Catalog excerpts

The Electrolux Dishwashing range is produced for customers with the highest conceivable demands for good efficiency, economy and ergonomics for dishwashing operation. The rack type dishwasher WTM300 has a capacity up to 300 racks per hour with 2 speeds. The range consists of 2 electrically heated models (feed from left or right) available with or without Energy Saving Device (ESD). EASY TO INSTALL • Solid 3mm square stainless steel sub-frame with bolt-together construction that can be delivered assembled or in modules to be connected on site. • Stainless steel wash pumps. • Brass inlet valves as standard. • All rear positioned water tubes in stainless steel. • Only one cable for electrical connection. • Electrical and water connections centralized in one area. • Service from the front and from the side. • Prearrangements for automatic detergent dispenser, energy management device and HACCP implementation. FUNCTIONAL ZONES • Separate 150 litre pre-wash zone with 2.2 kW pump supplying upper wash arms and 1.1 kW pump supplying lower wash arms, without detergent for maximum dirt removal incorporates automatic partial drain. • Power wash zone where all the soil is removed with Maximum Water contact wash arms. • Rinse area equipped with the DUO-rinse system. • Atmospheric boiler combined with the rinse booster pump for perfect rinsing performances in terms of sanitation, energy saving, independence from the water pressure on the network. • Incorporates non-return (air gap class A) valve. • Can be equipped with a drying zone for fast and efficient drying (optional extra). EASY TO CLEAN AND MAINTAIN • The rinse & wash tank is pressed with completely rounded corners and sloping base. • Smooth surfaces. Main internal components made in 304 AISI stainless steel as well as the external panels. • Easy removable ash arms and double tank filter (flat and deep box). • Height adjustable stainless steel feet. • Self-draining wash pumps provide maximum hygiene. • Hinged flap for easy access to the energy saving condenser unit. • Large balanced inspection doors for easy access to wash area. • Self-cleaning cycle in pre-wash,wash & rinse zones. EASY TO USE • Automatic start/stop function. • Simple electric control panel. • Counter balanced door with safety switch and easy to grip handle. • Built-in rinse water heater to increase the temperature of the final rinse water. • Electronic control panel with autodiagnostic check control. EASY ON THE ENVIRONMENT • 35mm thickness foam injection insulated doors • 98% recyclable by weight. • CFC free packaging. • Low noise level <70dBA. For further specifications and optional extras, please see overleaf.

Open the catalog to page 1

DISHWASHER WTM300 – FEED FROM LEFT Dimensions mm 1. Main switch 2. Mains supply connection 3. Hot water connection, temperature ca 50°C , ISO 228/1 DN 20 (G 3/4"), pressure 150– 700 kPa (1.5-7 bar) at 0.3 l/sec. 4. Cold water connection, temperature ca15°C , ISO 228/1 DN 20 (G 3/4"), pressure 150– 700 kPa (1.5-7 bar) at 0.3 l/sec. 5. Drain outlet 1 1/2" M, flow rate 120 l/min. Must be connected with 50 mm air gap to floor gully, designed for flow of 3 l/sec. 6. Condensation outlet 7. Detergent connection 8. Detergent probe 9. Equipotentional screw DISHWASHER WTM300 – FEED FROM RIGHT NOTE!...

Open the catalog to page 2

DISHWASHER WTM300 WTM200 – FEED FROM LEFT C Pre-wash module (1500mm) Dishwasher, washing module Dishwasher, rinse module Condenser unit/ESD - if ordered Drying zone – optional Specification – electrically heated models Capacity/h 1st speed/2ndspeed Capacity/litres wash tank Water flow litres/h Model dishes Loading kW (excl.optionals) Voltage * Wash pump/ duo rinse pump/pre-wash * Other voltages available on request OPTIONAL EXTRAS: Model Drying zone ADT 900– feed from left, see below Drying zone ADT 900– feed from righ, see below Drain kit for Modular + Compact rack type 1. Drain outlet 1...

Open the catalog to page 3

7-254 Subject to changes without notice. Subject to changes without notice.

