Catalog excerpts

The MarFlex Deepwell Pump

Open the catalog to page 1

Deck arrangement Pipe stack

Open the catalog to page 2

The MarFlex Deepwell Pump Deepwell pumps with a so-called ‘cargo-lubricated’ driveshaft for chemical and product tankers had already been produced for many years by various well-known pump manufacturers. The operational disadvantages of this design, however, are very familiar in the shipping industry. As the new MarFlex deepwell pump needed to be driven by an electric motor, we first had to develop a ‘non-cargo-lubricated’ driveshaft. This resulted in a unique ‘oil-lubricated’ shaft running in a separate supporting pipe. The service life of an oil-lubricated shaft arrangement is more than...

Open the catalog to page 3

Deck arrangement The MarFlex deepwell pump can be driven by an explosion-proof, class-approved electric motor or a hydraulic motor. However, 99% of all the deepwell pumps installed by MarFlex since the introduction of the new design in 1987 are electrically driven, for the following reasons: Advantages of electric-drive deepwell pumps compared with hydraulic-drive deepwell or submerged pumps: • Total system efficiency approximately 20% higher; • Low noise level; • Easy to install, thanks to the electrical wiring instead of a complicated hydraulic piping system (commissioning is reduced to a...

Open the catalog to page 5

Pipe stack The design of the MarFlex deepwell pump is based on a driveshaft that is separated from the cargo. The pipe stack consists of two pipes: one is the discharge pipe and the other is the enclosure for the intermediate driveshaft, the shaft bearings and the lubricating oil. The separation of the shaft from the cargo gives the following obvious advantages: • The drive shaft is made of 42CrMo4V, which is a heat treatable steel. If the shaft were exposed to the cargo, it would be necessary to use AISI 316L steel, which is not the ideal material for a deepwell pump driveshaft. • Because...

Open the catalog to page 6

Pumphead The MarFlex deepwell pump is designed in such a way that the total pump head can be disconnected from the pipe stack, which makes maintenance very easy. A so-called 'spline' connection between the intermediate driveshaft and the pump shaft in the pump head makes it possible to disconnect the pump head from the pipe stack by lowering the pump head. 1. The pump shaft This shaft is made of 32CrNiMo6V steel, a very high grade steel that is ideal for this purpose. Like the intermediate driveshaft, the pump shaft is not made of AISI 316L because it is oil-lubricated rather than being...

Open the catalog to page 8

Pump materials The MarFlex deepwell pump is made entirely of stainless steel AISI 316L. On request, the MarFlex deepwell pump can also be made from higher grade materials, such as ‘duplex’ or ‘super duplex’, to fulfill the customer’s requirements. All seals and O-rings in contact with the cargo are made of PTFE or FFPM. Thanks to the materials used, the MarFlex deepwell pump is highly chemical-resistant and suitable for handling cargoes with a temperature up to 10

Open the catalog to page 9

Stripping procedure When the cargo tank is empty, the cargo stripping valve must be opened and the main cargo valve closed. The residual cargo left in the main cargo pipe is removed by forcing inert gas or air via the stripping pipe into the cargo line on deck. During the stripping procedure, the pump should be kept running (the impeller acts as a dynamic foot valve) until the cargo pipe is completely empty. This procedure guarantees an absolute minimum of residual cargo in the pump well, and complies with all IMO rules. Inert gas / air under pressure Outlet stripping pipe Main cargo pipe...

Open the catalog to page 10

NON-RETURN VALVE STRIPPING CARGO PIPE CARGO STRIPPING VALVE FLEXIBLE HOSE OPEN SNAP-ON-COUPLING MAIN CARGO VALVE CLOSED MAIN CARGO PIPE OPTIONAL: DIRECTLY TO MANIFOLD SNAP-ON-COUPLING OPEN INERT GAS / AIR UNDER PRESSURE

Open the catalog to page 11

MarFlex Europe (Headquarters) Oud-Beijerland The Netherlands info@marflex.com MarFlex Services Oud-Beijerland The Netherlands service@marflex.com MarFlex Asia Hong Kong MarFlex Guangzhou Guangzhou China MarFlex Moscow Moscow Russia Louis Pasteurstraat 8 3261 LZ Oud-Beijerland The Netherlands T +31-186-890200 F +31-186-890249 info@marflex.com www.marflex.com vr/ MarFlex Pumping Excellence

Open the catalog to page 12All Marflex catalogs and brochures

-

Cargo cooling

1 Pages

-

Remote Access

1 Pages

-

NQZR

1 Pages

-

VSDS

1 Pages

-

Hose reel

1 Pages

-

Cargo hoses

1 Pages

-

Tripod

1 Pages

-

MSP-EH 16-200

1 Pages

-

MSP-500

1 Pages

-

MSP-200

1 Pages

-

MSP-150

1 Pages

-

MSP-100

1 Pages

-

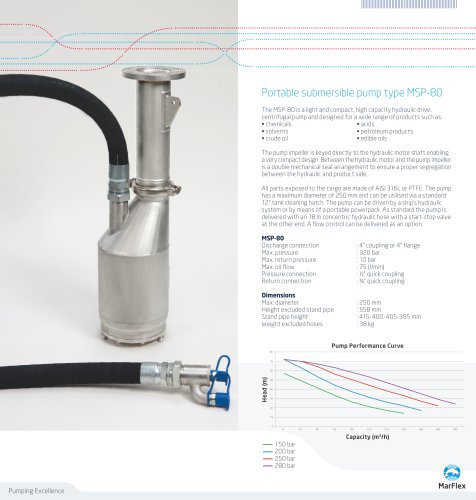

MSP-80

1 Pages

-

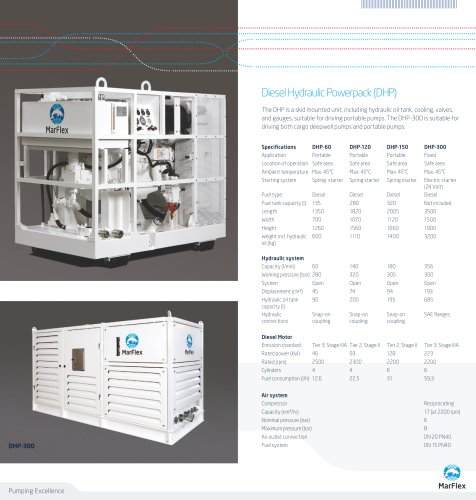

DHP 60/120/150

1 Pages

-

EHP 45/75/112

1 Pages

-

Draining pump

1 Pages

-

MBDPC 150/200/300/400/500

1 Pages

-

MDPC 250/300

1 Pages

-

MDPD 80/100/150/200

1 Pages

-

Pump Control Desk

1 Pages

-

Demineralising water unit

1 Pages