Catalog excerpts

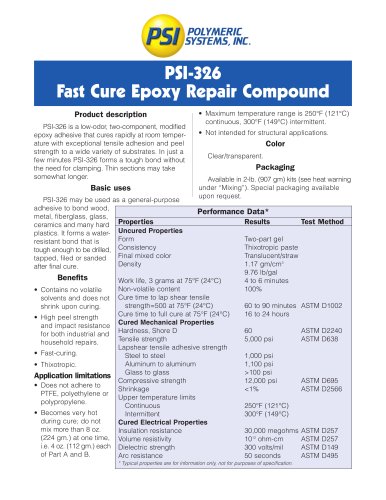

(formerly PSI-326 Fast-Cure Epoxy Repair Compound) Product description MIX2FIX FC Translucent Adhesive is a low-odor, two-component, modified epoxy adhesive that cures rapidly at room temperature with exceptional tensile adhesion and peel strength to a wide variety of substrates. Just a few minutes after application it forms a tough bond without the need for clamping. Basic uses MIX2FIX FC Translucent Adhesive may be used as a general-purpose adhesive to bond wood, metal, fiberglass, glass, ceramics and many hard plastics. It forms a strong bond that is tough enough to be filed, drilled, tapped, or sanded after final cure. Benefits • Contains no volatile solvents and does not shrink upon curing. • High peel strength and impact resistance for both industrial and household repairs. • Excellent adhesion to a wide variety of substrates. • Fast-curing. How to use Surface preparation: To achieve optimum adhesion, surfaces should be dry and free of grease or dirt. Scuffing or sanding the surface prior to cleaning helps insure a good bond. Mixing and application: Wear impermeable gloves when mixing or handling uncured product. Mix equal portions of resin (Part A) and hardener (Part B) by weight or volume until uniform. Do not mix more than 8 oz. (224 g.) total at one time, i.e., 4 oz. (112 g.) each of Part A and Part B. Material may become hot during cure. Use within 3 minutes of mixing. Remove excess material before product begins to set. Allow MIX2FIX FC Translucent Adhesive to harden until a strong bond has formed before handling or returning to service, normally 60 to 90 minutes depending on the nature of the application. Product cures faster at higher temperatures and larger volumes. Product cures slower at lower temperatures and in thin sections. Shelf life: One year from date of shipment when stored in original, unopened containers at 75°F (24°C). Health precautions Application limitations • Does not adhere to PTFE, polyethylene or polypropylene. • Becomes very hot during cure; do not mix more than 8 oz. (224 g.) total at one time, i.e. 4 oz. (112 g.) each of Part A and Part B. • See performance data for temperature limits. • Do not apply at temperatures below 41°F (5°C). • Not intended for structural applications. Color Cured color is Translucent. Packaging Available in 2-lb. (907g) kits. Special packaging available upon request. • Contains Epoxy Resin. Epoxies are skin/eye irritants and known sensitizers. Direct product contact may cause an allergic reaction in some individuals. Avoid skin/eye contact. Wear impermeable gloves when mixing or handling uncured product. • Inhalation of dust may be harmful. Avoid inhalation of dust. Wear dust mask and protective eyewear when sanding cured product. • Ingestion of product may be harmful. Avoid ingestion. • KEEP OUT OF THE REACH OF CHILDREN. For additional health and safety information, consult a Safety Data Sheet.

Open the catalog to page 1

Performance Data* Properties Uncured Properties Composition Physical appearance Odor (hardener) Mixing ration by weight or volume Mixed density Application temperature Work life, 3 grams at 75°F (24°C) Handling time at 75°F (24°C) Return to service time at 75°F (24°C) Cured Mechanical Properties Physical appearance when cured Hardness, Shore D Tensile strength Lapshear tensile adhesive strength Steel to steel Aluminum to aluminum Glass to glass Compressive strength Temperature limits Continuous Intermittent Chemical resistance Test Methods Two-part epoxy adhesive Gel Strong sulphurous smell...

Open the catalog to page 2All Polymeric Systems catalogs and brochures

-

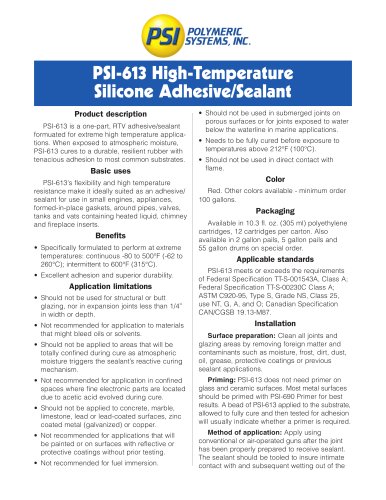

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

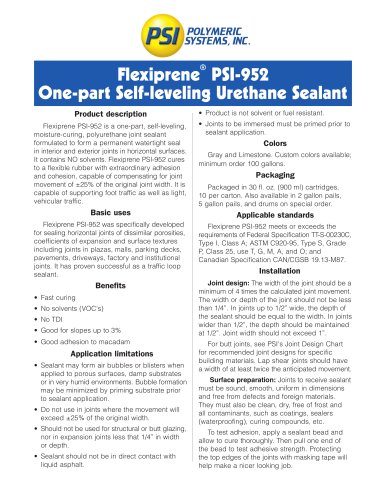

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

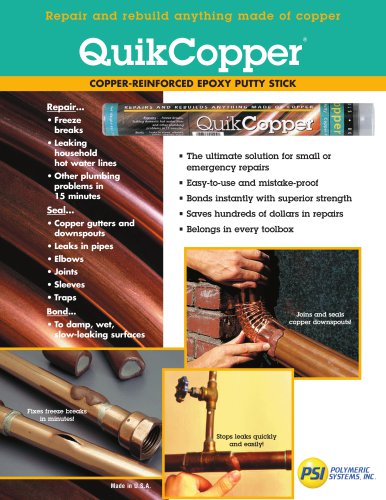

QuikCopper

2 Pages

-

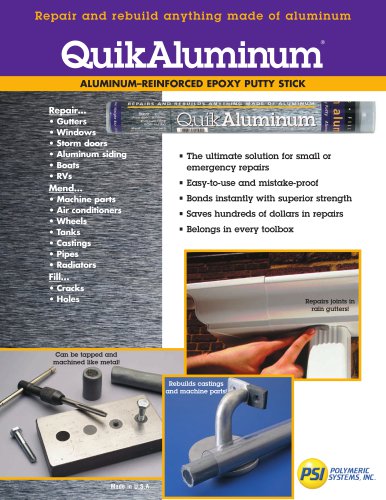

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

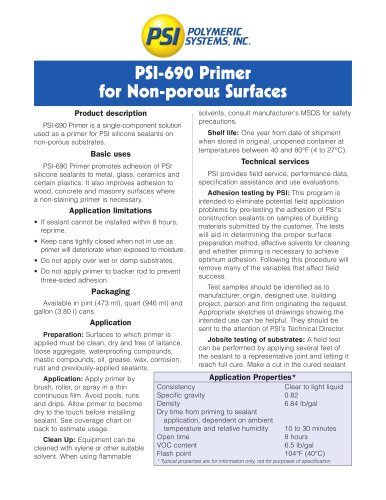

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

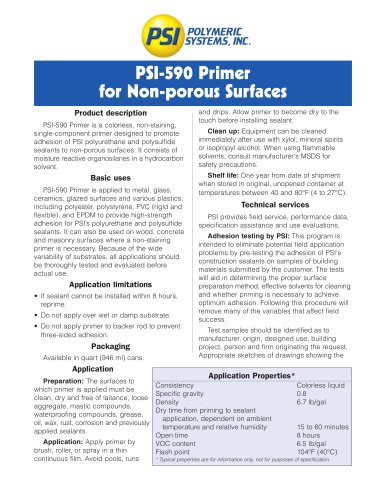

PSI-590TDS(1004-EM07)

2 Pages

-

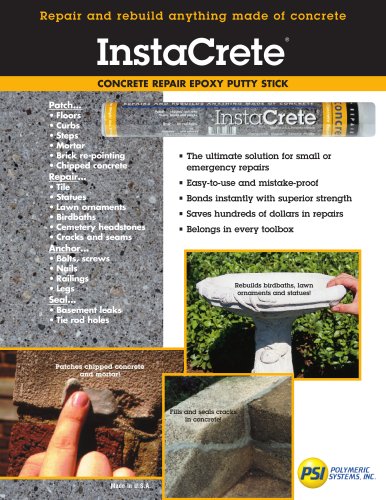

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

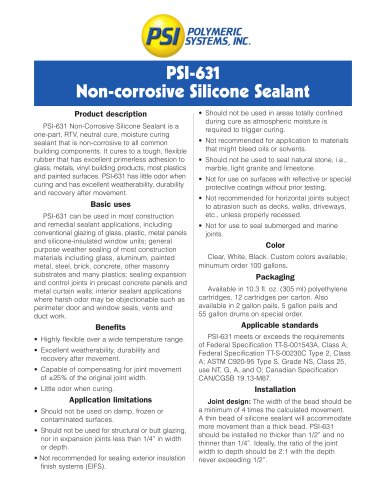

PSI-631TDS(7003-EM07)

3 Pages

-

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages

-

Flex952TDS(1020-EM07)

3 Pages