Catalog excerpts

PSI-601 Acetoxy Silicone Sealant and PSI-601 FG Food Grade Acetoxy Silicone Sealant Product description PSI-601 and PSI-601 FG are one-part, RTV silicone sealants that cure by atmospheric moisture to a durable, flexible rubber with excellent adhesion to many surfaces, including glass, metal, wood, ceramic, porcelain, rubber, and some plastics. PSI-601 and PSI-601 FG may be factory or field applied to form a long-lasting seal resistant to the effects of rain, snow, ultraviolet radiation, ozone, sunlight and temperature extremes. Basic uses PSI-601 and PSI-601 FG exhibit excellent adhesion to non-porous substrates, making them extremely useful for butt and lap shear joints; glass block and glass partitions;curtain wall joints; non-structural glazing; skylights and mullions; cap, head and toe bead in conventional glazing; solar panels, duct work, vents and air conditioning units, and perimeter caulking of metal and most plastic frames. Benefits • Highly flexible over a wide temperature range. • UV- and ozone-resistant. • Excellent adhesion and superior durability on most non-porous surfaces. • Capable of compensating for joint movement of ±25% of the original joint geometry. • No sag, slump, or run-off. Application limitations • Only PSI-601FG is approved for use in food preparation areas. • Not for use in structural or butt glazing, nor in expansion joints less than 1/4" (6 mm) in width or depth. • Should not be applied to areas totally confined during cure as atmospheric moisture triggers the sealant's reactive curing mechanism. • Must be fully cured before exposure to temperatures above 217°F (103°C). • Not recommended for application to materials that might bleed oils or solvents. • Releases acetic acid during cure; should not be applied to concrete, marble, limestone, lead or lead-coated surfaces, zinc coated metal (galvanized) or copper. • Not recommended for applications that will be painted or surfaces with reflective or protective coatings without prior testing. • Not recommended for submerged joints on porous surfaces or for fuel immersion. Color PSI-601 is available in 3 colors: Clear, White and Aluminum. PSI-601 FG is available in Clear only. Custom colors are available; minimum order may apply. Packaging Available in 10.3 fl. oz. (305 ml) polyethylene cartridges, 12 cartridges per carton. Pail and drum packaging available. Applicable standards Both PSI-601 and PSI-601 FG comply with MIL-A-46106 and Southern Coast Air Quality Management District (SCAQMD) Rule 1168 for adhesives and sealants. PSI-601 FG complies with FDA 177.2600 \™y and is certified by the National Sanitation Foundation International (NSF) to Standard 51. Installation Joint design: The width of the bead should be a minimum of 4 times the calculated movement. A thin bead of sealant will accommodate more movement than a thick bead. PSI-601 and PSI-601 FG should be installed no thicker than 1/2" (12 mm) and no thinner than 1/4" (6 mm). Ideally, the ratio of the joint width to depth should be 2:1 with the depth never exceeding 1/2" (12 mm). Closed cell polyethylene or polyurethane foam backer rod is recommended to control the depth in deep joint installations. Bond breaker tape is recommended for joints too shallow for backer rod insertion. These materials permit the applica

Open the catalog to page 1

of a thin bead while providing a non-stick surface, precluding a three-sided joint. Glazing rabbets and joints should be designed to allow insertion and retention of these bond-breaking materials during application and curing of the sealant. Surface preparation: Clean all joints and glazing areas of foreign matter and contaminants such as moisture, frost, dirt, dust, oil, grease, protective coatings, previously applied sealants or glazing compounds. Priming: PSI-601 and PSI-601 FG adhere strongly to glass and ceramic surfaces and many common metals. For stronger, more uniform bonds, primers...

Open the catalog to page 2

All properties are at 70°F (21°C) and 50% RH Uncured Properties Skin-over time Cure time, 1/8" (3 mm) bead Sag/slump VOC content Specific gravity Density All cured properties below are at 7-day cure Cured Physical Properties Hardness, Shore A Tensile strength Elongation Service temperature, cured bead PSI-601 PSI-601 FG Cured Electrical Properties Dielectric constant, 60Hz Dielectric strength Cured Thermal Properties Volume coefficient of thermal expansion Thermal conductivity Cured Construction Properties Weight loss after heat aging Cracking and chalking after heat aging Durability (bond...

Open the catalog to page 3All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

Flexiprene® 1000

3 Pages

-

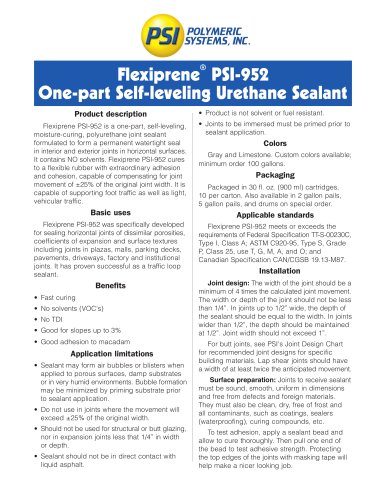

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

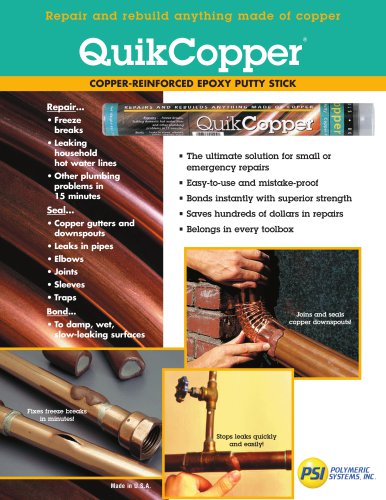

QuikCopper

2 Pages

-

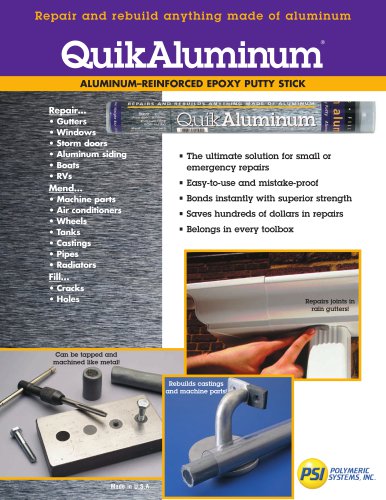

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

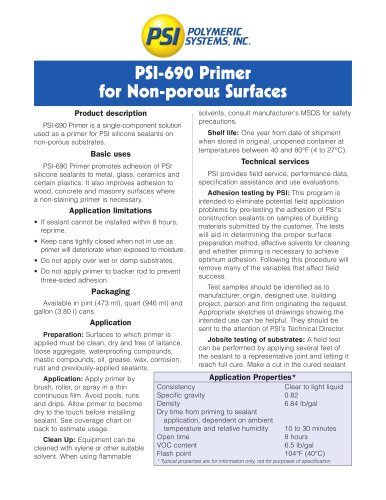

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

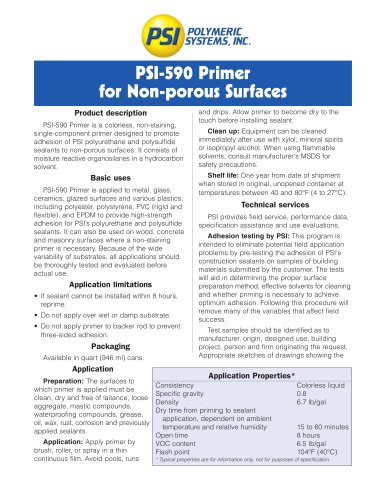

PSI-590TDS(1004-EM07)

2 Pages

-

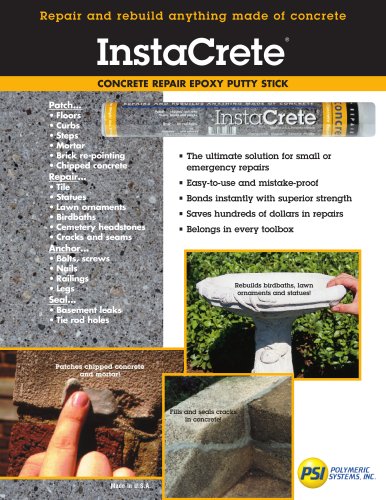

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

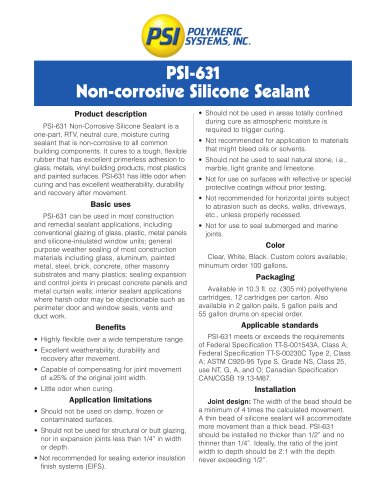

PSI-631TDS(7003-EM07)

3 Pages

-

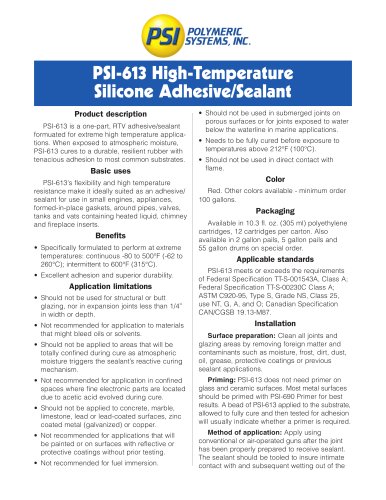

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

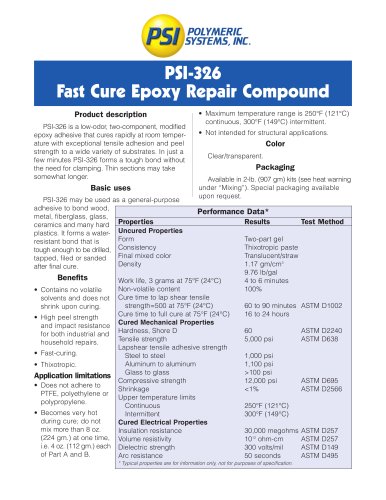

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages