Catalog excerpts

Biosolids Management System Standard Specification Unless otherwise specified, design and construction of MarineFAST® Biosolids Management Systems (BMS) shall follow these guidelines. The unit shall provide aerobic digestion, dewatering, concentration and long term storage of secondary sludge taken from FAST® marine sewage treatment systems that are designed to meet MEPC.159(55) or other secondary treatment requirements. All sewage and sewage sludge will be contained in tanks and piping. Personnel shall not come into contact with sewage or sewage sludge during operation of the BMS. Operation will be automatic and will not require intervention by vessel personnel. Process The sludge will be aerobically digested in the BMS unit. A regenerative turbine blower will transfer oxygen into the tank contents and provide mixing and circulation of the tank contents. The blower will be cycled on and off in order to alternate aerobic and anoxic conditions within the tank. This will stabilize the pH and permit efficient digestion of the sludge. Sludge from the bottom of the FAST unit media tank will be transferred automatically to the BMS unit. 2. Aeration will transfer oxygen into the tank contents and will also provide circulation so that the process will be completely mixed. 3. Rising water level will actuate a float switch and begin an automatic sequence to separate the digested sludge from excess water. 4. The blower will be shut off to allow the sludge to settle and excess water to rise. 5. A power operated valve will allow the excess water to drain to the supernatant pump wet well. 6. The supernatant pump will automatically return the water to the FAST unit. 7. When the liquid level drops, a second float switch will cause the drain valve to close and the blower will re‐ start. 8. When it is time to empty the accumulated sludge in the BMS tank, it can be discharged to a larger tank, to an offshore supply vessel, to an incinerator or to whatever destination best fits the operation of the vessel or platform. 9. After all connections are made, the pumpout process can be started. When the liquid level drops in the tank, the sludge pump will shut off automatically. 10. If the operator desires to strip the tank before resuming automatic operation, he can do this manually. It is important to note the difference here between anoxic and anaerobic conditions. “Anoxic” simply means that the dissolved oxygen in the tank contents will be depleted. At no time will the process create anaerobic conditions resulting in formation of methane or corrosive acids. Settled sludge will be retained for eventual removal and excess water will be returned to the FAST unit for treatment and legal discharge to the sea.

Open the catalog to page 1

Because of the long detention time in the tank (typically six month’s storage), the BMS water temperature will approach the ambient temperature in the space and selection of the space will be an important factor in successful operation. So, it will be best if the BMS is not located in a 50° C. machinery space. Both the FAST unit and the BMS unit will be fitted with pumps to permit remote installation. Standard Construction All equipment shall be in accordance with US Coast Guard requirements for inspected vessels. This includes but is not ...

Open the catalog to page 2

temperature, also suitable for operation at 50 C. ambient with service factor of 1.00. Motor starters, control panels and junction boxes shall have NEMA 4/4X or IP 55 enclosures as applicable. The unit shall be designed for long service life processing seawater sewage sludge in heavy marine or offshore service. Testing The Media Tank shall be hydrostatically tested per 33 CFR Part 159 and no leaks are permitted. The blower, pumps and power operated valve shall be operated to confirm proper operation in both automatic and manual modes. Piping All customer ...

Open the catalog to page 3All Scienco/FAST catalogs and brochures

-

Water Treatment Solutions

6 Pages

-

DV-Series Reference

2 Pages

-

DESIGN GUIDELINES

4 Pages

-

MarineFAST® Brochure

6 Pages

-

FAST Conversions

4 Pages

-

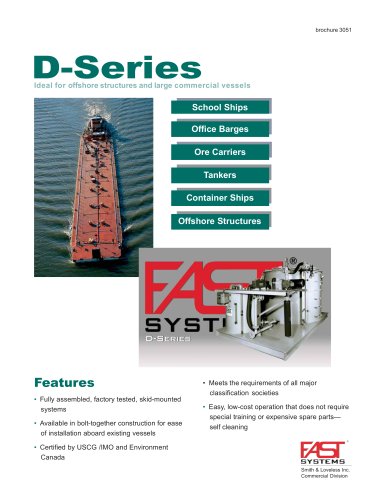

D-Series sewage treatment

8 Pages

-

LX-Series sewage treatment

4 Pages