Catalog excerpts

Hydrocarbon Filtration climate control process control sealing & shielding ENGINEERING YOUR SUCCESS.

Open the catalog to page 1

Hydrocarbon Filtration Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 2

Hydrocarbon Filtration assemblies are designed to meet the toughest hydrocarbon refueling condi- tions and provide for ease of filter change outs. The FBO Assembly can the elements installed and fuel being used on mobile refuelers or installed in refueling cabinets. The unit can also be used for diesel fuel dispensing pumps or as a primary fuel filter/wa- ter separator for large diesel engines. The assembly features a locking ring collar, which attaches the filter housing to the aluminum die-cast filter head with four bolts. The slotted locking ring collar allows maintenance personnel to...

Open the catalog to page 3

Hydrocarbon Filtration Below is a guide to help customers order the right FBO assembly with the accessories you need. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 4

Hydrocarbon Filtration Flow Rates DPL = Delta P Gauge with Liquid Sight Glass MA = Marine Unit Assembly 25M = Unit with 25 Micron HTR = Unit with 120 volt Cartridge Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 5

Hydrocarbon Filtration Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 6

Hydrocarbon Filtration Mounting Information Fuel Tank Above Filter (Head pressure should not 1 (Pressure Side Installation) Install shut-off valve when fuel tank is higher than filter. Fuel Tank (Ideal Vacuum Side To maintain prime, install check valve (with light or no restriction when tank is lower than filter. Fuel Tank (Vacuum Side Installation) Fuel Tank Below Filter (Lift should not exceed 4 inHg.) Optional Fuel Transfer Pump or flow rate of filter. NOT ideal— pumps emulsify water hindering filter performance. stalled in each side of shut off during element sembly maintenance. Fuel...

Open the catalog to page 7

Hydrocarbon Filtration Replacement Parts Part Number Handle Assembly Differential Pressure Gauge (DP Gauge) Head Kit with DP Gauge FBO-10 Housing Assembly (includes #'s 5 & FBO-14 Housing Assembly (includes #'s 5 & Installation Instructions Optional Parts (not shown) 73231 1/2" DIA. 120 volt Cartridge Heater Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 8

Hydrocarbon Filtration RHFM Series Fuel Monitor Vessels The RHFM Series Horizontal Fuel Monitor Vessels, equipped with the FMI or FM Series Fuel Monitor car- tridges, check the entire flow of fuel, collecting solids, absorbing water and ensuring only clean and dry fuel for delivery. Racor Hydrocarbon FMI 2 Inch Series Monitor Cartridges are qualified to the latest edition of API/ Procedures. The vessels can also be equipped with FM 2 Inch Series cartridges that are qualified to MIL- ries Monitor Cartridges are designed to flow from the outside to inside at a rate of one gallon (3.79 liters)...

Open the catalog to page 9

Hydrocarbon Filtration RHFM Series Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 10

Hydrocarbon Filtration RHFM Series Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 11

Hydrocarbon Filtration RHFS Series Horizontal Coalescer Separator Vessel Hie RVFS/5 Series Filter Water Separator Vessels are for use with RST Series Separator Cartridges. Racor hydrocarbon RVFS/5 Series two-stage vertical and horizontal coalescer/ separator housings are designed to filter solids and separate free water from jet fuel. Using the correct combination of Racor hydrocarbon coalescer cartridges and second stage separator cartridges will provide the highest degree of water and solids • Loading racks • Hydrant carts and refuelers • Inlet and Outlet: 150# RF (ANSI) •Vent and...

Open the catalog to page 12

Hydrocarbon Filtration RHFS Series • Carbon steel construction; other materials available • ASME Code, Section VIII construction, • Zinc-plated swing bolt closure • Buna-N o-ring cover seal • Hydraulic jack cover lift • Inlet and outlet permanently marked • Exterior: prime coated • Knife-edge cartridge mounting seals Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 13

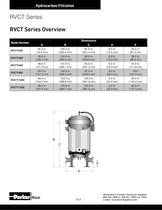

Hydrocarbon Filtration RVCT Series RVCT Series The RVCT Series Vertical Vessels are used with Racor hydrocarbon clay elements to remove additives and surfactants from jet fuel, gasoline, kerosene and diesel. Carbon elements are used for deoiling industrial water, hydrocarbon solvents and the removal • Diesel Fuel Optional Accessories: • Pressure relief valve • Differential pressure gauge • Sampling probes • Manual drain valves • Removable bundle assembly • Inlet and Outlet: 150RF (ANSI) flanged • Main Drain: 2 inch NPT • Side Drain: 1-1/2 inch NPT •Vent and pressure relief connections: •...

Open the catalog to page 14

Hydrocarbon Filtration RVCT Series RVCT Series Overview Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 15

Hydrocarbon Filtration RVCT Series RVCT Series Overview Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 16

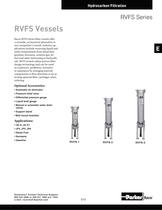

Hydrocarbon Filtration RVFS Vessels Racor RVFS Series filter vessels offer a versatile, economical alternative to any competitor's vessels. Industry ap- plications include removing liquid and solid contaminants from diesel fuel, gasoline, kerosene, aviation gas, jet fuel and other lubricating or hydraulic oils. RVFS vessels utilize proven filter design technology and can be used as coalescers, prefilterss, monitors or separators by changing internal components or flow direction or by se- lecting optional filter cartridges when Optional Accessories: • Pressure relief valve • Differential...

Open the catalog to page 17

Hydrocarbon Filtration RVFS Series RVFS Series Overview Note: Overall dimensions will vary depending on mounting leg or bulkhead method of installation. Consult factory for flow rates. Factory will require details of the application for proper sizing. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 18

Hydrocarbon Filtration RVFS Series Diesel Fuel Aviation Fuel Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 19All Parker Hannifin catalogs and brochures

-

PS120 Series

2 Pages

-

P510MAM

2 Pages

-

Boiler Layup

4 Pages

-

Wine Industry

2 Pages

-

Mechanical Gas Seals

4 Pages

-

Chemical Tank Blanketing

4 Pages

-

Power Generation

12 Pages

-

Railway Industry

8 Pages

-

Bus and Coach Products

4 Pages

-

Racor EB00007

2 Pages

-

Racor 7501

32 Pages

-

Racor 7609

8 Pages

-

Racor 7539

40 Pages

-

Racor RSL0279

2 Pages

-

Racor RSL0183

4 Pages

-

Racor 7637

2 Pages

-

Racor 7460

20 Pages

-

Racor 7815

8 Pages

-

RSL0075

12 Pages

-

Crankcase Ventilation

12 Pages

-

SNAPP Marine

1 Pages

-

Marine Filtration Systems

36 Pages

-

Snapp series

8 Pages

-

clean dry fuel

16 Pages

-

Racor Engine Air Overview Guide

40 Pages

-

Racor Marine Clean+

2 Pages

-

Bilge Adsorbent Separator

2 Pages

-

Racor Village Marine Watermakers

28 Pages

Archived catalogs

-

7807 Catalog

32 Pages

-

Additive Brochure

6 Pages

-

nofrills

2 Pages

-

BILGE WATER TREATMENT

2 Pages

-

INDUSTRIAL SERIES

2 Pages

-

WATER SERIES

2 Pages

-

Marine applications

8 Pages

-

FilterPump Brochure

2 Pages