Catalog excerpts

PSI-275 Multi-Component, Gun Grade, Polysulfide Sealant Product description PSI-275 Multi-Component Polysulfide Sealant is a three-part, chemically curing sealant that cures at ambient temperature to a medium-modulus, flexible, water-resistant rubber. PSI-275 provides a durable, flexible seal in joints in masonry, metal, concrete, plastics, glass, ceramics and wood. It is ideally suited for sealing vertical, horizontal, and sloping joints exposed to many chemicals and/or continuous water immersion. Basic uses The principal application for PSI-275 is sealing and caulking concrete joints subject to structural movement. Polysulfide sealants have a long history of successful use in continuous, total-immersion applications in swimming pools, reservoirs, and sewage treatment plants. PSI-275 has excellent chemical resistance and can also be used in many secondary containment applications. PSI-275 can be used as a universal joint sealant for a wide variety of building materials on both horizontal and vertical planes. It is ideal for sealing expansion and control joints in precast concrete panels and metal curtain walls. It can also be used for sealing interior and exterior control, expansion, and perimeter joints. Benefits • Durable, flexible seal provides excellent weatherability. • Improved product from the industry leader for over 30 years in sealants for underwater joints. • Contains no phthalate plasticizers. Application limitations • Not recommended for structural or butt glazing, nor in joints less than 1/4" (6 mm) in width or depth. • Not recommended for joints wider than 1-1/2" (38 cm). • Not recommended for application to certain architectural paints or finishes without prior testing. • Not recommended for areas subject to harsh chemicals without prior testing. • Not recommended for total immersion applications without specified primer. • For chlorinated water applications where the chlorine content exceeds 5 ppm, contact PSI Customer Service for specific use limitations. • Temperatures below 50°F (10°C) retard cure. Color Limestone, Gray, and Black. Packaging Available in 1-1/2-US-gallon (5.68-liter) pails. Applicable standards PSI-275 meets or exceeds the requirements of Federal Specification TT-S-00227E Type II, Class A in all respects except Section 3.5.7 Stain and Color Change; ASTM C920 Type M, Grade NS, Class 25, Use NT, G, M, and A with the exception of ASTM C510, Stain and Color Change; SWI 2B; and CAN/CGSB 19.24-M90. PSI-275 meets the test requirements of ASTM C1247 for sealants exposed to continuous immersion in liquids. PSI-275 complies with Southern Coast Air Quality Management District (SCAQMD) Rule 1168 for adhesives and sealants. Installation Joint design: It is recommended that dimensions be established for each joint in accordance with service conditions. Generally, the width of the joint is determined by calculating the joint width change associated with thermally induced expansion and contraction of the structure expected from temperature extremes which it will encounter, and multiplying this figure by a factor of 4. For example, if the calculated total movement of the joint under temperature extremes is 1/4" (6 mm), the joint should be designed no less than 1/4" (6 mm) x 4, or 1" (25 mm) wide. Surface preparation: All surfaces must be dry, clean, and free of loose aggregate, laitance, corrosion, oil, tar, grease, asphalt, paint, mastic compounds, waterproofing agents, release agents and wax. Joints must be protected from contamination by bituminous or resinous materials that are sometimes sprayed on new concrete to aid

Open the catalog to page 1

in curing. After joints have been cleaned, care should be taken to avoid contamination during the priming and sealing operation. Priming: PSI-275 adheres to most common substrates such as glass, ceramic, aluminum, steel, PVC, concrete and wood; however, priming is recommended for optimum adhesion. PSI-75 Primer is recommended for non-porous surfaces such as plastics and rubber; porous surfaces such as masonry; and areas that will be frequently wet, damp, or underwater. Primer should be applied only to a clean, dry surface prior to installation of backer rod, bond breaker tape and sealant....

Open the catalog to page 2

puncture the backer rod. Rod stock diameter should be at least one grade larger than the joint width at the time of installation to ensure compression when inserted. Where room does not exist for the rod, bond-breaker tape should be inserted to prevent three-sided bonding. All nonextruding and resilient-type preformed expansion joint fillers shall conform to the requirements and tests set forth in ASTM D1752 for Type I materials, except as otherwise specified herein. Mixing: Add Activator and Color Pack to Base in the Base pail and mix with a slow speed 1/2" (12 mm) drill and a flat mixing...

Open the catalog to page 3

Contact Details Polymeric Systems, Inc., is a part of Whitford Worldwide. For more information, please contact Polymeric Systems or Whitford Ltd. at: Polymeric Systems, Inc. Whitford Ltd. 47 Park Avenue 11 Stuart Road, Manor Park Elverson, PA, USA 19520 Runcorn, Cheshire, UK WA7 1TH Tel: [1] (610) 286-2500 Tel: [44] (0) 1928 571000 Email: sales@polymericsystems.com Email: salesuk@whitfordww.com Website: polymericsystems.com Website: whitfordww.com Toll Free: 800-CAULK IT (800-228-5548) NON-WARRANTY: ALL RECOMMENDATIONS, STATEMENTS AND TECHNICAL DATA CONTAINED HEREIN ARE BASED ON TESTS WE...

Open the catalog to page 4All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

Flexiprene® PSI-952

3 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

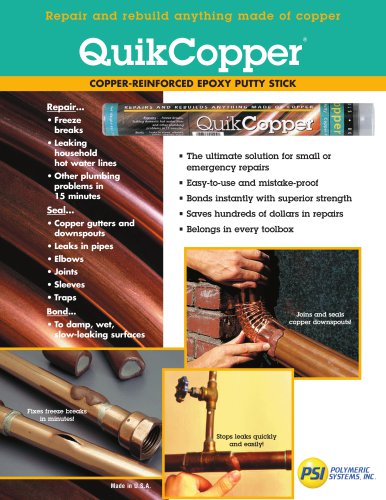

QuikCopper

2 Pages

-

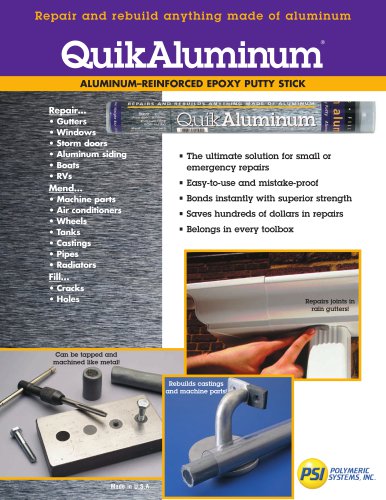

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

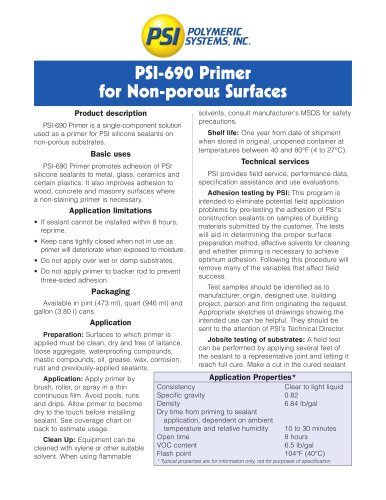

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

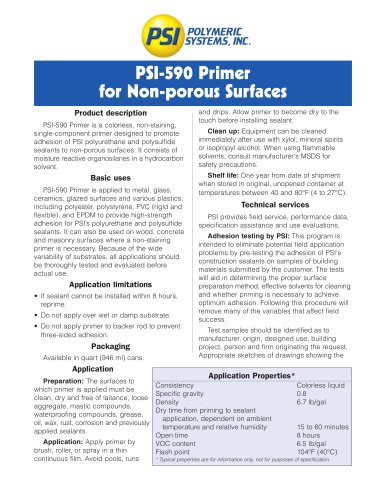

PSI-590TDS(1004-EM07)

2 Pages

-

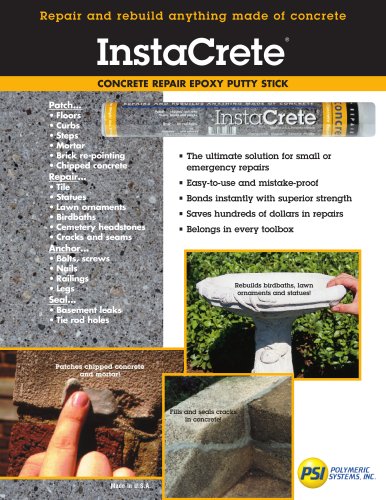

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

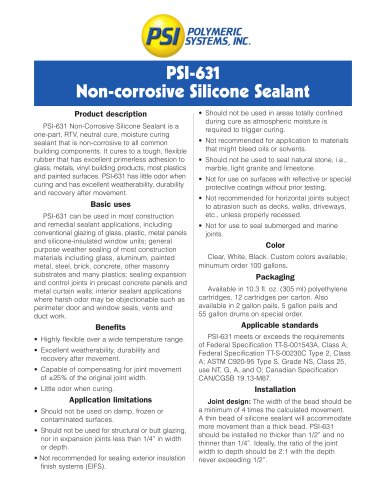

PSI-631TDS(7003-EM07)

3 Pages

-

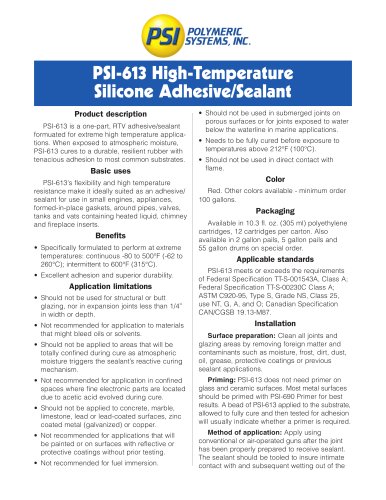

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

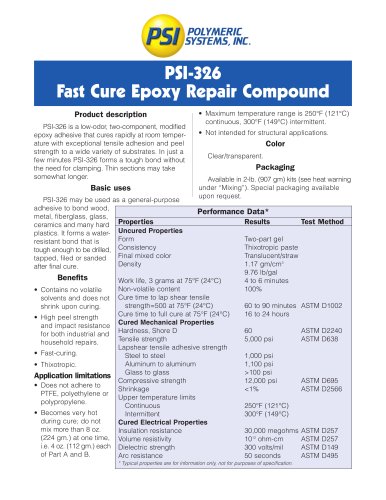

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages