Catalog excerpts

MANUAL TYPE MATERIAL HANDLING EQUIPMENT The following information is of a general nature covering universal safety guidelines on the use and maintenance of manual operated material handling devices such as chain block, lever hoist, trolley, and lifting clamp. The accident prevention act and safety regulations of the respective country for using such devices must be strictly adhered to. In order to ensure safe and reliable operations, the conditions for inspection and maintenance must be complied with in addition to safety instructions. Due care and diligence should be exercised when...

Open the catalog to page 2

SAFETY INFORMATION FOR LEVER HOIST Lever hoist is used for pulling and tensioning of loads. The capacity indicated on the identification plate is the Working Load Limit (WLL) that may be utilized. Lever hoist should only be operated by a trained person who is familiar with the operating and safety procedure. Improper operation of lever hoist may cause dangerous situations which may result in injuries or death. All operating instructions must be strictly followed and full inspection by a trained person must be conducted before and after any operation. 1. Adjustment of Chain Length by Free...

Open the catalog to page 3

SAFETY INFORMATION FOR CHAIN BLOCK Manual Operated Chain block is used as a portable device for lifting and moving of load and is especially useful in areas where power supply is not available. It may also be attached to a trolley for use on overhead rail systems for easy moving of load. The capacity indicated on the identification plate is the Working Load Limit (WLL) that may be lifted. Chain blocks should only be operated a by trained person who is familiar with the operating and safety information. All operating instructions must be strictly followed and full inspection by a trained...

Open the catalog to page 4

WARNING: Safety Guidelines To Be Observed At All Times During Operation ♦ Do not exceed the rated capacity of Working Load Limit of the hoist ♦ Do not lift or move people using the hoist ♦ Do not perform modification or welding on hooks or load chain ♦ Load chain must not be used separately for lifting or lashing of load ♦ Avoid side pulling when using chain block. All pull direction should be vertical only ♦ Do not tie knots, shorten, bend or twist the load chain using any devices including bolts or screwdrivers ♦ Do not repair load chain installation in the block using tools such as pins...

Open the catalog to page 5

Lever Hoist ♦ Heat treated steel plates, gears , shafts for additional strength ♦ Forged upper, lower hooks with forged steel safety latches ♦ Free-wheeling mechanism for quick chain adjustments ♦ Weston style automatic load brake with double pawl load reduction ♦ 360° rotating handle of ease of use in confined space ♦ Rubber grip for non-slip handling ♦ Individual Serial number, Working Load Limit and MORDEC shown Proof Load: Safety Factor High Tensile Alloy Steel Chain and Hooks Powder Coated Individually Proof Tested to 1.5 Times of Working Load Limit Fatigue Tested at 1.5 times of...

Open the catalog to page 6

Chain Block Bearing Type ♦ Tough external case body with embossment ♦ Bearing type for smooth operations ♦ Compact and light weight for flexible application ♦ Double pawl brake mechanism for secure operations ♦ Heat treated steel plates, gears and shafts for enhanced strength ♦ Forged upper, lower hooks with forged steel safety latches ♦ Individual Serial number, Working Load Limit and MORDEC shown Material: High Tensile Alloy Steel Chain and Hooks Construction: Quenched and Tempered Finish: Powder Coated Proof Load: Individually Proof Tested to 1.5 times of Working Load Limit Fatigue:...

Open the catalog to page 7

Chain Block Bushing Type ♦ Compact and light weight for flexible application ♦ Load sheave with sealed roller bearings and reinforced gear casing ♦ Heat treated steel plates, gears and shafts for enhanced strength ♦ Forged upper, lower hooks with forged steel safety latches ♦ Individual Serial number, Working Load Limit and MORDEC shown Material: High Tensile Alloy Steel Chain and Hooks Construction: Quenched and Tempered Finish: Powder Coated Proof Load: Individually Proof Tested to 1.5 times of Working Load Limit Fatigue: Fatigue Tested at 1.5 times of Working Load Limit to 2000 cycles...

Open the catalog to page 8

Plain Trolley ♦ Designed to function on both flat and minor irregular beams surfaces ♦ Easy installation and on-site operations ♦ Dual tread Iron wheels with high quality sealed ball bearing ♦ Heavy rolled steel side plates with a universal hanging eye ♦ Powder coated body and wheels for protection from corrosion ♦ Individual Serial number, Working Load Limit and MORDEC shown

Open the catalog to page 9

Grade 80 Alloy Load Chain ♦ Designed for use with Mordec Lever Hoist and Chain Blocks ♦ High tensile steel for tougher and more reliable usage ♦ Economical to replace load chain rather than entire unit ♦ Strong and uniform chain link welding Material: High Tensile Forged Alloy Steel Construction: Quenched and Tempered Finish: Blackened Proof Load: Proof Load Tested at 2.5 times of Working Load Limit

Open the catalog to page 10All MEP Systems catalogs and brochures

-

MAK-TW

1 Pages

-

MAK-SP

1 Pages

-

MAK-DF

1 Pages

-

MAK-AC

1 Pages

-

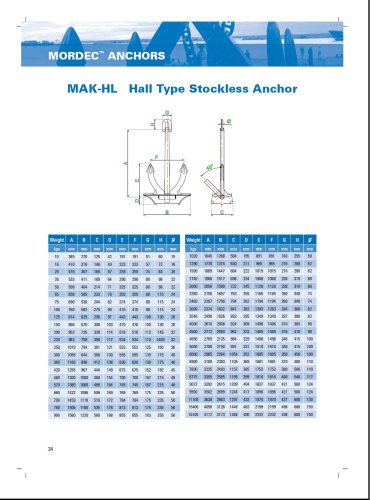

MAK-HL

1 Pages

-

Cargo securing equipment

7 Pages

-

MORDEC? Wire Ropes

30 Pages

-

MORDEC? Anchors

14 Pages

-

MORDEC? Anchor Chain & Fittings

22 Pages

-

SHACKLES

7 Pages

-

MORDEC? Hull Fittings

26 Pages

-

MORDEC? Synthetic Ropes

10 Pages

-

Hose Reel

1 Pages

-

Spooler

1 Pages

-

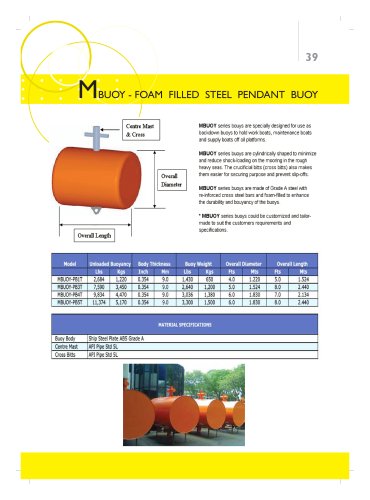

M-Buoy

1 Pages