Catalog excerpts

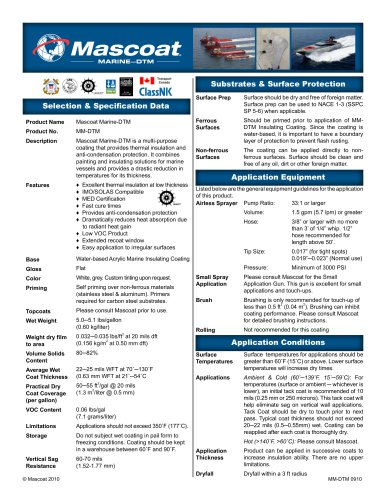

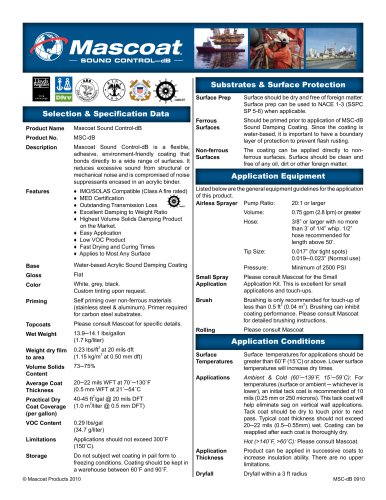

Selection & Specification Data Product Name Product No. Description Features Base Gloss Mascoat Marine-DTM MM-DTM Mascoat Marine-DTM is a multi-purpose coating that provides thermal insulation and anti-condensation protection. It combines painting and insulating solutions for marine vessels and provides a drastic reduction in temperatures for its thickness. ♦ Excellent thermal insulation at low thickness ♦ IMO/SOLAS Compatible ♦ MED Certification ♦ Fast cure times ♦ Provides anti-condensation protection ♦ Dramatically reduces heat absorption due to radiant heat gain ♦ Low VOC Product ♦ Extended recoat window ♦ Easy application to irregular surfaces Water-based Acrylic Marine Insulating Coating Flat Substrates & Surface Protection Surface Prep Surface should be dry and free of foreign matter. Surface prep can be used to NACE 1-3 (SSPC SP 5-6) when applicable. Ferrous Should be primed prior to application of MM- Surfaces DTM Insulating Coating. Since the coating is water-based, it is important to have a boundary layer of protection to prevent flash rusting. Non-ferrous The coating can be applied directly to nonSurfaces ferrous surfaces. Surface should be clean and free of any oil, dirt or other foreign matter. Application Equipment Listed below are the general equipment guidelines for the application of this product. Airless Sprayer Pump Ratio: 33:1 or larger Hose: 3/8” or larger with no more than 3' of 1/4” whip. 1/2” hose recommended for length above 50'. Tip Size: 0.017” (for tight spots) Color Priming Topcoats Wet Weight Weight dry film to area Volume Solids Content Average Wet Coat Thickness Practical Dry Coat Coverage (per gallon) VOC Content Limitations Storage White, grey. Custom tinting upon request. Self priming over non-ferrous materials (stainless steel & aluminum). Primers required for carbon steel substrates. Please consult Mascoat prior to use. 5.0—5.1 lbs/gallon (0.60 kg/liter) 0.032—0.035 lbs/ft2 at 20 mils dft (0.156 kg/m2 at 0.50 mm dft) 80—82% 22—25 mils WFT at 70°—130°F (0.63 mm WFT at 21°—54°C 50—55 ft2/gal @ 20 mils (1.3 m2/liter @ 0.5 mm) Small Spray Application Brush Rolling Please consult Mascoat for the Small Application Gun. This gun is excellent for small applications and touch-ups. Brushing is only recommended for touch-up of less than 0.5 ft2 (0.04 m2). Brushing can inhibit coating performance. Please consult Mascoat for detailed brushing instructions. Not recommended for this coating Application Conditions Surface Surface temperatures for applications should be Temperatures greater than 60°F (15°C) or above. Lower surface temperatures will increase dry times. Vertical Sag Resistance 0.06 lbs/gal (7.1 grams/liter) Applications should not exceed 350°F (177°C). Do not subject wet coating in pail form to freezing conditions. Coating should be kept in a warehouse between 60°F and 90°F. 60-70 mils (1.52-1.77 mm) Applications Ambient & Cold (60°—139°F, 15°—59°C): For temperatures (surface or ambient — whichever is lower), an initial tack coat is recommended of 10 mils (0.25 mm or 250 microns). This tack coat will help eliminate sag on vertical wall applications. Tack Coat should be dry to touch prior to next pass. Typical coat thickness should not exceed 20—22 mils (0.5—0.55mm) wet. Coating can be reapplied after each coat is thoroughly dry. Hot (>140°F, >60°C): Please consult Mascoat. Application Product can be applied in successive coats to Thickness increase insulation ability. There are no upper Dryfall Dryfall within a 3 ft radius

Open the catalog to page 1

Cleanup & Safety Other Coating Specifications Item Mixing Only a mud mixing paddle should be used. Use 1/2” drill motor to stir contents with paddle. Make sure drill is set to reverse to ensure that the paddle will not mar the bucket’s inner wall. Please consult Mascoat for paddle, if needed. Thinning Thinning is normally not needed. Please consult Mascoat for specific instructions if thinning is desired. Pot life Coating is one part, so no catalyzation is needed. Pail can be reused if properly sealed. Container 5 gallon pail (18.92 liters) Container Wet 27.5—28.0 lbs per 5 gallon pail...

Open the catalog to page 2All Marinsu İzolasyon Sanayi ve Ticaret Ltd. Şti. catalogs and brochures

-

Dampaste Cut Sheet

2 Pages

-

MSC-dB Spec Sheet

2 Pages

-

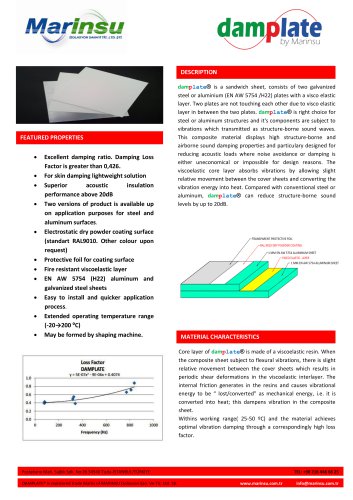

damplate

2 Pages