Catalog excerpts

Non-corrosive Silicone Sealant Product description PSI-631 Non-Corrosive Silicone Sealant is a one-part, RTV, neutral cure, moisture curing sealant that is non-corrosive to all common building components. II cures to a tough, flexible rubber that has excellent primerless adhesion to glass, metals, vinyl building products, most plastics and painted surfaces. PSI-631 has little odor wher curing and has excellent weatherability, durability and recovery after movement. Basic uses PSI-631 can be used in most construction and remedial sealant applications, including conventional glazing of glass, plastic, metal panels and silicone-insulated window units; general purpose weather sealing of most construction materials including glass, aluminum, painted metal, steel, brick, concrete, other masonry substrates and many plastics; sealing expansion and control joints in precast concrete panels and metal curtain walls; interior sealant applications where harsh odor may be objectionable such as perimeter door and window seals, vents and duct work. • Highly flexible over a wide temperature range. • Excellent weather?.o ity. durability and recovery after movement. • Capable of compensating for joint movement of ±25% of the original joint width. • Little odor when curing. Application limitations • Should not be used on damp, frozen or contaminated surfaces. • Should not be used for structural or butt glazing, nor in expansion joints less than 1/4" in width • Not recommended for sealing exterior insulation finish systems (EIFS). • Should not be used in areas totally confined during cure as atmospheric moisture is required to trigger curing. • Not recommended for application to materials that might bleed oils or solvents. • Should not be used to seal natural stone, i.e., marble, light granite and limestone. • Not for use on surfaces with reflective or special protective coatings without prior testing. • Not recommended tor horizontal joints subject to abrasion such as decks, walks, driveways. etc., unless properly recessed. • Not for use to seal submerged and marine Clear, White, Black. Custom colors available; minumum order 100 gallons. cartridges, 12 cartridges per carton. Also available in 2 gallon pails, 5 gallon pails and 55 gallon drums on special order. Applicable standards PSI-631 meets or exceeds the requirements of Federal Specification TT-S-001543A, Class A; Federal Specification TT-S-00230C Type 2, Class A; ASTM C920-95 Type S, Grade NS, Class 25, Joint design: The width of the bead should be a minimum of 4 times the calculated movement. A thin bead of silicone sealant will accommodate more movement than a thick bead. PSI-631 should be installed no thicker than 1/2" and no thinner than 1/4". Ideally, the ratio of the joint width to depth should be 2:1 with the depth

Open the catalog to page 1

Closed cell polyethylene or polyurethane foam backer rod Is recommended for Installation into deep joints to control the depth. Bond breaker lape Is recommended for joints too shallow to allow the insertion of backer rod. These materials permit the application of a thin bead while providing a non-stick surface, precluding a three-sided joint. Glazing rabbets and joints should be designed to allow the insertion and retention of these bond-breaking materials during application PSI-631 is capable of compensating for joint movement of ±25% of the original joint width. Panels and lights of less...

Open the catalog to page 2

Health precautions • Application area should be well veniilaied. An irritating substance is evolved during cure. It high concentrations are inhaled for long periods of time health affects cannot • Uncured sealant may cause skin irritation. In case ot skin contact, remove with dry cloth or paper towel and wash with soap and water. • Uncured sealant may cause eye irritation. Contact lens wearers should take appropriate precautions. In case of eye contact, flush eyes with water and call physician. • Keep out of reach of children. For additional health and safety information, consult a Material...

Open the catalog to page 3All Polymeric Systems catalogs and brochures

-

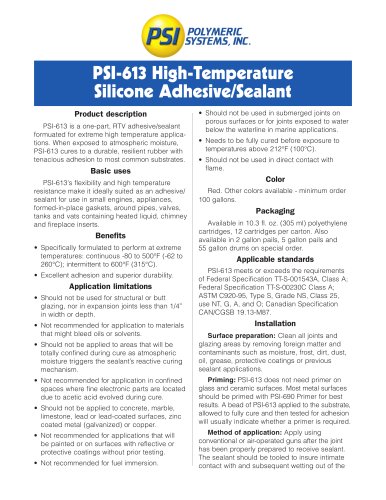

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

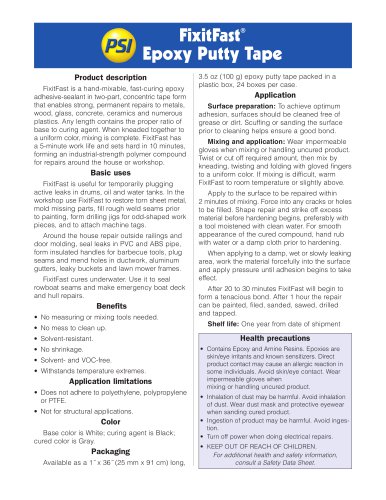

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

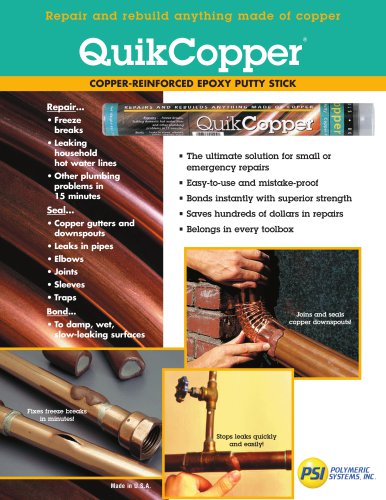

QuikCopper

2 Pages

-

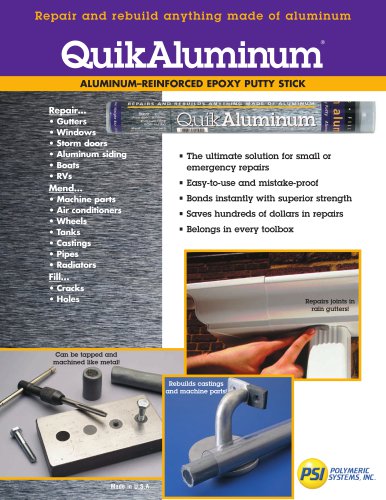

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

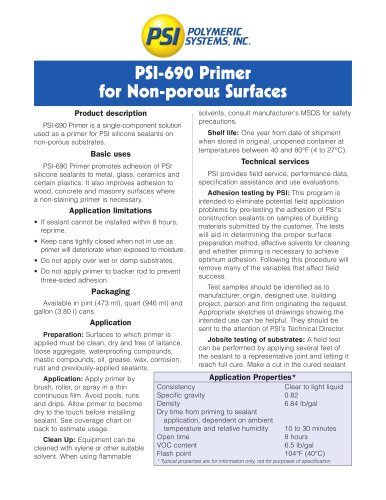

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

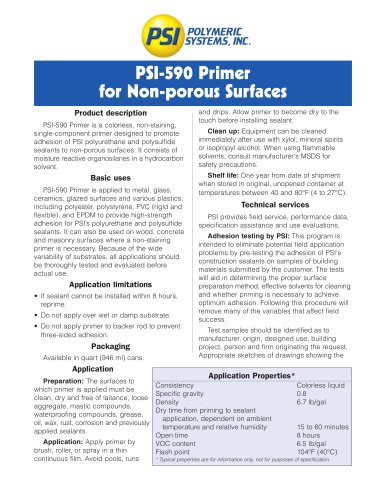

PSI-590TDS(1004-EM07)

2 Pages

-

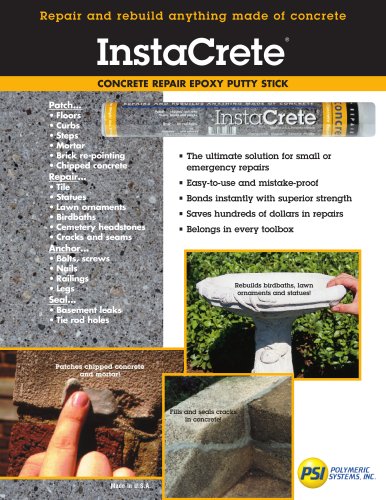

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

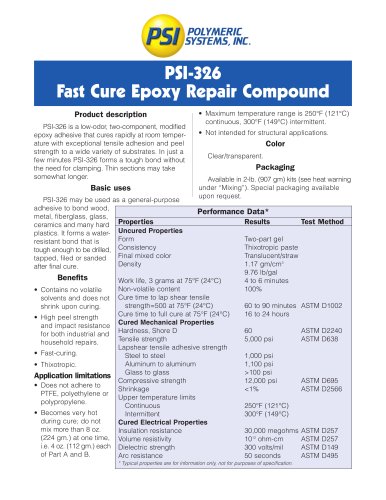

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages