Catalog excerpts

ENGINEERING & EQUIPMENT Dust emission control with NEUERO’s dust suppression head Fig. 2 Fig. 1 and Fig. 2: NEUERO dust suppression head used in an installation for ammonium sulfide in Germany. EXAMPLES Depicted in Fig. 1 and Fig. 2 is an installation for ammonium sulfide in Germany. The parts in contact with the product are made of stainless steel. The NEUERO dust suppression head is not only applicable in new installations but also in existing installations. Below the case at Nibulon Grain Terminal in Nikolayev – Ukraine. The same system, but in a different size, Fig. 3 and Fig. 4 shows 800 tonnes per hour loading spouts with Fig. 1 40m long reach. They were in the past as shown in Fig. 5, but the dust and wear was high. The combination of dust suppression and pipes made of Hardox 450 ensures the longevity of the loading pipes. FUNCTION NEUERO’s dust suppression head’s funtioning is relatively simple, has low material speed and constant material column. The head, by opening and closing, only allows material to flow slowly, not letting the air carry the dust to the atmosphere. The front valve opens when a material column is built and close it when the material column is reduced. The software can be adapted by different products optimizing the system. Fig.5 Example of past loading spouts. Fig.3 (above) and Fig.4 (below) shows 800tph loading spouts with 40m long reach.

Open the catalog to page 1All NEUERO Industrietechnik GmbH catalogs and brochures

-

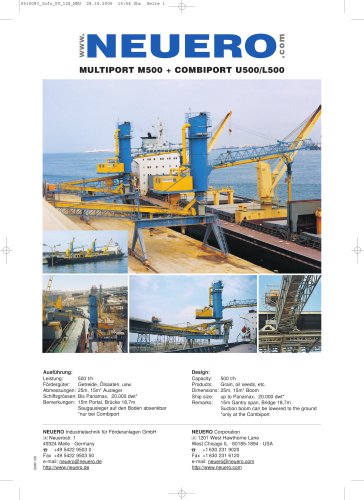

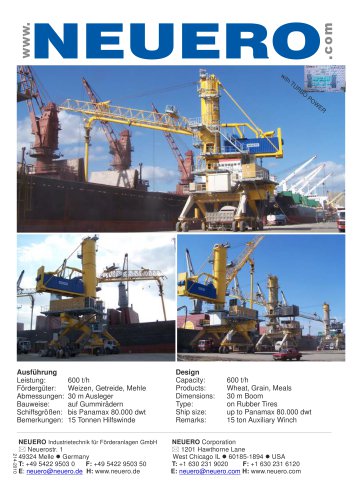

SHIP LOADER 600t/h

1 Pages

-

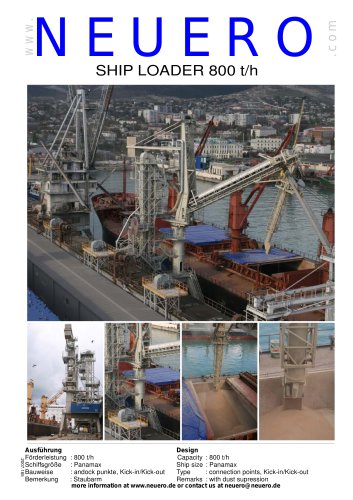

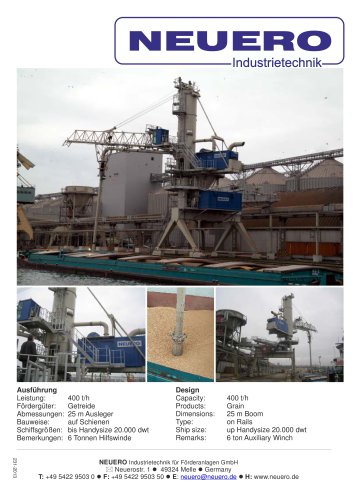

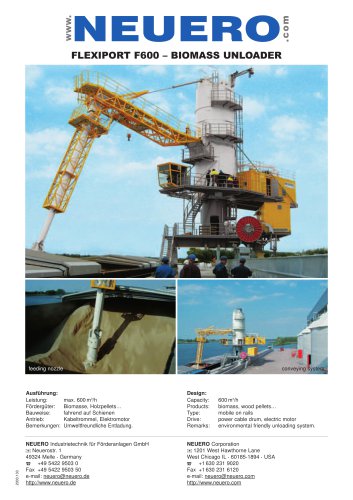

SHIP LOADER 800 t/h

1 Pages

-

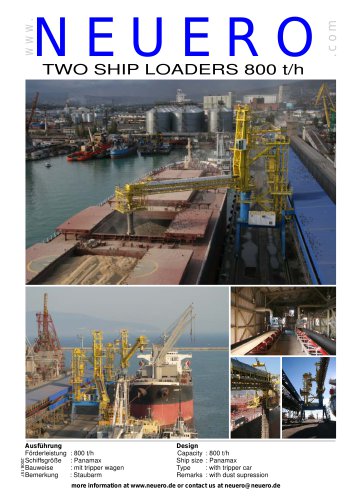

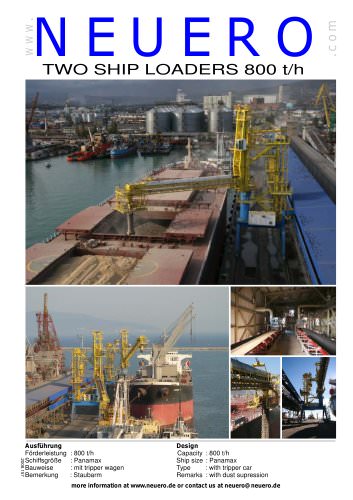

TWO SHIP LOADERS

1 Pages

-

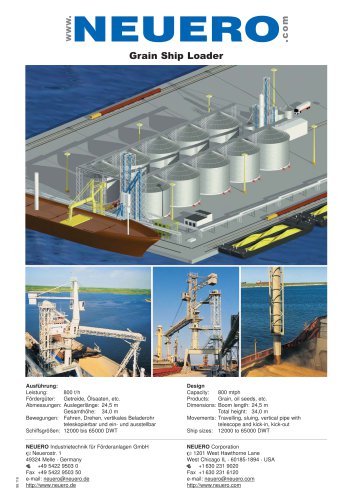

Grain Ship Loader

1 Pages

-

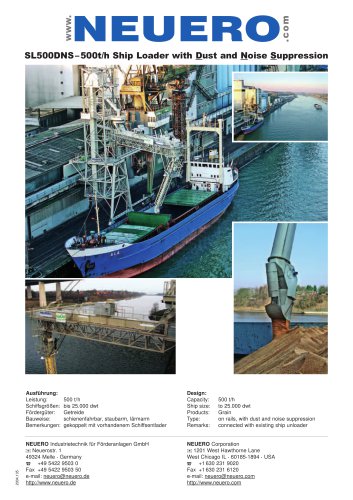

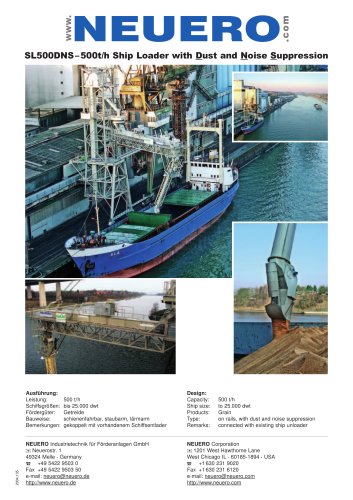

SL500DNS–500t/h S

1 Pages

-

AW-Ship-Unloader-Design

2 Pages

-

Shipunloader Multiport M400

1 Pages

-

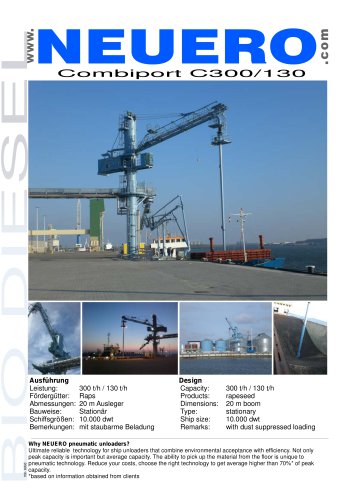

Stationary M300

1 Pages

-

Multiport M600

1 Pages

-

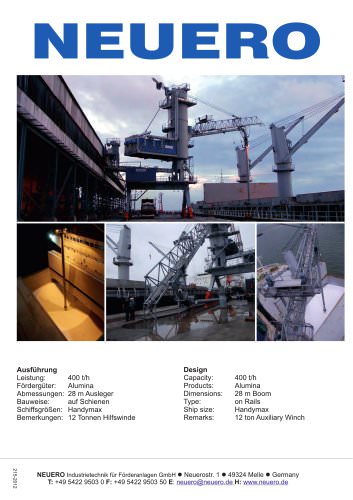

Multiport M400 for Alumina

1 Pages

-

The Netherlands 2003

1 Pages

-

Multiport M400

1 Pages

-

MULTIPORT GF GS 300 t/h

1 Pages

-

Multiport M300

2 Pages

Archived catalogs

-

SHIP LOADER : 500 t/h

1 Pages

-

SHIP LOADERS 180 tph grain

1 Pages

-

tower

1 Pages

-

MULTIPORT on rails

1 Pages

-

STATIONARY SHIPUNLOADER

1 Pages