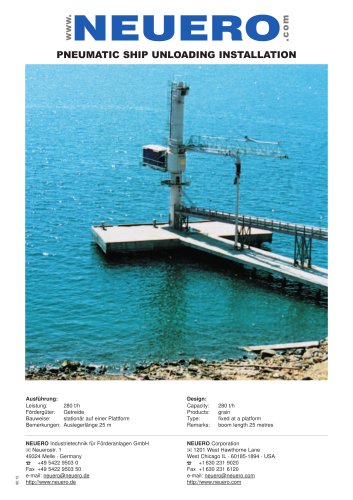

Catalog excerpts

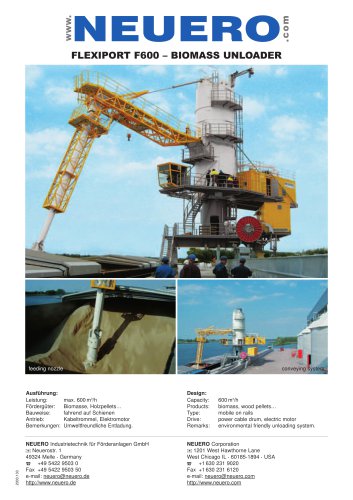

ENGINEERING & EQUIPMENT Why opt for a pneumatic system? Neuero has the answers Neuero has supplied two 600tph ship unloaders to Russia’s biggest oil extraction plant. Neuero Industrietechnik asks why it is that a system that is safe, generates the lowest noise and dust emissions, completes the job including clean-up, is highly efficient and requires lower investment is not always the first choice. The answer is simple, says Neuero. Many manufacturers do not invest in research and development, or have simply gone in the wrong direction, resulting in the loss of technical expertise. When big companies in the flour milling market do this, they argue that a pneumatic system is not the best choice. This can result in uncertainty from clients, even those that have used pneumatic systems for years. Also, some manufactures make recommendations that are based on their product offering, rather than on the best interests of the clients. Therefore, users’ decisions are made all the harder, and this can result in restrictions in the use of a system, based on erroneous assumptions. Neuero says that this situation can be rectified, by illustrating some real-life examples that illustrate technical innovations. Neuero has invested in not only a new testing and research Original blower. laboratory, but more importantly in technology. The result is a new turbo blower with direct drive. The result of the development can be seen in a reduction in energy requirements, reduction while maintaining high capacity. The energy requirement has been is the only weak point in the pneumatic unloader compared with a mechanic unloader. The power requirement gap has been reduced with the new Neuero blower direct drive compared with older pneumatic technologies. This also gives the opportunity for Neuero to be active in refurbishing less efficient existing installations. In addition to the energy reduction, reliability has also increased. The direct drive is now equipped with temperature and vibration sensors to monitor bearing conditions and provides a warning to prevent a bearing failure or notify maintenance to change it. The use of fewer parts also reduces the need for maintenance. PROJECTS In addition to new installations in Russia, Egypt, Romania, Saudi Arabia incorporating the new Neuero blower direct drives, Replacement blower

Open the catalog to page 1

ENGINEERING & EQUIPMENT Replacement nozzle. Original nozzle. Existing airlock. Neuero is also giving a second life to older installations. The first is now in Damietta, Egypt where a 30-year-old shipunloader (not made by Neuero) reached its original capacity with the new blowers and conveying adjustments, while cutting power consumption in half. Russia: two ship unloaders of 600tph (tonnes per hour) each for the biggest oil extraction plant in Russia. This is part of a third expansion at the site. Neuero has delivered two shiploaders for this project as well. Damietta: this is interesting...

