Catalog excerpts

New generation diesel engines LDW 194 JMTI LDW 245 JMTI/A

Open the catalog to page 1

Lombardini Marine, a division of the Lom- bardini Group, was set up with the objective of preparing and marketing engines based on the innovative JMT design and on well established and proven FOCS and CHD fami- Having a very modern and well-equipped plant, it can count on a team with repuded experience in the marine sector and with some twenty years of expertise to enable the latest features and technological advan- ces available to be designed into the pro- Lombardini Marine engines, which are extremely lightweight and compact, can now offer the highest reliability, thus allowing owners to...

Open the catalog to page 3

The JMT series engines represent the highest point of development of the technology applied to diesel engines for the marine sector for both pleasure and commercial applications. We have worked intensively, taking advantage of the experience acquired over many years of work and experimentation on traditional engines, which were already at the leading edge, with the introduction of compact injector pumps, in order to be able to use the Common Rail injection system. The new Common Rail generation New EDC16 electronic control unit with high-tech injectors delivering 5 injections per phase. A...

Open the catalog to page 4

The Common Rail - Multiple Injection combination has drastically reduced consumption, which in the marine sector is synonymous with greater range and being able to travel further without intermediate fuel stops. For example, the LDW 194 JMTI engine has specific consumption of 162 gCV/h at 2750 RPM, which is one The Common Rail-Multiple Injection features enable this engine to improve the main aspect of diesel in environmental terms, by minimising the main defect represented by the emission of particulate and NOx. The JMT engine meets exhaust emission require- ments and already conforms to...

Open the catalog to page 5

Technical features Common Rail Injection System The Common Rail injection system makes it possible to use a high injection pressure and a fuel delivery method which are controlled by an electronic control unit through electro-injectors (rather than by injec- tion pumps as in traditional direct injection engines). The high injection pressure is the fundamental tool for optimising torque delivery, fuel consumption and amount of exhaust smoke. The injection pressure is adjustable thanks to the constructional features of the system that is equipped with pressure pump and independent elec-...

Open the catalog to page 6

Technical features Block - head - cylinders The cylinders are formed directly in the block, which is in ductile cast iron, and are available in three dimensional classes plus oversize. The cylinder head is a monoblock in aluminium and silicon alloy. There are four valves for each cylinder, two for the inlet and two for the exhaust. Parallel and vertical, they are mounted in their respective valveguides and controlled by two camshafts whose eccentric cams actuate the hydraulic valve tappets. Fixed geometry turbine To ensure reliability and long-life in the demanding marine environment, and...

Open the catalog to page 7

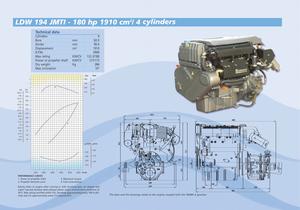

Technical data_ Power at propeller shaft KW/CV PERFORMANCE CURVES 1. Power at propeller shaft 2. Propeller demand curve g/KWti g/CVh Rating refers to engine after running In with reversing gear, air cleaner and water Injected stainless steel exhaust elbow under environment conditions of 20°C. Max rating certified within 5%. Derating approximately every 100 m alti- tude and 2% approximately every 5°C beyond 20°C. The data and the drawings relate to the engine coupled with the TM48S A gearbox

Open the catalog to page 8

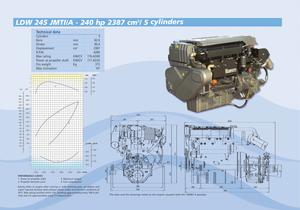

Technical data Power at propeller shaft KW/CV 171.4/233 PERFORMANCE CURVES 1. Power at propeller shaft 2. Propeller demand curve Rating refers to engine after running In with reversing gear, air cleaner and water Injected stainless steel exhaust elbow under environment conditions of 20°C. Max rating certified within 5%. Derating approximately every 100 m alti- tude and 2% approximately every 5°C beyond 20°C. The data and the drawings relate to the engine coupled with the TM485 A gearbox

Open the catalog to page 9

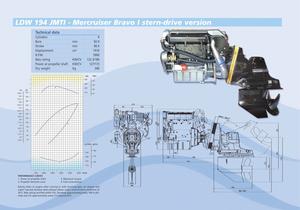

LDW 194 JMTI - Mercruiser Bravo I stern-drive version Technical data Power at propeller shaft KW/CV PERFORMANCE CURVES 1. Power at propeller shaft 2. Propeller demand curve Rating refers to engine after running In with reversing gear, air cleaner and water Injected stainless steel exhaust elbow under environment conditions of 20°C. Max rating certified within 5%. Derating approximately every 100 m alti- tude and 2% approximately every 5°C beyond 20°C.

Open the catalog to page 10

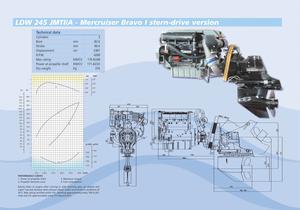

LDW 245 J M TI/A - Mercruiser Bravo I stern-drive version Technical data Power at propeller shaft PERFORMANCE CURVES 1. Power at propeller shaft 2. Propeller demand curve Rating refers to engine after running In with reversing gear, air cleaner and water Injected stainless steel exhaust elbow under environment conditions of 20°C. Max rating certified within 5%. Derating approximately every 100 m alti- tude and 2% approximately every 5°C beyond 20°C.

Open the catalog to page 11

LDW 194 JMTIILDW 245 JMTI/A - Gearboxes - Accessories * Gearbox output flange 8° inclined - Stern drive arrangement

Open the catalog to page 12

Engine equipment Electric starting with 12V motor, alternator 120 A, sea water pump, electric fuel supply pump, mounted oil extraction pump, hydraulic inverter-reduction unit, sockets for inverter and accelerator controls, De Luxe Maxi instrumentation panel, 5 metre extension, set of spanners and tools, anti-vibration mounts, use and maintenance manual. De Luxe Maxi instrument panel Engine rubber mounts

Open the catalog to page 13

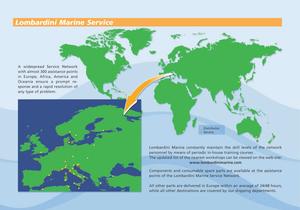

Lombardini Marine Service A widespread Service Network with almost 300 assistance points in Europe, Africa, America and Oceania ensure a prompt re- sponse and a rapid resolution of Lombardini Marine constantly maintain the skill levels of the personnel by means of periodic in-house training courses . The updated list of the nearest workshops can be viewed on the web-site: Components and consumable spare parts are available at the assistance points of the Lombardini Marine Service Network. All other parts are delivered in Europe within an average of 24/48 hours, while all other destinations...

Open the catalog to page 14All Lombardini Marine catalogs and brochures

-

KDI TCR-MP

7 Pages

-

GENSET ENGINES – MG SERIES

1 Pages

-

Lmg catalogue

8 Pages

-

catalogo_lombardini_eng

20 Pages

Archived catalogs

-

catalogo_lombardini_eng

20 Pages