Catalog excerpts

PSI Primer #67 Product description PSI Primer #67 is a two-part epoxy/polyamide primer for concrete and galvanized steel. Basic uses PSI Primer #67 is applied to concrete and galvanized steel to provide excellent adhesion for PSI polysulfide and polyurethane sealants, particularly in water immersion applications. Application limitations • Do not apply over wet or damp surfaces. • Contains flammable solvents; adequate ventilation required. • Do not apply primer to backer rod to prevent three-sided adhesion. Color Clear amber. Application: After mixing Part A with Part B in their proper proportions, the mixture should stand for 30 minutes before use. It can then be applied to the clean surface by brush in a uniform thickness free of sags. A minimum dried film thickness of 1.0 to 1.5 mils is recommended. When multiple coats are applied, allow the final coat 2 to 3 hours of drying time at 75°F (24°C) and 50% relative humidity. Lower temperature or high humidity will increase the initial dry time. After mixing Part A with Part B PSI Primer #67 must be applied within the “Application life” times shown in Application Properties below. Do not mix fresh material with material nearing the end of its application life. Clean up: Equipment can be cleaned with solvents such as xylene or mineral spirits. Avoid ignition sources. Consult manufacturer's MSDS for safety precautions. Packaging Available in pint (473 ml) and quart (946 ml) kits. Application Properties* Color: Part A Clear to light yellow Part B Amber Application Mixing ratio by weight or volume 1:1 Preparation: The surface to which Consistency Colorless liquid the primer is to be applied must be Specific gravity 0.8 clean, dry and free of oil, tars, paint Density 6.7 lb/gal and other surface contamination. Min. recommended film thickness 1.0 to 1.5 mils Concrete surfaces must be sand(0.025 to 0.037 mm) blasted or wire brushed until laitance- Application life: at 40°F (4°C) 16 hours free. at 75°F (24°C) 8 hours at 100°F (38°C) 3 hours Mixing: PSI Primer #67 is supplied at 120°F (49°C) 1 hours in two-part, premeasured kits. Pour Open time 8 hours entire contents of Part A into Part B Dry time before sealant application and thoroughly mix. Slow mixing by at 75°F (24°C) & 50% RH 3 hours minimum hand or with a standard paint shaker 24 hours maximum is recommended. The material should VOC content 4.6 lb/gal be stirred occasionally during use. Flash point: Part A 51°F (11°C) CAUTION: DO NOT MIX PART A Part B 44°F (7°C) AND PART B TOGETHER UNTIL * Typical properties are for information only, not for purposes of specification. READY TO USE.

Open the catalog to page 1

Maintenance: PSI sealants must be applied between 3 and 24 hours after application of PSI Primer #67. If the primer dries more than 24 hours, reprime the surface. Shelf life: At least one year from date of shipment when stored at temperatures below 80°F (27°C) in original, unopened containers. Technical services PSI provides field service, performance data. specification assistance and use evaluations. Adhesion testing by PSI: This program is intended to eliminate potential field application problems by pre-testing the adhesion of PSI's construction sealants on samples of building materials...

