Catalog excerpts

MORDEC designs & manufactures top quality Hull Fittings, Towing & Mooring Gears and ™ Buoy Systems for shallow to deep sea moor or bottom mounted instrument structures. Most Hull Fittings produce in accordance to JIS & OCIMF Standards inclusive of test & third party certification upon requests requests. MORDEC Wire Ropes

Open the catalog to page 1

MORDEC™ WIRE ROPES With our extensive market reach and rigging unit that conforms to the best practices and highest quality systems, we have successfully serviced the marine, offshore, engineering, construction, fishing, cranes, and the mining industries. MEP stocks a wide range Steel Wire Ropes from UK, Korea, India, China, Malaysia, and Japan that are manufactured with state of art technology and ISO 9001 certified. Our wire ropes stock in different constructions and range from 6mm to 114mm. The types are catered for Marine, Offshore, Multi-strand Crane Ropes “compact & plastic filled”,...

Open the catalog to page 2

MORDEC™ WIRE ROPES MORDEC Testing and Certification Centre MORDEC Testing and Certification Centre (MORDEC T&C) was established in Singapore and licensed by MORDEC Innovative Solutions (UK) Co., Ltd (MORDEC UK) to conduct testing and certification of materials handling and lifting gears. It offers a comprehensive program to ensure all gears and slings sent to the centre are tested, inspected and certified accordance to the technology, methodology and procedure commissioned by MORDEC UK. Beside offering the testing and certification, MORDEC T&C is able to produce and assemble all types of...

Open the catalog to page 3

Traditionally, wire rope inspection has multiple weakness, visual and hand-touch inspection detects only visible and exterior problem and quantitative inspection of wire rope has always been a problem, electromagnetic inspection technology is also hard to adapt due to technical limitation such as weight, poor anti-interference, inaccurate test MEP Systems adopted Mordec wire rope non-destructive technique: WEAK MAGNETIC INSPECTION is the latest known technology in wire rope inspection to detect interior defect such as broken wire, abrasion, corrosion and most importantly material fatigue....

Open the catalog to page 4

MORDEC WIRE ROPES 6 X 19 + FC Steel Wire Ropes ♦ Designed for Crane, Hoist, Construction and General Engineering application ♦ Most economical design for applications requiring large diameters ♦ Strong resistance to abrasion ♦ 6 strands with 19 wires per strand configuration

Open the catalog to page 5

6 X 24 + FC Steel Wire Ropes ♦ Designed for Marine and Engineering application ♦ Strong resistance to abrasion ♦ 6 strands with 24 wires per strand configuration

Open the catalog to page 6

MORDEC™ WIRE ROPES 6 X 37 + FC Steel Wire Ropes WIRE ROPES

Open the catalog to page 7

MORDEC WIRE ROPES 6 X 37 + IWRC Steel Wire Ropes ♦ Designed for Crane, Hoist, Construction and General Engineering application ♦ Strong resistance to abrasion ♦ Independent wire rope core ♦ 6 strand with 37 wires per strand configuration

Open the catalog to page 8

MORDEC WIRE ROPES Steel Wire Ropes ♦ Designed for Crane, Hoist, Construction and General Engineering application ♦ Strong resistance to abrasion ♦ Independent wire rope core ♦ 6S Strand with 19,25,26 wires per strand

Open the catalog to page 9

MORDEC WIRE ROPES 6X19 + IWRC Steel Wire Ropes ♦ Designed for Crane, Hoist, Construction and General Engineering application ♦ Strong resistance to abrasion ♦ Independent wire rope core ♦ 6 strand with 19 wires per strand configuration

Open the catalog to page 10

MORDEC WIRE ROPES 6 X 36 + IWRC Steel Wire Ropes ♦ Designed for Mooring, Hedry Derrick Hoist Ropes, ♦Towing and General Engineering application Strong resistance to abrasion ♦ Independent wire rope core ♦ 6 strand with 36 wires per strand configuration

Open the catalog to page 11

MORDEC WIRE ROPES (2)19 X 7 Steel Wire Ropes ♦ Designed to minimize rotation of ropes when hanging loads ♦ Strands laid in opposite directions

Open the catalog to page 12

MORDEC™ WIRE ROPES Crane Ropes - Cranemaster® 8P Constructions 8PIxK26SW (10-5+5-5-1)-CWR • Cranemaster® 8P is a high strength eight strand rope with plastic impregnated core ideal for situations where longer service life is required. • High fatigue life resulting from the unique compaction process. • Maximum resistance to crushing. Recommended for multi layer spooling operations. • Increased abrasion resistance resulting from the unique compaction process. • Greater surface contact area resulting from the eight strand construction and compacted finish give longer rope life and reduce...

