 77 X 150% = 116 gallons for conventional toilets and 59 X 150% = 89 gallons for vacuum toilets....

Open the catalog to page 3

FAST® Page 3 continued from front side ® Contact us via e-mail at solutions@sciencofast.com or through project inquiry at our website 8229 Brentwood Industrial Drive • Brentwood, MO 63144 • Phone: 314.645.6540 • Fax: 314.645.6131 S M I T H & L OV E L E S S I N C. FAST® SYSTEMS

Open the catalog to page 4All Scienco/FAST catalogs and brochures

-

Water Treatment Solutions

6 Pages

-

DV-Series Reference

2 Pages

-

DESIGN GUIDELINES

4 Pages

-

MarineFAST® Brochure

6 Pages

-

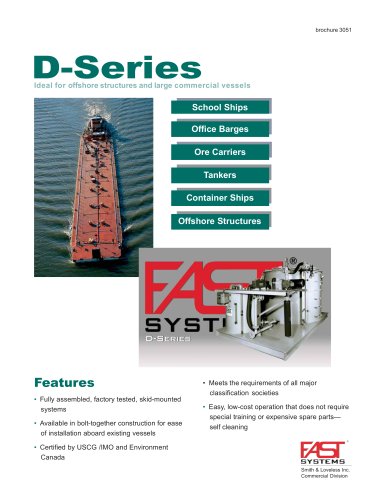

D-Series sewage treatment

8 Pages

-

LX-Series sewage treatment

4 Pages