Catalog excerpts

PSI-75 Primer Product description PSI-75 Primer is a single-component, synthetic rubber-based solution used as a primer for PSI polysulfide and silicone sealants on porous and non-porous substrates. Basic uses PSI-75 Primer promotes adhesion of PSI polysulfide sealants and some PSI silicone sealants to metal, concrete, masonry, glass, ceramics and certain plastics. It is the required primer for use with polysulfide sealants for water immersion applications. Application limitations cleaned with xylene or other suitable solvent. When using flammable solvents, consult manufacturer's MSDS for safety precautions. Coverage Chart Joint Depth 1/4” Lineal Feet 300 3/8” 225 1/2” 150 Shelf life: One year from date of shipment when stored in original, unopened container at temperatures between 40 and 80°F (4 to 27°C). Technical services • If sealant cannot be installed within 8 hours, reprime. • Keep cans tightly closed when not in use as primer will deteriorate when exposed to moisture. • Do not apply over wet or damp substrates. • Do not apply primer to backer rod to prevent three-sided adhesion. Packaging Available in pint (473 ml) cans. Application PSI provides field service, performance data, specification assistance and use evaluations. Adhesion testing by PSI: This program is intended to eliminate potential field-application problems by pre-testing the adhesion of PSI's construction sealants on samples of building materials submitted by the customer. The tests will aid in determining the proper surface preparation method, effective solvents for cleaning and whether priming is necessary to achieve optimum adhesion. Following this procedure will remove many of the variables that affect field success. Preparation: Surfaces to which primer is Test samples should be identified as to applied must be clean, dry and free of laitance, loose aggregate, grease, oil, wax, corApplication Properties* rosion, rust, waterproofing compounds, mastic compounds, and previouslyConsistency Light amber liquid applied sealants. Specific gravity 1.07 Density 6.84 lb/gal Application: Apply primer by brush, Dry time from priming to sealant roller, or spray in a thick, continuous film. application, dependent on ambient Avoid pools, runs and drips. Allow primer temperature and relative humidity Approx. 1 hour to become dry to the touch (approximately Open time 8 hours 1 hour) before installing sealant. If primer 782 gm/L is allowed to dry over 8 hours, repriming VOC content Flash point 45°F (7°C) is necessary. Non-volatile content 20 to 25% Cleanup: Equipment can be * Typical properties are for information only, not for purposes of specification.

Open the catalog to page 1

manufacturer, origin, designed use, building project, person and firm originating the request. Appropriate sketches of drawings showing the intended use can be helpful. They should be sent to the attention of PSI's Technical Director. Jobsite testing of substrates: A field test can be performed by applying several feet ot the sealant to a representative joint and letting it reach full cure. Make a cut in the cured sealant across the joint the entire depth of the sealant. Make two vertical cuts several inches long, paralleling the sides of the joint as closely as possible and extending down...

Open the catalog to page 2All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

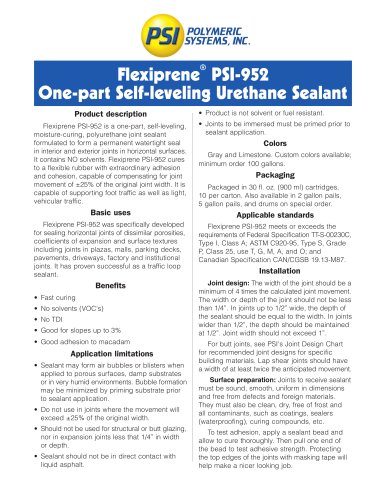

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

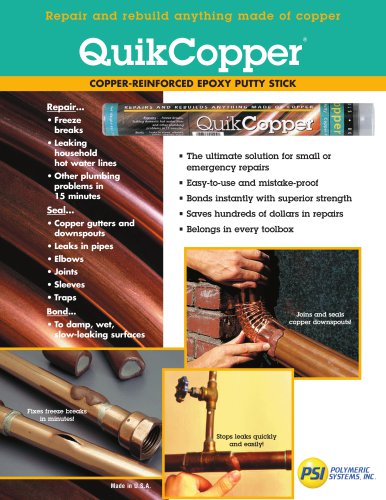

QuikCopper

2 Pages

-

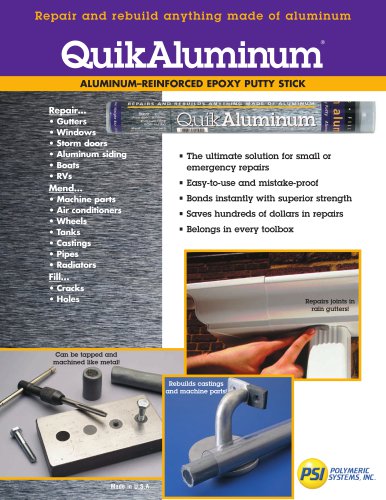

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

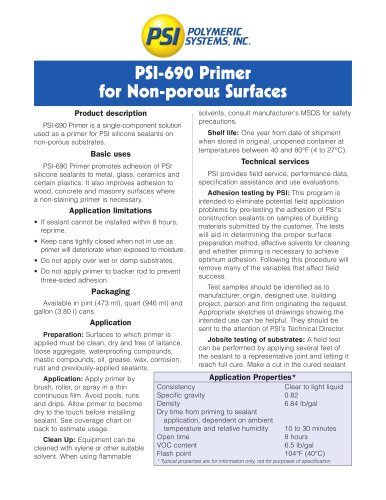

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

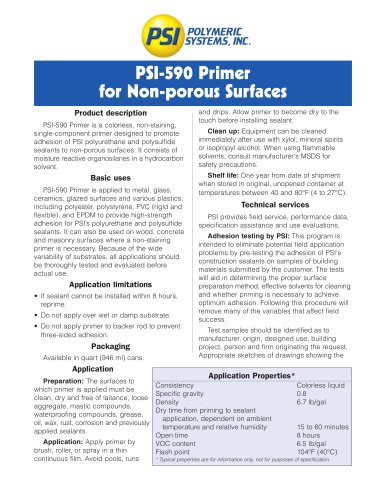

PSI-590TDS(1004-EM07)

2 Pages

-

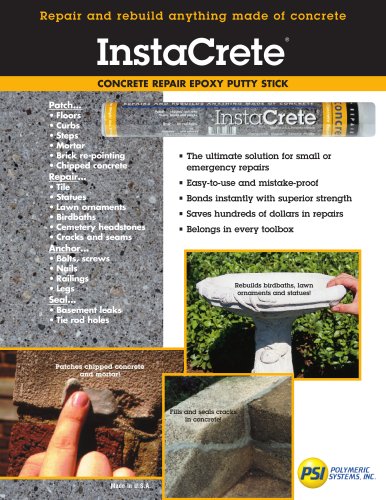

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

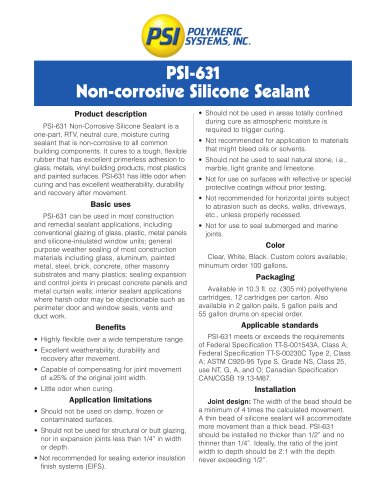

PSI-631TDS(7003-EM07)

3 Pages

-

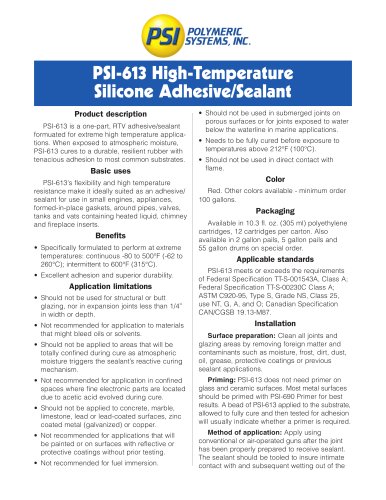

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

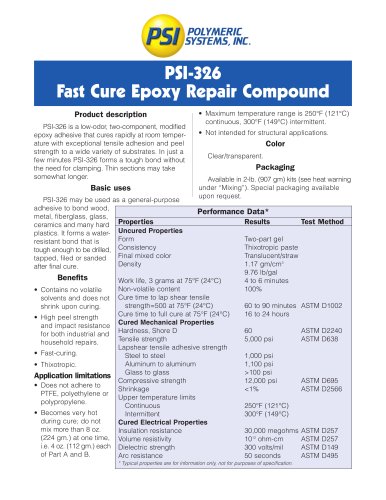

PSI-326 TDS(2008-1009)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages