Catalog excerpts

PSI-691 Primer for Porous Surfaces Product description PSI-691 Primer is a single-component, high solids, clear amber solution used as primer for PSI silicone sealants on porous substrates. Basic uses PSI-691 Primer is applied to concrete, masonry, marble, and wood substrates to provide high strength adhesion for PSI's silicone sealants. It is also used to firm up friable or sandy concrete, brick or stone prior to caulking. Application limitations • Do not apply over wet or damp substrates. • Could stain marble or stone. Testing prior to project application is recommended. • Must be free of pools, runs and drips. • Do not apply primer to backer rod to prevent three-sided adhesion. Packaging Available in pint (473 ml), quart (946 ml) and gallon (3.80 l) cans. Application Preparation: The surfaces to which primer is applied must be clean, dry and free of laitance, loose aggregate, waterproofing compounds, mastic compounds, oil, grease, wax, corrosion, rust and previously-applied sealants. Application: Apply primer by brush, roller, or spray in a thin continuous film. Avoid pools, runs and drips. Allow primer to become dry to the touch before installing sealant. Clean Up: Equipment should be cleaned with xylene or other suitable solvent. When using flammable solvents, consult manufacturer's MSDS for safety precautions. Shelf life: One year from date of shipment when stored in original, unopened container at temperatures between 40 and 80°F (4 to 27°C). Technical services PSI provides field service, performance data, specification assistance and use evaluations. Adhesion testing by PSI: This program is intended to eliminate potential field application problems by pre-testing the adhesion of PSI's construction sealants on samples of building materials submitted by the customer. The tests will aid in determining the proper surface preparation method, effective solvents for cleaning and whether priming is necessary to achieve optimum adhesion. Following this procedure will remove many of the variables that affect field success. Test samples should be identified as to manufacturer, origin, designed use, building project, person and firm originating the request. Appropriate sketches of drawings showing the intended use can be helpful. They should be sent to the attention of PSI's Technical Director. Jobsite testing of substrates: A field test can be performed by applying several feet of the sealant to a representative joint and letting it reach full cure. Make a cut in the cured sealant across the joint the entire depth of the sealant. Make two vertical cuts several inches long, Application Properties* Consistency Specific gravity Density Dry time from priming to sealant application, dependent on ambient temperature and relative humidity Open time VOC content Flash point Clear to yellow liquid 1.02 8.5 lb/gal 30 to 60 minutes 8 hours 4.25 lb/gal 82° F (28° C) * Typical properties are for information only, not for purposes of specification.

Open the catalog to page 1

paralleling the sides of the joint as closely as possible and extending down from the cross cut. Grasp the free length of sealant and pull at a 90° angle to determine if a good bond has developed. With good adhesion, the sealant will usually tear cohesively or be difficult to remove from the surface. Availability and cost Polymeric Systems, Inc., is a part of Whitford Worldwide. For more information, please contact Polymeric Systems or Whitford Plastics Ltd. at: Polymeric Systems, Inc. 47 Park Avenue Elverson, PA, USA 19520 800-CAULK IT (800-228-5548) Tel: [1] 610-286-2500 Email:...

Open the catalog to page 2All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

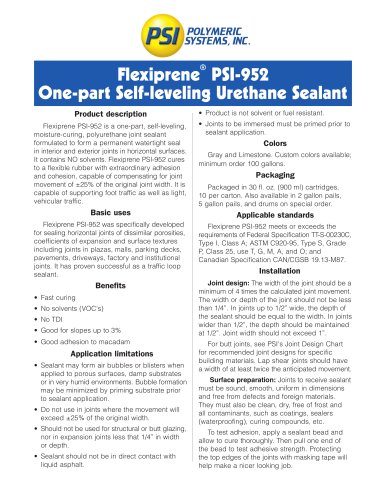

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

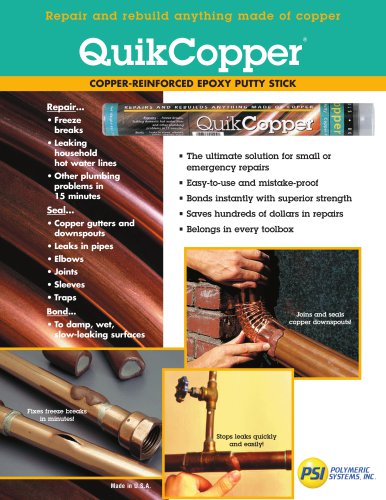

QuikCopper

2 Pages

-

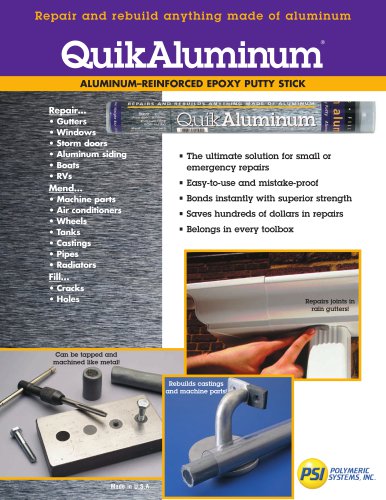

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

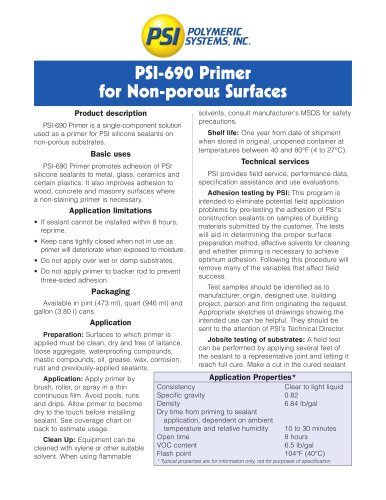

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

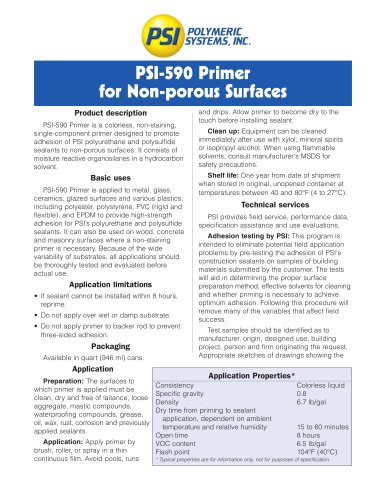

PSI-590TDS(1004-EM07)

2 Pages

-

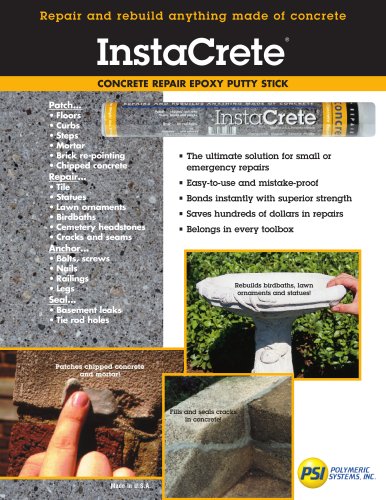

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

PSI-631TDS(7003-EM07)

3 Pages

-

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

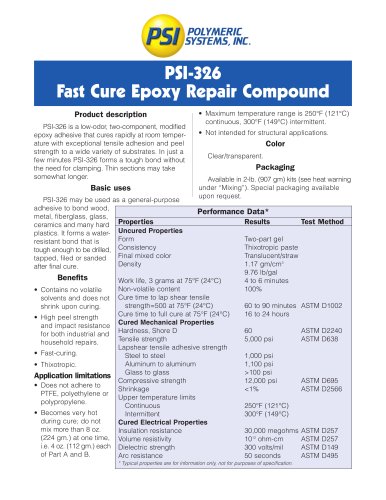

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages