Catalog excerpts

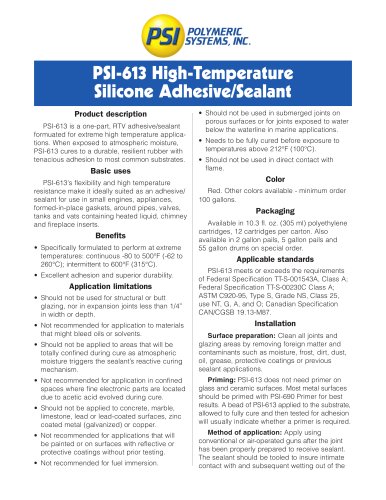

Product description PSI-613 is a one-part, room-temperature curing adhesive/sealant formulated for high-temperature applications. When exposed to atmospheric moisture, PSI-613 cures to a durable, resilient rubber with tenacious adhesion to most common substrates, Including glass, metal, ceramic, painted surfaces, many plastics, and rubber. Basic uses PSI-613's flexibility and high temperature resistance make it ideally suited as an adhesive/ sealant for use in small engine and automotive sealing applications; formed-in-place gaskets; appliances; heating elements; HVAC ductwork and flashing; stove and dryer exhausts; around pipes, valves, tanks and vats containing heated liquid; chimney and fireplace inserts. Benefits • Specifically formulated to perform at extreme temperatures: continuous -80 to 500°F (-62 to 260°C); intermittent to 600°F (315°C). • Excellent adhesion and superior durability. Application limitations • Should not be used for structural or butt glazing, nor in expansion joints less than 1/4" (6 mm) in width or depth. • Should not be applied to areas that will be totally confined during cure as atmospheric moisture triggers the sealant's reactive curing mechanism. • Releases acetic acid during cure; should not be applied to concrete, marble, limestone, lead or lead-coated surfaces, zinc coated metal (galvanized), copper, and fine electronic components. • Not recommended for applications that will be painted or on surfaces with reflective or protective coatings without prior testing. • Not recommended for fuel immersion. • Should not be used in submerged joints on porous surfaces or for joints exposed to water below the waterline in marine applications. • Should not be used in direct contact with flame. • Needs to be fully cured before exposure to temperatures above 212°F (100°C). Color Red. Packaging Available in 10.3 fl. oz. (305 ml) polyethylene cartridges, 12 cartridges per carton. Pail and drum packaging available. Applicable standards PSI-613 meets or exceeds the requirements of Federal Specification TT-S-001543A, Class A; Federal Specification TT-S-00230C Class A; ASTM C920-95, Type S, Grade NS, Class 25, use NT, G, A, and O; Canadian Specification CAN/CGSB 19.13-M87. Installation Surface preparation: Clean all joints and glazing areas by removing foreign matter and contaminants such as moisture, frost, dirt, dust, oil, grease, protective coatings or previous sealant applications. Priming: PSI-613 does not need primer on glass and ceramic surfaces. Most metal surfaces should be primed. A bead of PSI-613 applied to the substrate, allowed to fully cure and then tested for adhesion will usually indicate whether a primer is required. For primer recommendations, consult PSI technical services department. Method of application: Apply using conventional or air-operated guns after the joint has been properly prepared to receive sealant. The sealant should be tooled to insure intimate contact with and subsequent wetting of the substrate. Immediately wipe away excess sealant from the surrounding areas while still uncured and wipe the area with a commercial solvent such as isopropyl alcohol or mineral spirits. Consult the manufacturer's SDS for safety precautions when using flammable solvents. Curing characteristics: PSI-613 has a work life (tooling time) of 5 to 10 minutes. Normal skin-over time is 10 to 20 minutes. Air temperature and humidity at the time of application has a direct influence on work life and cure speed. Drier,

Open the catalog to page 1

colder conditions require more cure time. Shelf life: One year from date of shipment when stored in original, unopened container in a dry place at temperatures below 80° F (27°C). Health precautions Danger Causes serious eye irritation. May cause cancer. Refer to the Safety Data Sheet (SDS) for complete health and safety information. Maintenance If the sealant is damaged and the bond is intact, cut out the damaged area and recaulk. No primer is required. If the bond has been affected, remove the old sealant, clean and prepare the joint in accordance with the instructions under "Surface...

Open the catalog to page 2

Contact Details Polymeric Systems, Inc., is a part of Whitford Worldwide. For more information, please contact Polymeric Systems or Whitford Ltd. at: Polymeric Systems, Inc. Whitford Ltd. 47 Park Avenue 11 Stuart Road, Manor Park Elverson, PA, USA 19520 Runcorn, Cheshire, UK WA7 1TH Tel: [1] (610) 286-2500 Tel: [44] (0) 1928 571000 Email: sales@polymericsystems.com Email: salesuk@whitfordww.com Website: polymericsystems.com Website: whitfordww.com Toll Free: 800-CAULK IT (800-228-5548) NON-WARRANTY: ALL RECOMMENDATIONS, STATEMENTS AND TECHNICAL DATA CONTAINED HEREIN ARE BASED ON TESTS WE...

Open the catalog to page 3All Polymeric Systems catalogs and brochures

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

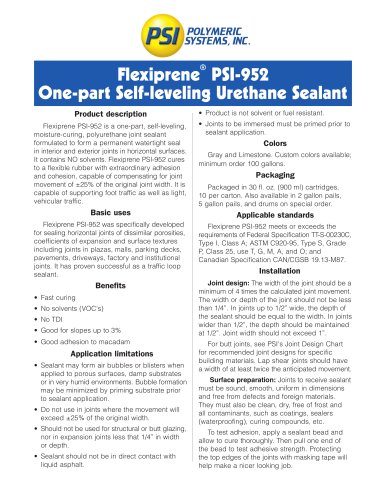

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

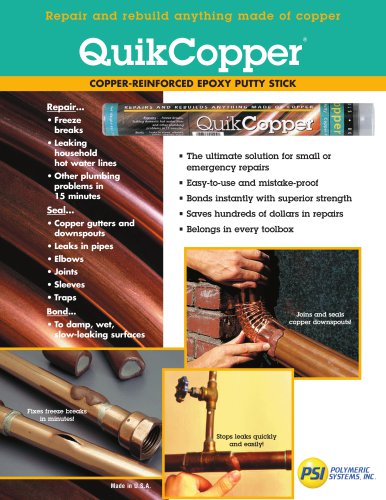

QuikCopper

2 Pages

-

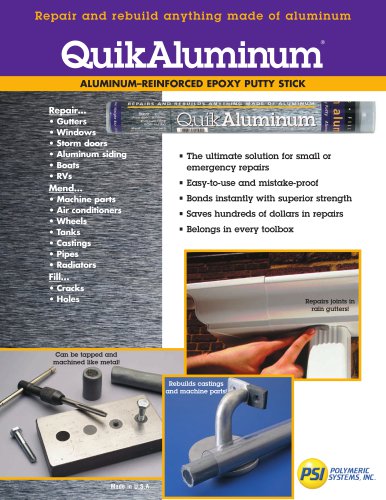

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

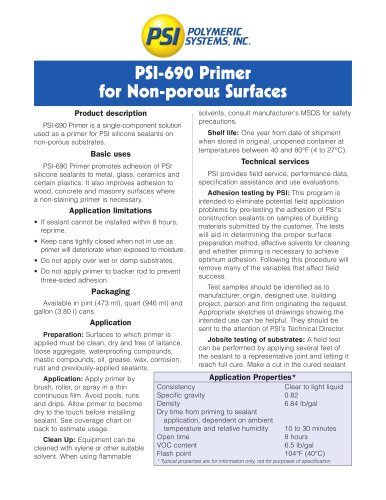

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

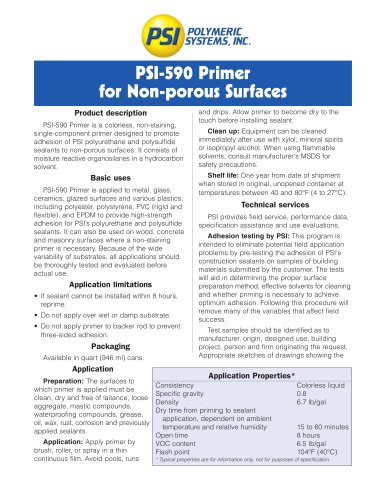

PSI-590TDS(1004-EM07)

2 Pages

-

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

PSI-631TDS(7003-EM07)

3 Pages

-

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages