Catalog excerpts

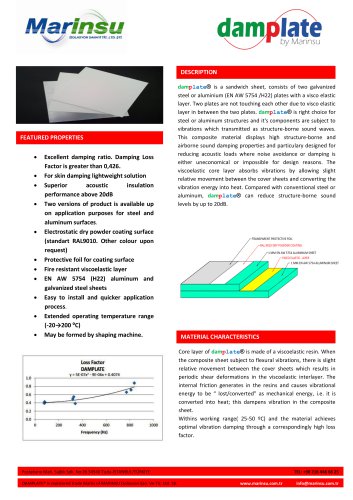

FEATURED PROPERTIES • Excellent damping ratio. Damping Loss Factor is greater than 0,426. • For skin damping lightweight solution • Superior acoustic insulation performance a bove 20 dB • Two versions of product is available up on application purposes for steel and alumin um surfaces. • Electrostatic dry powder coating surface (standart RAL9010. Other colour upon request) • Protective foil for coating surface • Fire resistant viscoelastic layer galvanized steel sheets • Easy to install and quicker application process. • Extended operating temperature range (-20->200 °C) • May be formed by shaping machine. damplate® is a sandwich sheet, consists of two galvanized steel or alumi nium (EN AW 5754 /H22) plates with a visco elastic layer . Two plates are not touching each other due to visco elastic layer in between the two plates. damplate® is right choice for steel or aluminum structures and it's components are subject to vibrations which transmitted as structure-borne sound waves. This composite material displays high structure-borne and airborne sound dampi ng properties and particulary designed for reducing acoustic loa ds where noise avoidance or damping is either uneco nomical or impossible for design reasons. The visco elastic core layer absor bs vibra tions by allowing slight relative move ment between the cover sheets and converting the vibra tion ene rgy into heat. Compared with conventional steel or alum inum, damplate® can reduce structure-borne sound levels by up to 20dB. MATERIAL CHARACTERISTICS Core layer of damplate® is made of a viscoelastic resin. When the composite sheet subject to flexural vibrations, there is slight relative movement between the cover sheets which results in periodic shear deformations in the viscoelastic interlayer. The internal friction generates in the resins and causes vibrational energy to be " lost/converted" as mechanical energy, i.e. it is converted into heat; this dampens vibration in the composite shee t. Withins working range( 25-50 °C) and the material achieves optimal vibration damping through a correspondingly high loss factor. Postahane Mah. Saglik Sok. No:26 34940 Tuzla-iSTANBUL/TURKiYE DAMPLATE® is registered trade Marks of MARINSU izolasyon San. Ve Tic. Ltd. $ti.

Open the catalog to page 1

PROCESSING APLICATIONS Joining damplate® may be united by all common j oining techniques. Mechanical methods including joining with screws or riverts, but also folding and clinching. Adhesive bonding, resistance and fusion welding are other commonly used methods. Most mechanical joining techniques commonly used with normal metal sheet and this can be applied to the composite material without tooling modifications.The strenghts of resulting joints are in the same order of magnitude as those obtained with steel sheet. Screws requires to tighten to a specific torque and it should be noted that...

Open the catalog to page 2All Marinsu İzolasyon Sanayi ve Ticaret Ltd. Şti. catalogs and brochures

-

Dampaste Cut Sheet

2 Pages

-

02-DTM Spec Sheet 0704-3

2 Pages

-

MSC-dB Spec Sheet

2 Pages