Open the catalog to page 13

MORDEC™ WIRE ROPES Crane Ropes - Cranemaster® 35/35P Constructions 35xK7 (16xK7: 6xK7-6xK7-1x7) • Cranemaster® 35/35P has the highest Strength of all low rotation hoist ropes. • A sample of rope from each production batch is tested to destruction in order to confirm compliance with catalogue breaking force values. • Maximum resistance to rotation. • Suitable for use on single part and multi-part hoist reeving system. • High fatigue life resulting from the unique compaction process. • Increased resistance to crushing. Recommended for multi-layer spooling operations. • Increased abrasion...

Open the catalog to page 14

MORDEC™ WIRE ROPES BS 464 Heavy Duty Thimble Groove Width Outside Length 8 mm 51 mm 10 mm 64 mm 76 mm 12 mm 14 mm 89 mm 16 mm 102 mm 18 mm 114 mm 20 mm 127 mm 140 mm 22 mm 152 mm 24 mm 28 mm 178 mm 32 mm 203 mm 229 mm 36 mm 254 mm 40 mm 44 mm 279 mm 305 mm 50 mm WIRE ROPES Groove Width Outside Width 9 mm 40 mm 11 mm 50 mm 60 mm 13 mm 70 mm 16 mm 18 mm 80 mm 90 mm 20 mm 100 mm 22 mm 24 mm 110 mm 26 mm 120 mm 29 mm 130 mm 31 mm 140 mm 160 mm 35 mm 40 mm 180 mm 200 mm 44 mm 220 mm 48 mm 53 mm 240 mm 57 mm 260 mm

Open the catalog to page 15

MORDEC™ WIRE ROPES Closed Type Galvanised Steel Spelter Sockets Open Type Galvanised Steel Spelter Sockets

Open the catalog to page 16

MORDEC™ WIRE ROPES WIRE ROPES US Type Mooring Socket

Open the catalog to page 17

MORDEC™ WIRE ROPES Two-leg bridle sling 0˚ to 45˚ Three and four-leg bridle sling 0˚ to 45˚ 46˚ to 60˚ Working Load Limit (Safety Factor 5:1) 1.10 T 0.70 T 1.55 T 1.05 T 1.40 T 2.00 T 1.30 T 0.95 T 2.40 T 1.70 T 1.60 T 1.15 T 3.00 T 2.12 T 1.40 T 2.00 T 2.50 T 1.70 T 3.55 T 2.30 T 3.00 T 2.00 T 4.15 T 2.80 T 3.40 T 4.80 T 3.15 T 2.25 T 4.50 T 6.30 T 4.20 T 3.00 T 7.80 T 5.65 T 3.70 T 5.20 T 6.90 T 9.80 T 4.60 T 6.50 T 8.40 T 5.65 T 11.80 T 7.80 T 10.00 T 14.00 T 6.70 T 9.40 T 11.50 T 16.50 T 11.00 T 7.80 T 19.00 T 13.50 T 9.00 T 12.50 T 17.50 T 11.80 T 25.00 T 16.50 T 22.50 T 31.50 T 15.00...

Open the catalog to page 18All MEP Systems catalogs and brochures

-

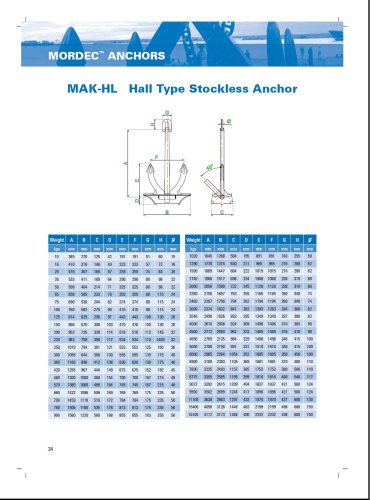

MAK-TW

1 Pages

-

MAK-SP

1 Pages

-

MAK-DF

1 Pages

-

MAK-AC

1 Pages

-

MAK-HL

1 Pages

-

Cargo securing equipment

7 Pages

-

MORDEC? Anchors

14 Pages

-

MORDEC? Anchor Chain & Fittings

22 Pages

-

SHACKLES

7 Pages

-

MORDEC? Hull Fittings

26 Pages

-

MORDEC? Synthetic Ropes

10 Pages

-

Hose Reel

1 Pages

-

Spooler

1 Pages

-

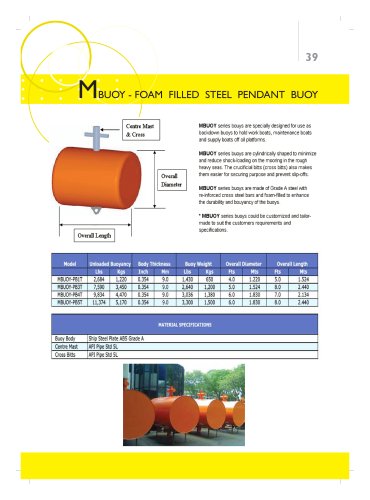

M-Buoy

1 Pages