Catalog excerpts

processing and design tips Metawell Klimadecke

Open the catalog to page 1

c o n t ents page Edge forms • Edge designs • Border finishes • Tool parameters • Tool parameters Slit cutter Prismatic cutter Individual colouring

Open the catalog to page 2

Ed g e f orms Edge designs Metawell® offers other possibilities for edge finishes than sheet metal, which is due to its specific panel structure. More significant characteristics can be created at the edge of a sandwich panel by use of an application-matching edge design: • optical adjustment of the edge to the application • increase of the element‘s stiffness in the edge areas • reduction of the risk of injuries caused by sharp metal edges • reduction of assembly work by „automatic“ fitting e.g. by integrated drill holes for connectors • concealed attachment of profiles and fittings at the...

Open the catalog to page 3

metal sandwich technology Design BK (sheet covered edge) Radius: approx. 1 mm •y/yy v/v/v7T^ Design EP/S (hammer shear cut edge) '\/\/\/\/YTT7> Design EP/D (cover sheet pressed) Modifications and errors reserved Edge design BK Use: Tool: Particularity: ceiling elements, linings, doors, covers CNC-work station can also be realized with coil-coated panels Edge design EP/S Use: ceiling elements, linings Tool: rotary jars Particularity: ideally suited for coil-coated panels (no cuttings) Edge design EP/D Use: gapless ceilings, big joint-less surfaces Tool: CNC-work station...

Open the catalog to page 4

Border finishes Plastic beading Edge profile Glued insert Besides foldings many other border finishes are possible with Metawell® panels. When choosing an appropriate finish the following aspects should be considered: • Optical requirements (design, type of surface) • General constructional conditions (flush connection to the panel surface, fixing of accessories or connection with other elements) • Ambiant parameters (temperature, pressure, affecting media) • Load on the borders during operation (mechanic stress, thermal loads, type of element – mobile or fixed mounting) • Requirements with...

Open the catalog to page 5

Specifications /\/\/\/ \/\/\/\ Blind rivet - concealed fixing Blind rivet - throughgoing 7\/\ / \ / \ill /' \ / \ /\TT j v> \j \j aa \j \j v>r Blind rivet - riveting in double panel Meta well metal sandwich technology Metawell® panels can be connected to each other or to other materials by conventional rivets. The rivets' length and diameter depend mainly on the combination of the components involved. The core structure of Metawell® also allows concealed riveting on one side. The use of blind rivets enables the visible surfaces to be mechanically secured without detracting from their visual...

Open the catalog to page 6

Specifications Tool parameters Source of supply Modifications and errors reserved Meta well metal sandwich technology Metawell® can be worked with circular, jig and band saws with conventional saw blades: dihedral saw blades should not be used, however, since the teeth may become entangled between the cover sheet and the corrugation producing an unclean cut. Flat trapezoidal teeth with a negative tooth position and hard metal cutting edges have proven ideal when using circular saws. A format-cutting sliding table or the use of vertical saws is advantageous when processing large panels. For...

Open the catalog to page 7

metal sandwich technology MILLING AND DRILLING Specifications Metawell® panels can be processed with hand tools and machine tools. Wood-working tools are ideal, especially if equipped with the relevant protection device against metal cuttings, since processing Metawell® is more closely related to processing wood than to processing metal. This refers particularly in terms of the large surface area, the clamping techniques, the feed speed and the lack of requirement for coolants and lubricants. In addition, the usability of the existing suction device must be checked in advance. In addition,...

Open the catalog to page 8

Metawell® panels, as e.g. the panel type Alu CC 08-02-05 / H6 which is frequently used in interior constructions, can be plastically shaped around one axis with appropriate devices. The forming process creates tensile strain in one cover sheet of the panel and crushing strain in the opposite cover sheet. The loading direction has also an influence on the panel, which is due to the fact that the core of Metawell® panels is a corrugated sheet: • When bending parallel to the corrugation tops, the cover sheet which is under crushing strain may buckle between the corrugation peak. Therefore only...

Open the catalog to page 11

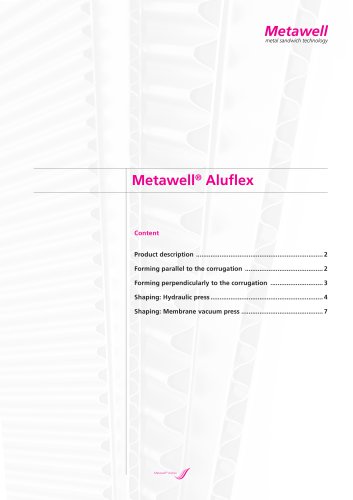

Metawell® Aluflex Fig. 1: Transformation parallel to the corrugation tops Metawell® Aluflex consists of a thin corrugated aluminium sheet that is glued to one flat cover sheet. This makes for a panel that is very flexible in one direction but rigid in the other, which is ideal for formed structures. Forming parallel to the corrugation Thanks to its special structure Metawell® Aluflex can be very easily transformed around the axis parallel to the corrugation tops, with smaller bending radii (e.g. for Metawell® Aluflex 05-02 / H4.7 smaller than 200 mm) even plastically (see fig. 1). The...

Open the catalog to page 12

I n d i vidual col ouring Painting Thanks to their even surfaces Metawell® panels are particularly suited as design material for surfaces that have to meet high demands regarding their visual effect. With the multiple possibilities there are some important aspects which have to be considered: • The maximum temperature the panels can be exposed to is 100° C. Higher working temperatures might be tolerable for special paint procedures, but must be verified by the plant. • To receive an optically even surface the minimum thickness of the cover sheet (visible side) should not be less than 0.8...

Open the catalog to page 13

Because of its flat surface Metawell® panels are an ideal substrate for a variety of coatings. However, basic aspects have to be considered: • The maximum temperature the panels can be exposed to is 100° C. Higher working temperatures may be possible on request. • When selecting a coating the different expansion coefficients of panels and coating material must be taken into account. Preliminary tests should always be carried out to check the suitability of the selected combined system. Filler and plaster coatings In principle, any fillers suitable for metal substrates, such as those used in...

Open the catalog to page 14All Metawell GmbH- metal sandwich technology catalogs and brochures

-

Metawell® data sheets

11 Pages

-

Metawell® Aluflex

9 Pages

-

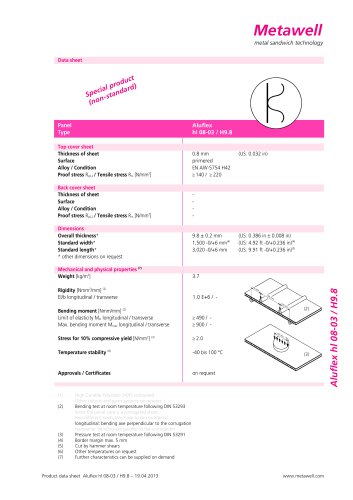

Aluflex hl 08-03 hl / H9,8*

1 Pages

-

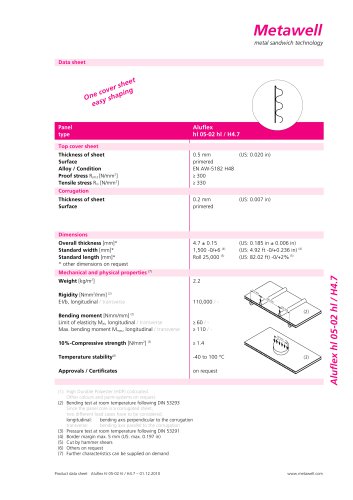

Aluflex hl 05-02 hl / H4,7

1 Pages