Open the catalog to page 2All Polymeric Systems catalogs and brochures

-

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

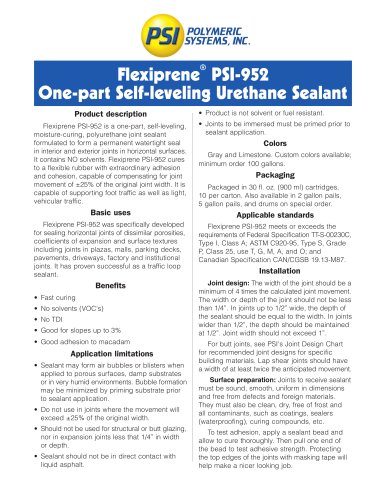

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

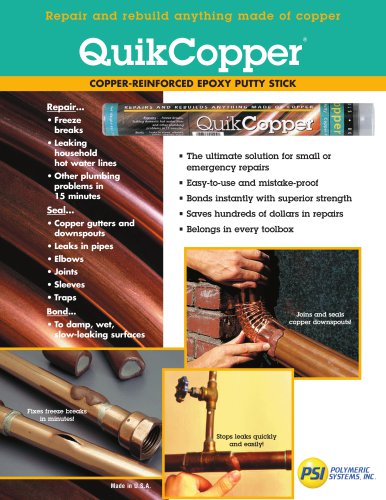

QuikCopper

2 Pages

-

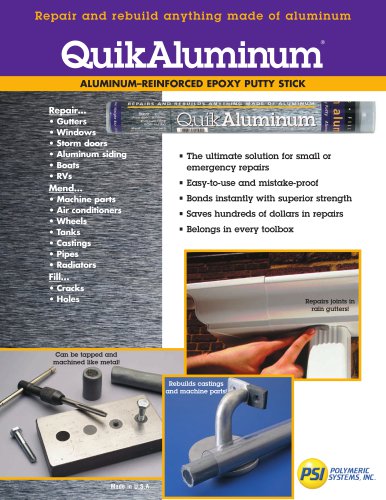

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

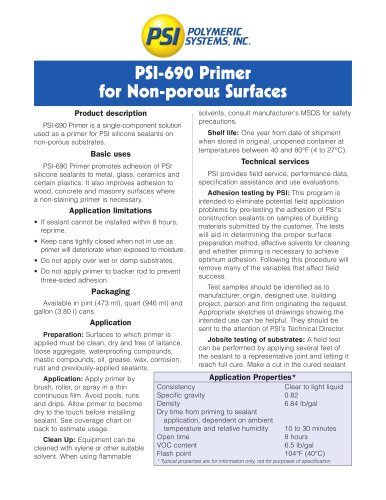

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

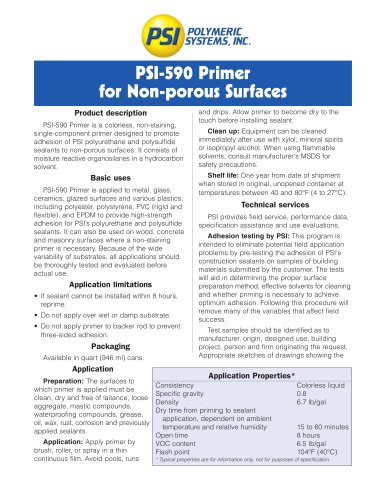

PSI-590TDS(1004-EM07)

2 Pages

-

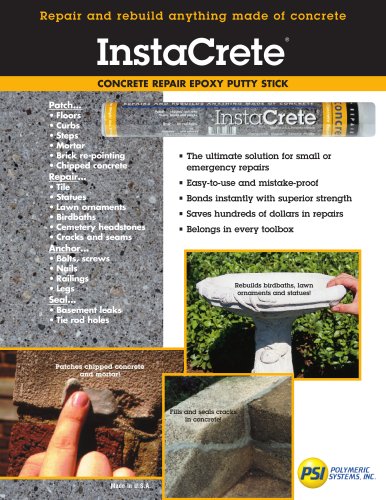

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

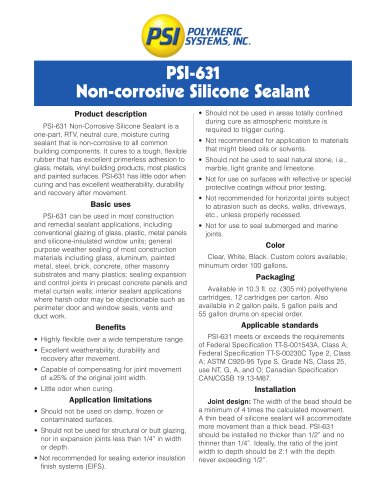

PSI-631TDS(7003-EM07)

3 Pages

-

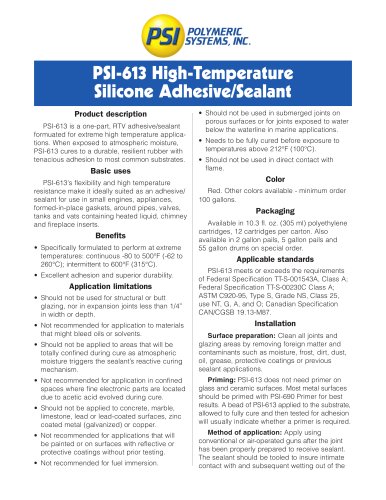

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

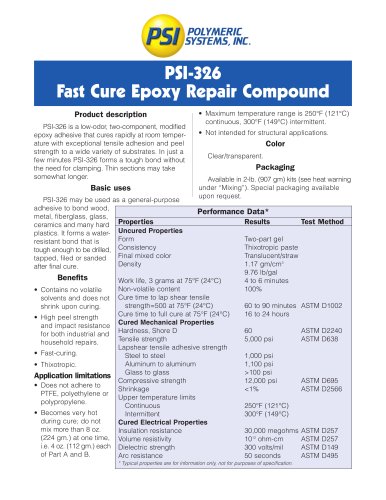

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages