Catalog excerpts

Silicone Adhesive/Sealant Product description lormuated for extremo high temperature applica- tions. When exposed to atmospheric moisture, PSI-613 cures lo a durable, resilient rubber with tenacious adhesion to most common substrates. Basic uses PSI-613's flexibility and high temperature resistance make it ideally suited as an adhesive/ sealant for use in small engines, appliances, formed-in-place gaskets, around pipes, valves, tanks and vats containing heated liquid, chimney • Specifically formulated to perform at extreme • Excellent adhesion and superior durability. Application limitations • Should not be used for structural or butt glazing, nor in expansion joints less than 1/4" • Not recommended for application to maierials that might bleed oils or solvents. • Should not be applied to areas that will be totally confined during cure as atmospheric moisture triggers the sealant's reactive curing • Not recommended for application in confined spaces where fine electronic parts are located due to acetic acid evolved during cure. • Should not be applied to concrete, marble, limestone, lead or lead-coated surfaces, zinc coated metal (galvanized) or copper. • Not recommended for applications that will be painted or on surfaces with reflective or protective coatings without prior testing. • Not recommended for fuel immersion. • Should not be used in submerged joints on porous surfaces or for joints exposed to water below the waterline in marine applications. • Needs to be fully cured before exposure to • Should not be used in direct contact with Red. Other colors available - minimum order cartridges, 12 cartridges per carton. Also available in 2 gallon palls, 5 gallon pails and 55 gallon drums on special order. Applicable standards PSI-613 meets or exceeds the requirements of Federal Specification TT-S-001543A, Class A; Federal Specification TT-S-00230C Class A; AST M C920-95, Type S, Grade NS, Class 25, Surface preparation: Clean all joints and glazing areas by removing foreign matter and contaminants such as moisture, frost, dirt, dust, oil, grease, protective coatings or previous sealant applications. Priming: PSI-613 does not need primer on glass and ceramic surfaces. Most metal surfaces should be primed with PSI-690 Primer for best results. A bead of PSI-613 applied to the substrate, allowed to fully cure and then tested for adhesion will usually indicate whether a primer is required. Method of application: Apply using conventional or air-operated guns after the joint has been properly prepared to receive sealant. The sealant should be tooled to insure intimate contact with and subsequent wetting out of the

Open the catalog to page 1

substrate. Excess sealant should be wiped trom the surrounding areas while still uncured and the area subsequently wiped with a commercial solvent such as naphtha or xylol. Consult the manutacturer's MSDS for safety precautions when using flammable solvents. Curing characteristics: PSI-6Î3 has a work life (tooling time) of 5 to 10 minutes. Moisture content of the air at the time of application has a direct influence on work life and cure speed. Health precautions • Application area should be well ventilated. • Acetic acid released during cure could cause eye or skin irritation. Contact lens...

Open the catalog to page 2

90° angle to determine if a good bond has developed. With good adhesion, the sealant will usually tear cohesively or be difficult to remove from the surface. Availability and cost Polymeric Systems, Inc., is a part of Whitford Worldwide. For more information, please contact Polymeric Systems or Whitford Plastics Ltd. at: Polymeric Systems, Inc. 47 Park Avenue Elverson, PA, USA 19520 800-CAULK IT (800-228-5548) Tel: [1] 610-286-2500 Email: sales@polymericsystems.com Website: polymericsystems.com In the EU contact: Whitford Plastics Ltd. 10, Christleton Court, Manor Park Runcorn, Cheshire, UK...

Open the catalog to page 3All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

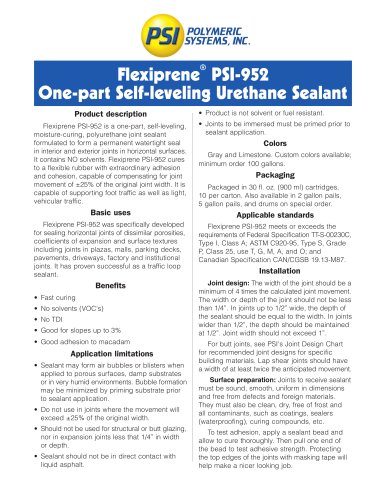

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

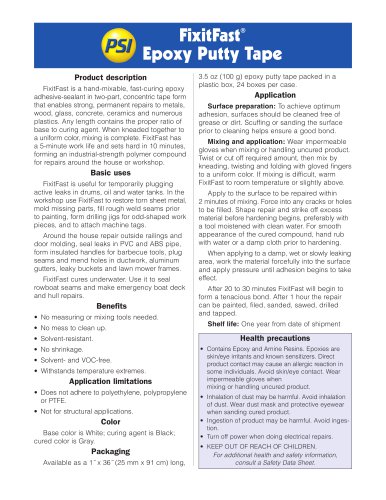

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

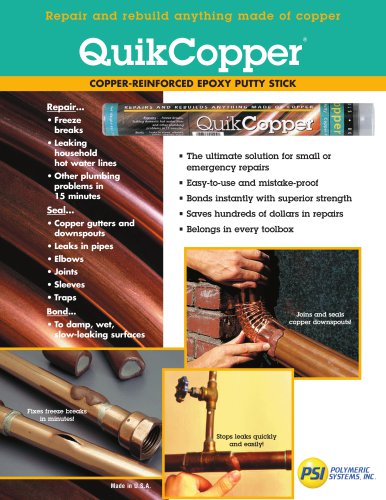

QuikCopper

2 Pages

-

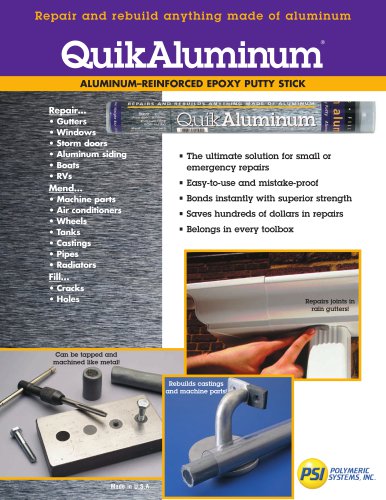

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

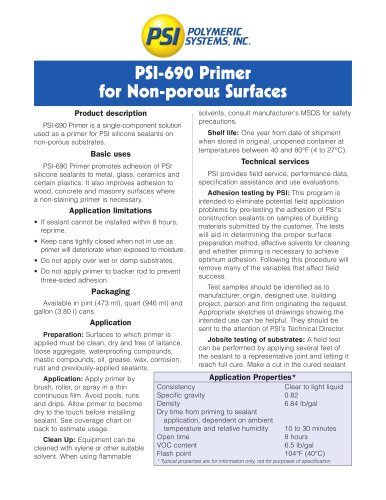

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

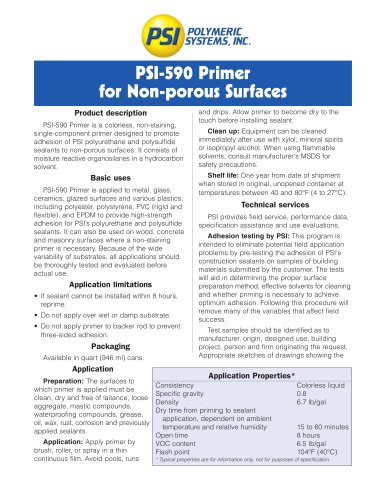

PSI-590TDS(1004-EM07)

2 Pages

-

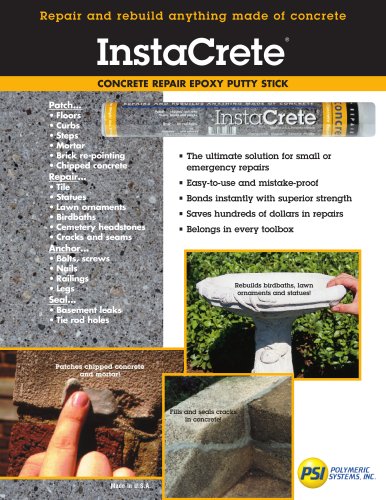

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

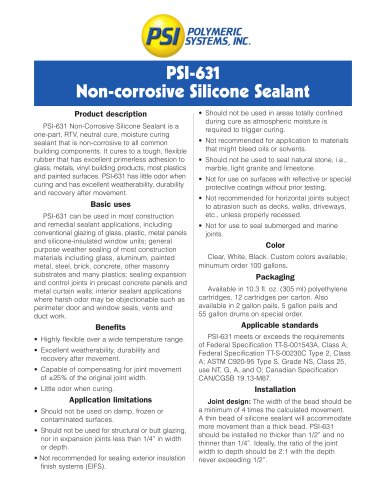

PSI-631TDS(7003-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

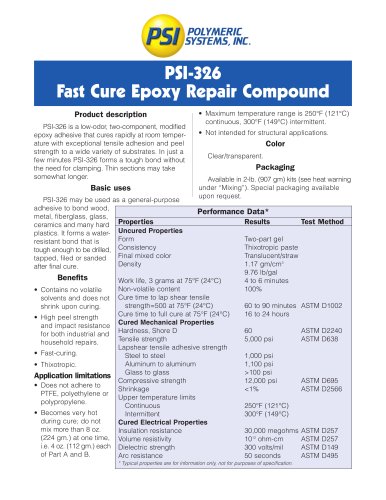

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages