Catalog excerpts

One-part Self-leveling Urethane Sealant Product description Flexiprene PSI-952 is a one-part, self-leveling, moisture-curing, polyurethane joint sealant formulated to form a permanent watertight seal in interior and exterior joints r horizontal surfaces. It contains NO solvents. Flexiprene PSI-952 cures lo a flexible rubber with extraordinary adhesion and cohesion, capable of compensating for joint movement of ±25% of the original joint width. It is capable of supporting foot traffic as well as light, vehicular traffic. Basic uses Flexiprene PSI-952 was specifically developed for sealing horizontal joints of dissimilar porosities, coefficients of expansion and surface textures including joints in plazas, malls, parking decks, pavements, driveways, factory and institutional joints. It has proven successful as a traffic loop • Fast curing • Good adhesion to macadam Application limitations • Sealant may form air bubbles or blisters when applied to porous surfaces, damp substrates or in very humid environments. Bubble formation may be minimized by priming substrate prior • Do not use in joints where the movement will exceed ±25% of the original width. • Should not be used for structural or butt glazing. nor in expansion joints less that 1/4" In width • Sealant should not be In direct contact with liquid asphalt. • Product is not solvent or fuel resistant. • Joints to be Immersed must be primed prior to sealant application. Gray and Limestone. Custom colors available; minimum order 100 gallons. 10 per carton. Also available in 2 gallon pails, 5 gallon pails, and drums on special order. Applicable standards Flexiprene PSI-952 meets or exceeds the requirements of Federal Specification TT-S-00230C, Type I, Class A; AST M C920-95, Type S. Grade Canadian Specification CAN/CGSB 19.13-M87. Joint design: The width of the joint should be a minimum of 4 times the calculated joint movement. The width or depth of the joint should not be less than 1/4". In joints up to 1/2" wide, the depth of the sealant should be equal to the width. In joints wider than 1/2", the depth should be maintained at 1/2". Joint width should not exceed 1 ". For butt joints, see PSI'S Joint Design Chart for recommended joint designs for specific building materials. Lap shear joints should have a width of at least twice the anticipated movement. Surface preparation: Joints to receive sealant must be sound, smooth, uniform in dimensions and free from defects and foreign materials. They must also be clean, dry, free of frost and all contaminants, such as coatings, sealers (waterproofing), curing compounds, etc. To test adhesion, apply a sealant bead and allow to cure thoroughly. Then pull one end of the bead to test adhesive strength. Protecting the top edges of the joints with masking tape will help make a nicer looking job.

Open the catalog to page 1

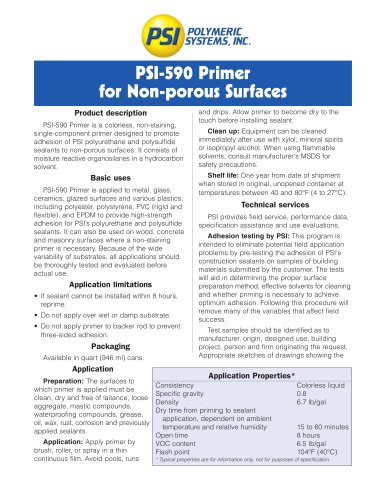

Priming: Flexiprerie PSI-952 has excellent adhesion to mosl common firm.unconiaminated materials. It may be prudent to use a primer on substrates such as concrete which are frequently wet, friable or sandy, and some plastics. For porous surfaces, PSI Primer 591 Is recommended. The primer should be allowed to dry for about 2 hours before applying sealant. For non-porous surfaces, Primer 590 is recommended. Sealant can be applied after a 15-minute drying time. Primer should be applied only to clean, dry surfaces prior to installation of backer rod, bond breaker tape, and sealant and should be...

Open the catalog to page 2

Technical services Availability and cost PSI provides field service, performance data, specification assistance and use evaluations. Polymeric Systems, Inc., is a part of Whitford Worldwide. For more information, please contact Polymeric Systems or Whitford Plastics Ltd. at: Adhesion testing by PSI: This program is intended to eliminate potential field application problems by pre-testing the adhesion of PSI's construction sealants on samples of building materials submitted by the customer. The tests will aid in determining the proper surface preparation method, effective solvents for...

Open the catalog to page 3All Polymeric Systems catalogs and brochures

-

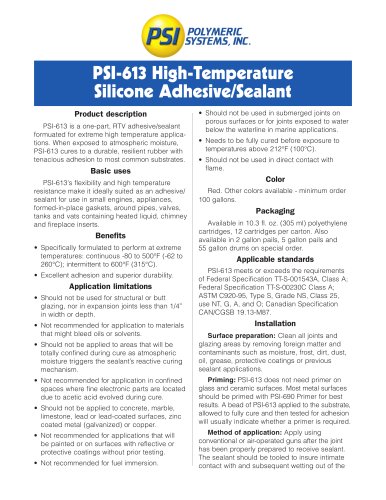

PSI-613

3 Pages

-

PSI-601

3 Pages

-

Flexiprene® 1000

3 Pages

-

Flexiprene® PSI-952

3 Pages

-

PSI-275

4 Pages

-

MIX2FIX® FC

2 Pages

-

MIX2FIX®

2 Pages

-

Kneadatite®

2 Pages

-

RepairitQuik®

2 Pages

-

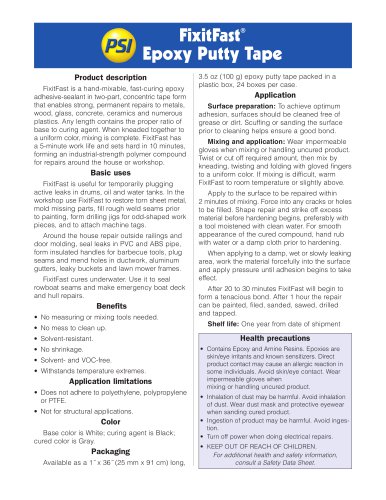

FixitFast ®

2 Pages

-

AquaMend

2 Pages

-

QuikWood

2 Pages

-

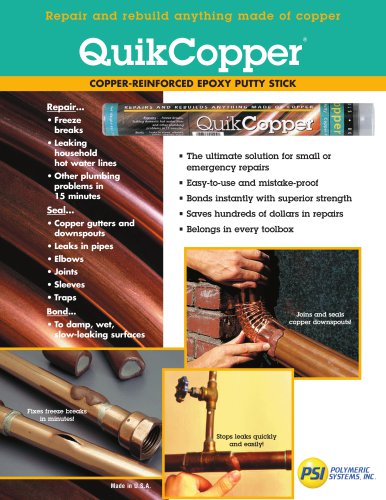

QuikCopper

2 Pages

-

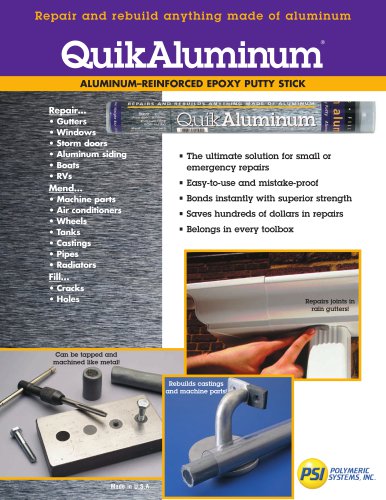

QuikAluminum

2 Pages

-

FastSteel

2 Pages

-

QuikPlastik(4023-0908)

2 Pages

-

PSI-691TDS(7007-EM07)

2 Pages

-

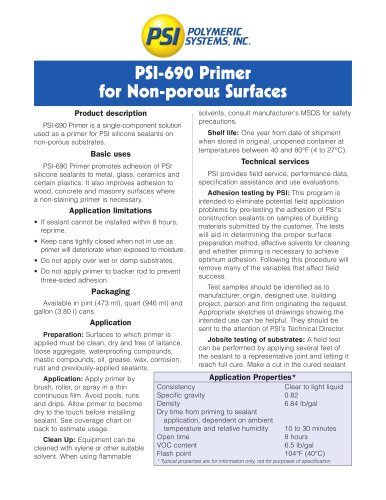

PSI-690TDS(7006-EM07)

2 Pages

-

PSI-591TDS(1005-EM07)

2 Pages

-

PSI-590TDS(1004-EM07)

2 Pages

-

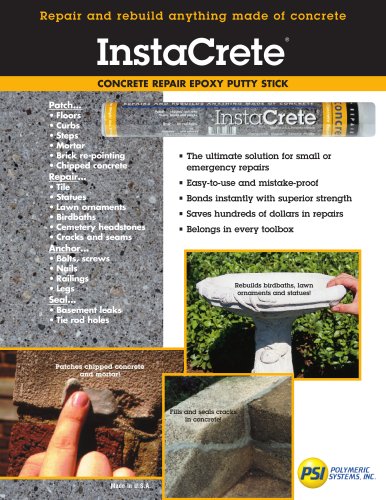

InstaCrete(4020-0908)

2 Pages

Archived catalogs

-

PSI-641TDS(7005-0808)

3 Pages

-

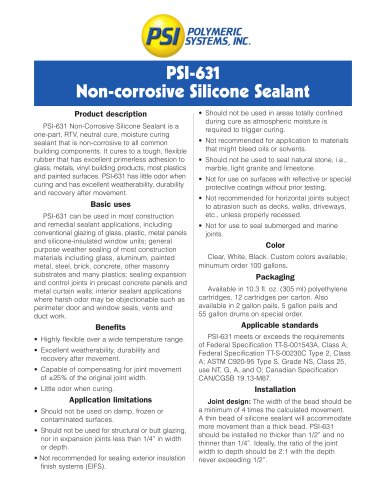

PSI-631TDS(7003-EM07)

3 Pages

-

PSI-613TDS(7002-EM07)

3 Pages

-

PSI-601TDS(7000-0808)

3 Pages

-

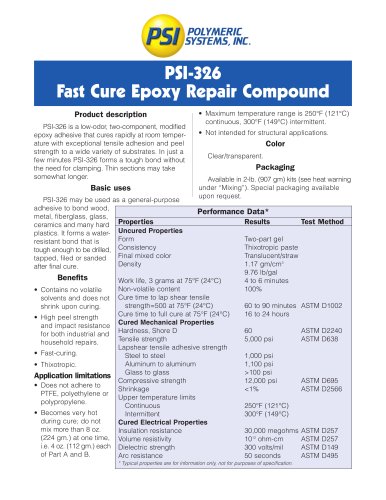

PSI-326 TDS(2008-1009)

2 Pages

-

PSI-75 Primer (1023-0510)

2 Pages

-

Primer67TDS(1010-EM07)

2 Pages

-

Flex1000TDS(1015-EM07)

3 Pages