Catalog excerpts

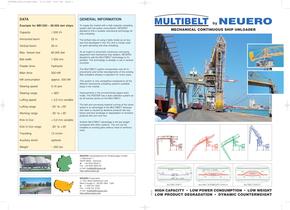

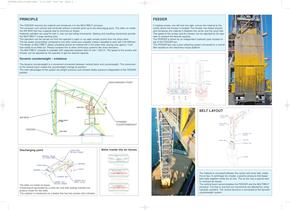

Horizontal boom Vertical boom Belt width Feeder drive Main drive Slewing speed Slewing range Luffing speed Luffing range Working range Kick In-Out Kick In-Out range Auxiliary winch GENERAL INFORMATION To supply the market with a high capacity unloading system with low power consumption, NEUERO decided to find a suitable mechanical technology for ship unloading. The brilliant idea of using 2 belts inside an air box was first developed in the 70's and is mostly used for grain elevating and ship unloading. As an expert in pneumatic continuous conveying equipment and mechanical ship loaders, NEUERO decided to add the MULTIBELT technology to it's portfolio. This technology is already in use in several The MULTIBELT system incorporates now all im- provements and further developments of the existing Belt unloaders already in operation for many years. This system is very competitive compared to all the different mechanical unloading systems available Improvements in the environmental aspect were made. The FEEDER has a dust collection system as do all transfer points on the MULTIBELT. The belt and conveying material running at the same speed is an advantage of the MULTIBELT because less wear is caused by abrasive products like soy- beans and less breakage or degradation of sensitive products like corn and rice. Another MULTIBELT advantage is the low weight compared with other systems. The unit can be installed on existing piers without need of reinforce- NEUERO Industrietechnik für Förderanlagen GmbH NEUERO Corporation E*a 1201 West Hawthorne Lane e-mail: multibeltOneuero.com MULTIBELT NEUERO MECHANICAL CONTINUOUS SHIP UNLOADER CARRIER BELT CARRIER BELT - RETURN MULTIBELT EMPTY MULTIBELT INTERMEDIATE CAPACITY MULTIBELT CAPACITY HIGH CAPACITY • LOW POWER CONSUMPTION • LOW WEIGHT LOW PRODUCT DEGRADATION • DYNAMIC COUNTERWEIGHT

Open the catalog to page 1

The FEEDER receives the material and introduces it to the MULTIBELT conveyor. The conveyor runs vertical and horizontal without a transfer point up to the discharging point. The belts run inside the AIR BOX that has a special seal to minimize air losses. Hydraulic cylinders are used for kick in, kick out and luffing movements. Slewing and travelling movements provide the MULTIBELT a large working area. The operation can be carried out from the operator's cabin or via radio remote control from the ship's deck. The low power consumption compared to any other continuous unloader makes it...

Open the catalog to page 2All NEUERO Industrietechnik GmbH catalogs and brochures

-

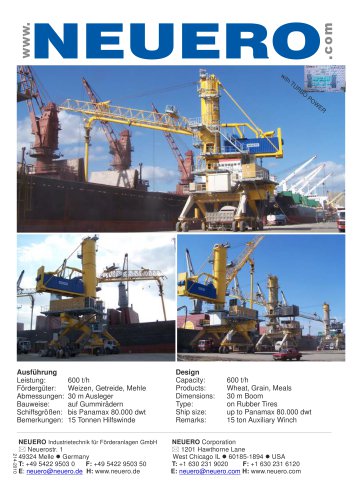

SHIP LOADER 600t/h

1 Pages

-

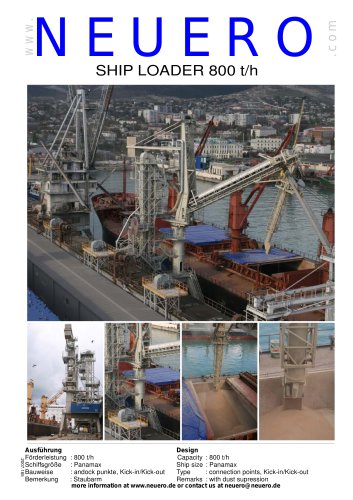

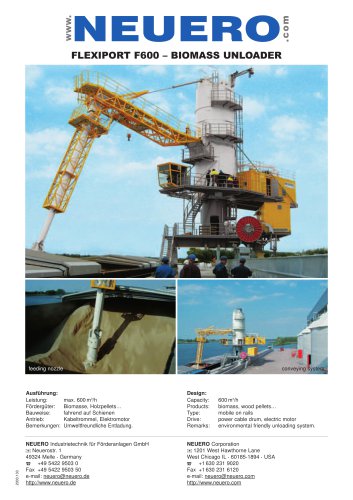

SHIP LOADER 800 t/h

1 Pages

-

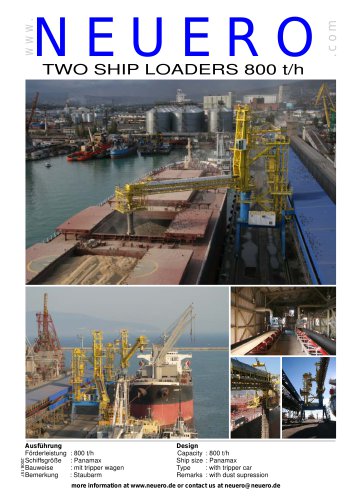

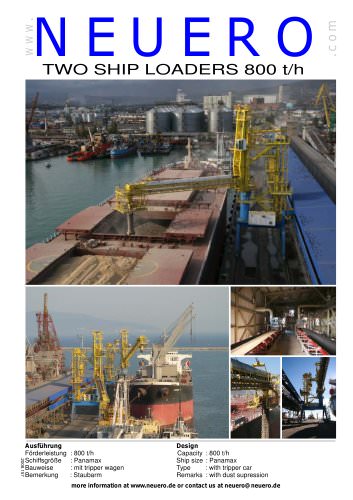

TWO SHIP LOADERS

1 Pages

-

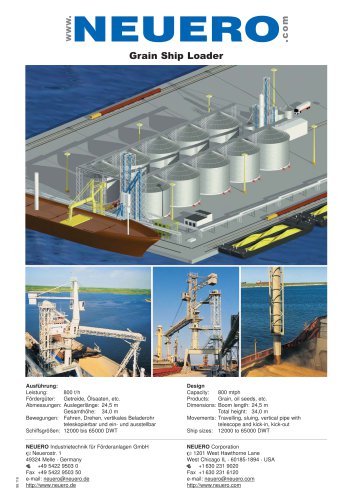

Grain Ship Loader

1 Pages

-

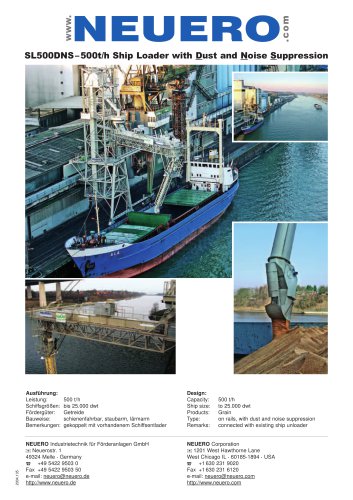

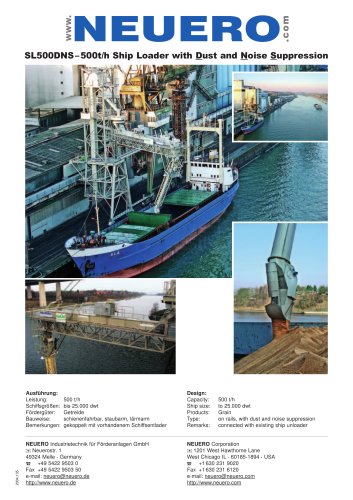

SL500DNS–500t/h S

1 Pages

-

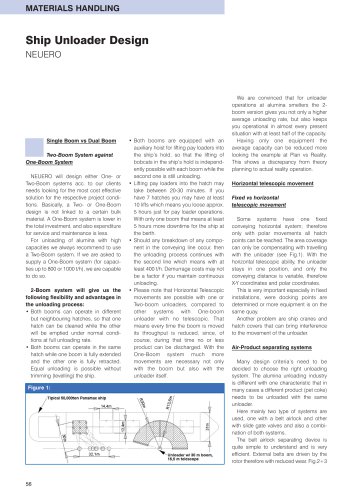

AW-Ship-Unloader-Design

2 Pages

-

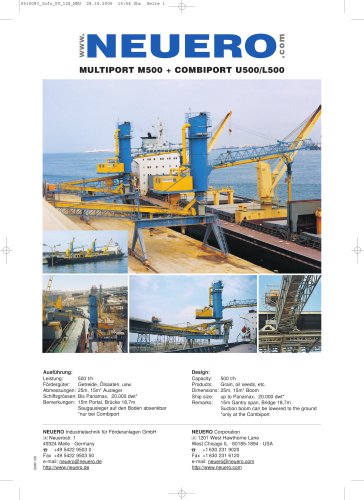

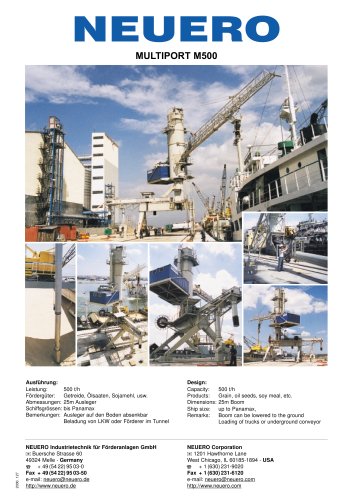

Shipunloader Multiport M400

1 Pages

-

Stationary M300

1 Pages

-

Multiport M600

1 Pages

-

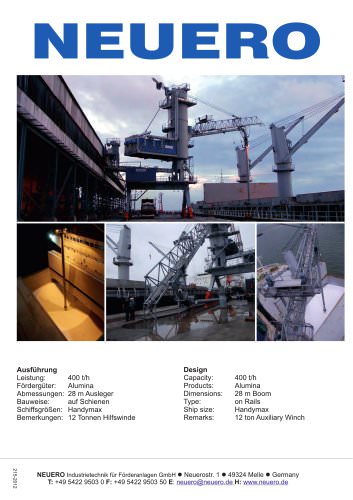

Multiport M400 for Alumina

1 Pages

-

The Netherlands 2003

1 Pages

-

Multiport M400

1 Pages

-

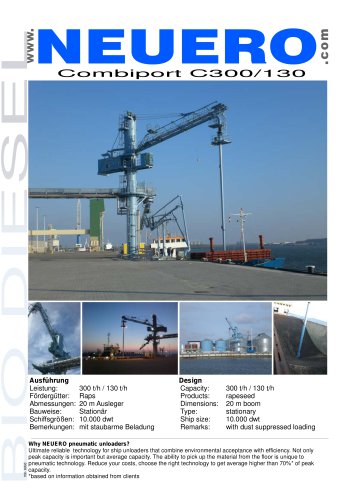

MULTIPORT GF GS 300 t/h

1 Pages

-

Multiport M300

2 Pages

Archived catalogs

-

SHIP LOADER : 500 t/h

1 Pages

-

SHIP LOADERS 180 tph grain

1 Pages

-

tower

1 Pages

-

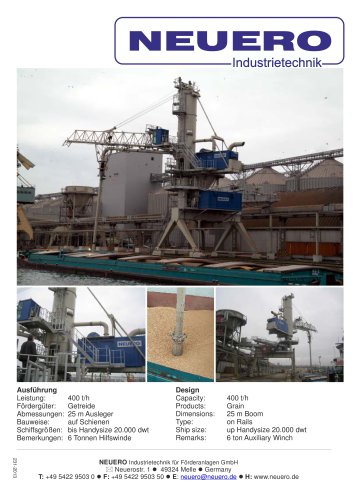

MULTIPORT on rails

1 Pages

-

STATIONARY SHIPUNLOADER

1 Pages