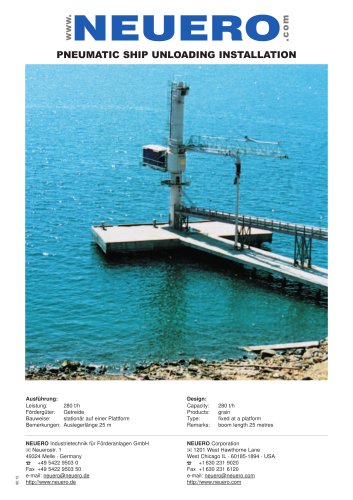

Catalog excerpts

SPECIAL Ports & Terminals The Efficiency of Continuous Ship Unloaders T. Kisslinger, Germany Nowadays, CSUs a widely accepted as a good alternative to grab type unloaders. But there’s more than one type of CSU available on the market, and choosing the right type for your application can make the difference. his paper compares the use of pneumatic and mechanical unloaders mainly for grain. Therefore, it gives a brief overview of what options are available in the market, but also goes into more detail with a comparison between chain type mechanical vs. pneumatic unloaders. Average Capacity Maximum Capacity Efficiency = _______________ The goal is to develop an unloader that achieves higher performance by increasing the average capacity, therefore making better use of the complete installation. The ideal case would be Average = Maximum, but this is impossible to achieve due to a series of variables, including some of which that are not even equipment related, including rain delays or the amount of visits to each hatch for ship stability. Developments in Pneumatic CSUs The development of software which uses frequency inverters to control turbo blower rotation speed has resulted in a more constant capacity during operations. It has also increased the ability to control the unloaded capacity. This helps, when materials with different specific weights are unloaded or capacity needs to be adjusted to match receiving conveyors. By traditional design the boom should reach the centre of the hatch to achieve ship stability. However, a longer boom would allow one to reach the hatch corners resulting in the need to move less material with payloaders, while bigger payloaders for the clean up work would also help. With these measurements, it is possible to achieve 75 per cent capacity with pneumatic unloaders. As you can see, it is not only the unloader itself but all of the receiving conveyors which determine the maximum capacity of the system; i.e. the system is only as strong as the weakest link in the chain. CSU principles The principle of CSU is to avoid peak unloading by distributing materials in time at the receiving conveyors. CSU types The main CSU groups are mechanical and pneumatic. The mechanical group can be divided into belt, screw, chain and bucket conveying types. Comparison of Continuous and Discontinuous Unloading CSUs are normally compared with a traditional grab batch unloading system. The grab capacity is calculated on the basis of the movement cycle. A buffer is needed to distribute the material load along the cycle, avoiding extreme peaks. A CSU does not need a buffer because the peak is not distributed in time cycles, but instead it is continuously transporting the material. The consequence of this is normally a lower weight and the fact that operations are environmentally friendly enclosed. The Difference Between Chain and Pneumatic Unloaders A regular chain unloader is used in the same application as a pneumatic unloader because they do not have a feeder, but use a free flowing characteristic to feed the unloader instead. However, this is where the similarities end. The pneumatic unloader is the only CSU that picks up material from the bottom of the hatch. Fig. 1a) and Fig. 3 show that it is able to act like a vacuum cleaner, and remove all products from the hatch. bulk solids handling · Vol. 27 ·

Open the catalog to page 1

5Fig. 1: Part a) of this figure shows the nozzle reaching the bottom of the hatch and picking the material. Part b) shows that the chain needs a column of product around it to be filled and that a safety distance to the hatch bottom is necessary to avoid collision. The chain, however, relies on product pressure to introduce the material into the chain through. The product pressure depends on the product column around the entry point. As depicted in Fig. 1b), the material height is shown as h1 while the remaining height which does not to hit the bottom of the hatch is shown as h2. This can...

Open the catalog to page 2

SPECIAL Ports & Terminals Also the method of unloading, (moving five or, respectively, nine times into the same hatch), means that the total number of times each hatch must be visited influences the average capacity and also the geometry of the equipment. The design characteristic of the chain system makes it difficult to achieve better average capacities, especially when only one unloader is available and no pneumatic system is available. In many cases portable pneumatic units are used to get better results, although they increase the operating cost. Which Capacity? There are numerous...

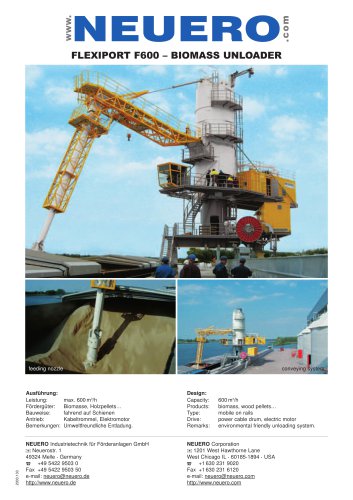

Open the catalog to page 3All NEUERO Industrietechnik GmbH catalogs and brochures

-

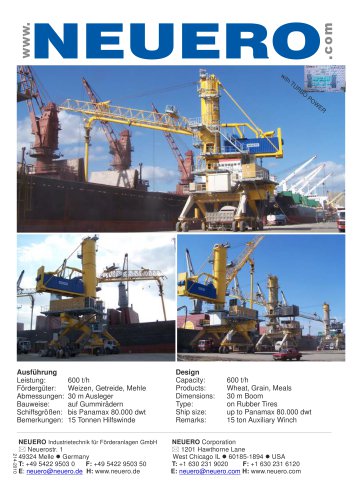

SHIP LOADER 600t/h

1 Pages

-

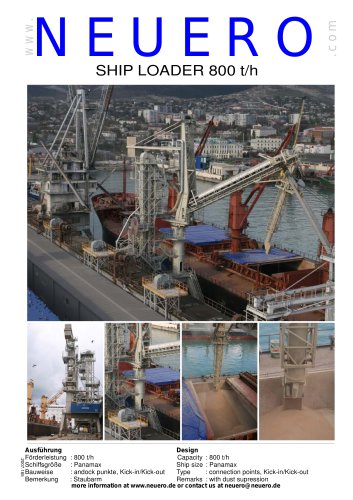

SHIP LOADER 800 t/h

1 Pages

-

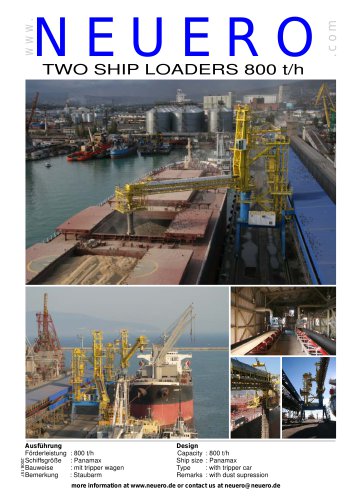

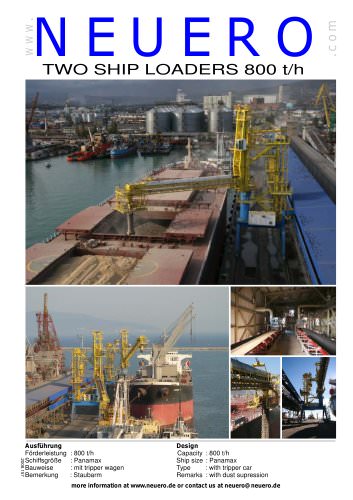

TWO SHIP LOADERS

1 Pages

-

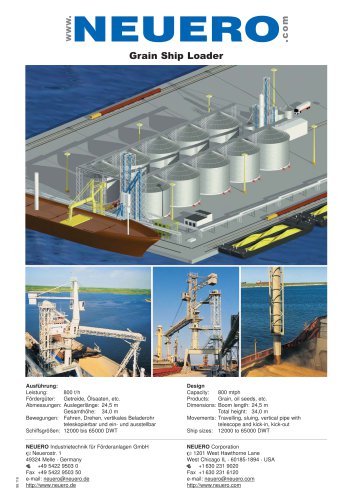

Grain Ship Loader

1 Pages

-

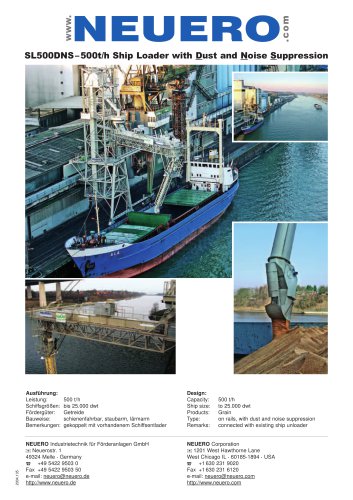

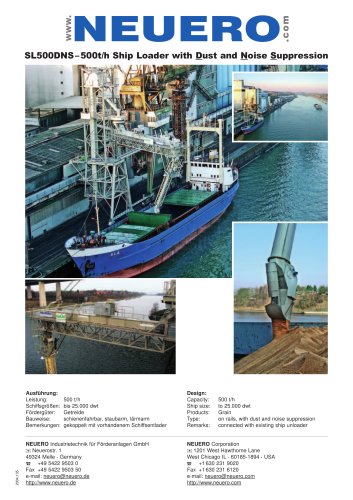

SL500DNS–500t/h S

1 Pages

-

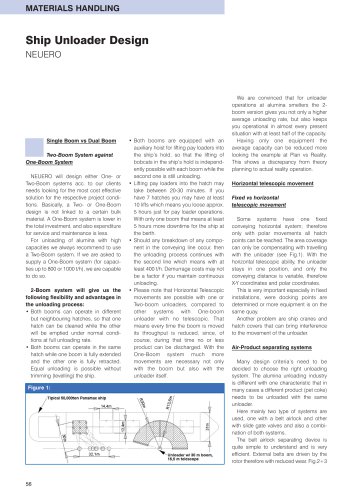

AW-Ship-Unloader-Design

2 Pages

-

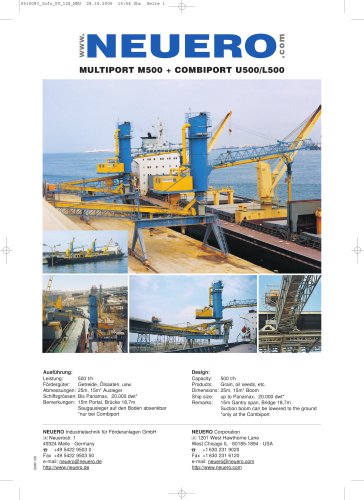

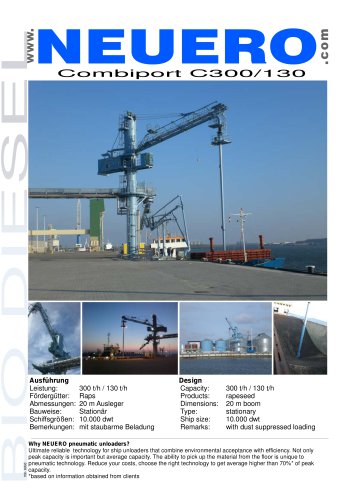

Shipunloader Multiport M400

1 Pages

-

Stationary M300

1 Pages

-

Multiport M600

1 Pages

-

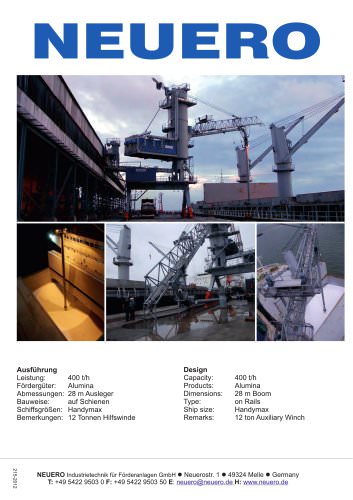

Multiport M400 for Alumina

1 Pages

-

The Netherlands 2003

1 Pages

-

Multiport M400

1 Pages

-

MULTIPORT GF GS 300 t/h

1 Pages

-

Multiport M300

2 Pages

Archived catalogs

-

SHIP LOADER : 500 t/h

1 Pages

-

SHIP LOADERS 180 tph grain

1 Pages

-

tower

1 Pages

-

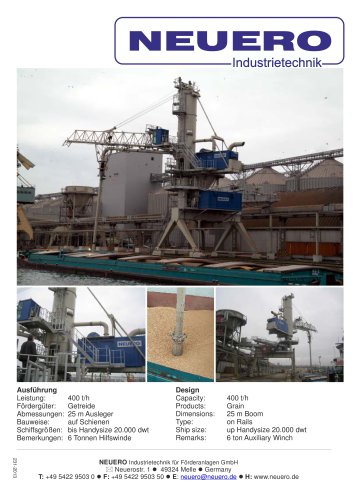

MULTIPORT on rails

1 Pages

-

STATIONARY SHIPUNLOADER

1 Pages