Catalog excerpts

TYPE LSV/MSV/HSV CENTRIFUGAL FANS OPTIONAL EXECUTION Fan housing and impeller in aisi316L execution. Steel - galvanized or galvanized and painted execution are delivered on request. APPLICATIONS The centrifugal fans LSV, MSV and HSV are designed for marine use. The fans can be used for both as supply and exhaust fans. Typical applications for low and medium pressure fans are galley fans, mess room, sanitary spaces, dayroom, technical rooms etc. Often it can be used as a central with a plenum suction chamber for multiple duct connections. High pressure fans are often used for gas freeing for LPG tankers, chemical tankers etc. IMPELLERS: The impeller is as standard delivered in the same material as the fan housing, as standard salt- and ammonia resistant aluminium, dynamically balanced. The impellers are divided into four main groups: B - type: The standard impeller for the centrifugal fans. This is a cost effective impeller with high efficiency. Z – type: Self cleaning impeller, ideal for applications where dust or material in the air stream can build up on the impeller and cause imbalance. F – type: Forward curved blades (sciroccio impeller) for applications where high air flow are required. This impeller is only delivered for the smaller centrifugal fans. R – type: heavy duty impeller with radial blades for transport applications (e.g. saw dust for wood industry or similar). DESIGN The MSV / LSV / HSV fans are single inlet centrifugal fans with direct drive as standard. The design is based on three main groups, low, medium and high pressure. • LSV - Low pressure: pressures up to 3 4000Pa, capacities up to 120.000m /h with duct connection ø250 to ø1200mm. • MSV - Medium pressures up to 8.000Pa, 3 capacities up to 95.000 m /h with duct connection ø125 to ø900mm. • HSV - High pressure up to 30.000 Pa. 3 capacities up to 45.000 m /h with duct connection ø60 to ø500mm. ELECTRIC MOTOR The motors are as standard TEFC squirrel caged inductive electric motors in marine execution. Motors are IP55 and insulation class F as standard. The fans can also be equipped with EX motors for hazardous applications. Motor options: • IP56, IP65 or IP66, • anti condensing heating element • offshore painting • Vibration monitoring EXECUTION The fan housings and impeller are as standard manufactured in sea water resistant aluminium and painted. This gives a corrosion resistant fan and a spark proof design.

Open the catalog to page 1

TYPE LSV/MSV/HSV CENTRIFUGAL FANS SPECIAL DESIGNS - Belt driven execution - With gas tight motor flange (for EX applications where motor can be placed outside hazardous area) - With coupling drive - With coupling drive and cooling wheel (air cooled) for high temperature applications. - Portable execution (only smaller fans) - With water-, air- or hydraulic driven motor. PERFORMANCE Fan curves are given for standard air 1,2kg/m3 and temperature 20deg. ACCESSORIES - Vibration dampers - Flexible connections inlet/outlet - Protection grid inlet/outlet - Base frame - Motor pedestal (required for...

Open the catalog to page 2

CENTRIFUGAL FANS selection curves

Open the catalog to page 4

CENTRIFUGAL FANS selection curves

Open the catalog to page 5

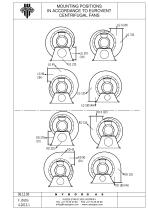

MOUNTING POSITIONS IN ACCORDANCE TO EUROVENT CENTRIFUGAL FANS LG 0 (2H) LG 315

Open the catalog to page 6

Centrifugal Fans Explanation of Fan Model Number Fan model number is stated in the following way: Centrifugal Fan model MSV 160 B1. MSV Low pressure centrifugal fan Medium pressure centrifugal fan High pressure centrifugal fan 4. -6. figure: The size of the fan. The numbers refers to nominal diameter (mm) on the fan’s suction flange. Direct driven. impeller mounted on motor shaft Belt driven. motor placed alongside the fan Belt driven. motor mounted on the fan, belt screened

Open the catalog to page 7

SOUND POWER LEVELS (SWL) CALC. NYBORG CENTRIFUGAL FANS • Sound power levels in dB. ref. 10 -12 W, internal values in fan openings. • dBA values applies to 1 m. distance based on a theoretical free field environment. • The sound power level values above are only intended as a guide, and may be used for calculations for sound pressure levels. (heard by the human ear).

Open the catalog to page 8

SOUND POWER LEVELS (SWL) CALC. NYBORG CENTRIFUGAL FANS • Sound power levels in dB. ref. 10 -12 W, internal values in fan openings. • dBA values applies to 1 m. distance based on a theoretical free field environment. • The sound power level values above are only intended as a guide, and may be used for calculations for sound pressure levels. (heard by the human ear).

Open the catalog to page 9

PAINTING SPECIFICATION ALUMINIUM FANS Surface preparation: Step No 1 Washing Cleaning Type Aluminate (acid) Water Painting : Color RAL 5012 Step No 1 Primer Topcoat Joton Washprimer Jotun Jotun Ultra Topcoat Jotun GALVANIZE SPECIFICATION STEEL FANS Surface preparation: Step No 1 Cleaning Galvanizing Type Nitric acid Zn

Open the catalog to page 10All Nyborg AS catalogs and brochures

-

DAMPERS

13 Pages

-

VENTILATION COWLS

12 Pages

-

Portable Gas Freeing Fans

10 Pages

-

Axial Flow Fans

73 Pages

-

complete catalog

382 Pages

-

MIST ELIMINATOR LOUVERS

18 Pages

-

OFFSHORE PRODUCTS APPLICATIONS

10 Pages

-

Auxiliary Blowers

3 Pages

-

Duct Fans

18 Pages