Open the catalog to page 2All NEUERO Industrietechnik GmbH catalogs and brochures

-

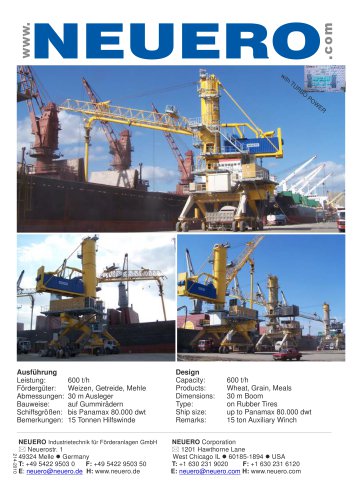

SHIP LOADER 600t/h

1 Pages

-

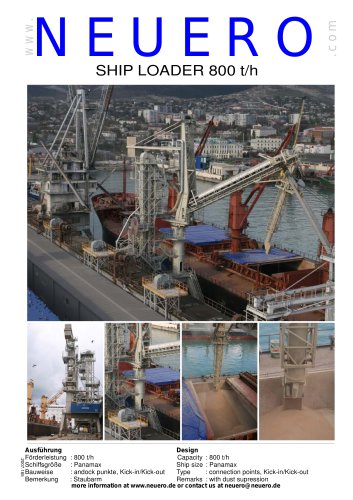

SHIP LOADER 800 t/h

1 Pages

-

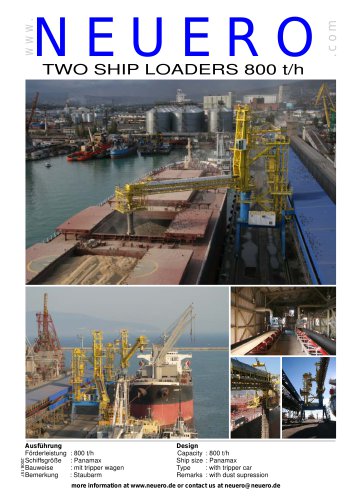

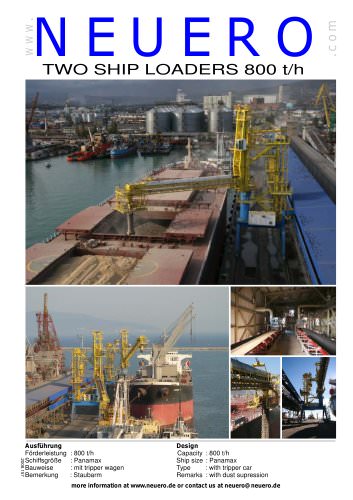

TWO SHIP LOADERS

1 Pages

-

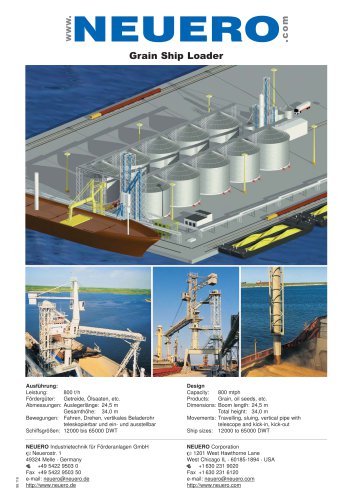

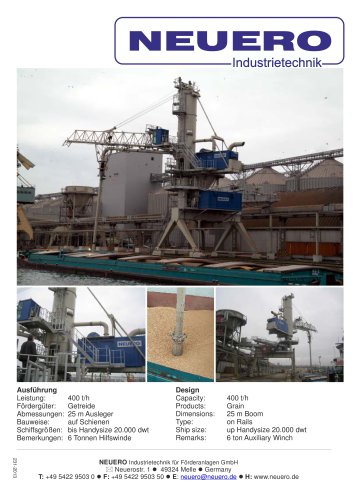

Grain Ship Loader

1 Pages

-

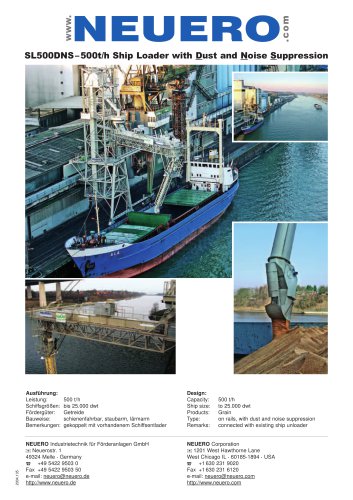

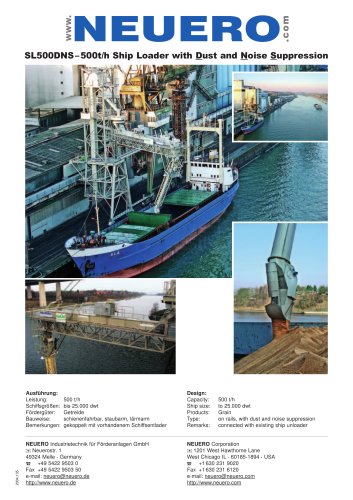

SL500DNS–500t/h S

1 Pages

-

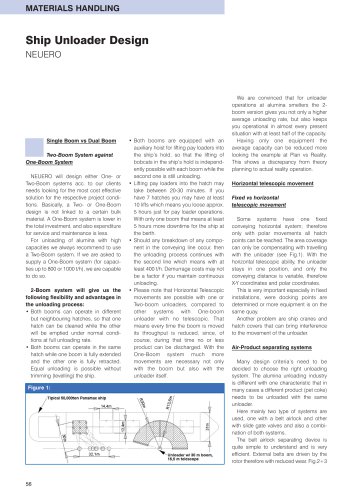

AW-Ship-Unloader-Design

2 Pages

-

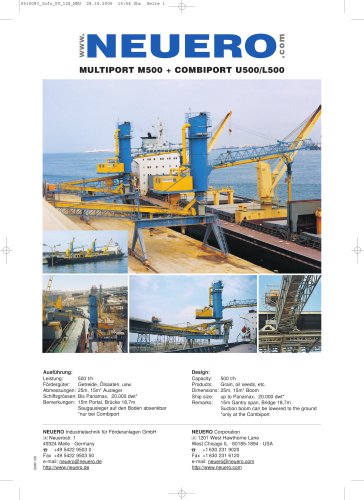

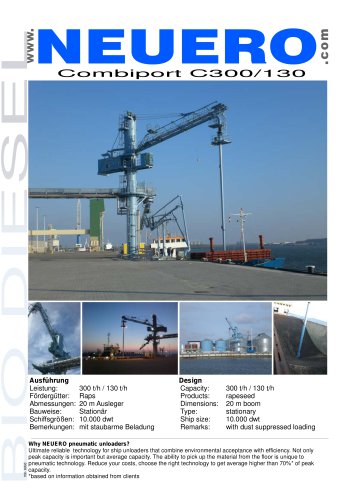

Shipunloader Multiport M400

1 Pages

-

Stationary M300

1 Pages

-

Multiport M600

1 Pages

-

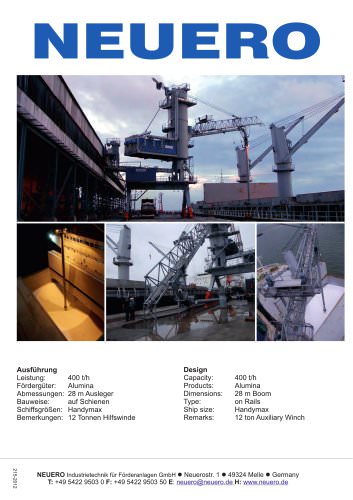

Multiport M400 for Alumina

1 Pages

-

The Netherlands 2003

1 Pages

-

Multiport M400

1 Pages

-

MULTIPORT GF GS 300 t/h

1 Pages

-

Multiport M300

2 Pages

Archived catalogs

-

SHIP LOADER : 500 t/h

1 Pages

-

SHIP LOADERS 180 tph grain

1 Pages

-

tower

1 Pages

-

MULTIPORT on rails

1 Pages

-

STATIONARY SHIPUNLOADER

1 Pages