Open the catalog to page 4All Loipart AB catalogs and brochures

-

1693151501

3 Pages

-

9S0990

3 Pages

-

9S0870

3 Pages

-

9S1007

3 Pages

-

9S1008

3 Pages

-

9S0895

3 Pages

-

L12065

3 Pages

-

L13013

3 Pages

-

L13012

3 Pages

-

371151

4 Pages

-

371150

4 Pages

-

371015M60

3 Pages

-

DZH1CE

3 Pages

-

PC 6 ETX

3 Pages

-

B10

3 Pages

-

504265

4 Pages

-

504264

4 Pages

-

505080

3 Pages

-

505079

3 Pages

-

169316

3 Pages

-

LB150

4 Pages

-

R04PVG

4 Pages

-

C600S/L

3 Pages

-

9S0891

3 Pages

-

9S0890

3 Pages

-

371149

3 Pages

-

E7ECEH4R

3 Pages

-

391184

3 Pages

-

MCLLEAJ8DM

3 Pages

-

E7ECEH4Q

3 Pages

-

DZL2CE

3 Pages

-

E7ECMH4RE

3 Pages

-

CP-2

3 Pages

-

EVO-250M

3 Pages

-

BR-6 ETX

3 Pages

-

Spiral Dough Mixer L15019

3 Pages

-

Spiral Dough Mixer 9S0747

3 Pages

-

Spiral Dough Mixer 9S0750

3 Pages

-

Spiral Dough Mixer 9S0749

3 Pages

-

ESPRESSO MACHINE, 2 GROUPS

3 Pages

-

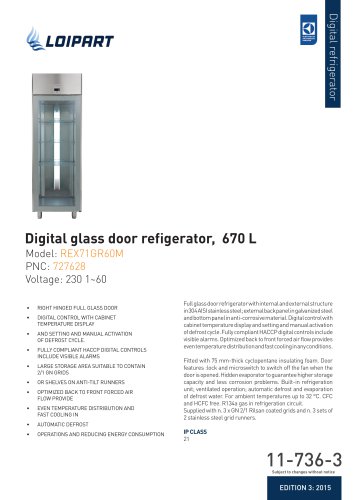

Glass Door Refrigerator 670L

2 Pages

-

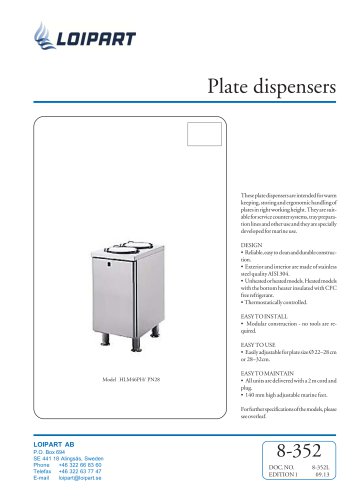

Plate Dispenser Unit FX04N

2 Pages

-

Plate Dispenser, unheated

2 Pages

-

Soap Dispenser S/S

2 Pages

-

Wallmounted mixer tap

2 Pages

-

Mixer Tap Single Lever

2 Pages

-

Mixer tap, touch free

2 Pages

-

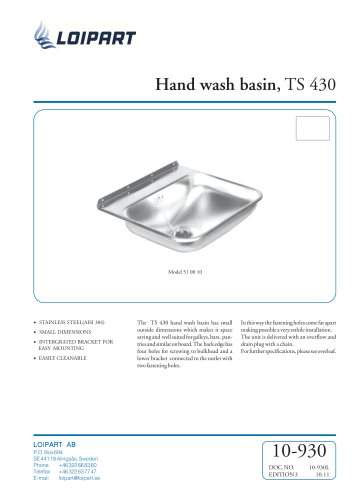

S/S Hand Wash Basin

2 Pages

-

S/S Wall Cupboard

2 Pages

-

S/S Flat Work Table

2 Pages

-

S/S Single Sink Unit T-29

2 Pages

-

S/S Single Sink Unit BE-50

2 Pages

-

S/S Double Sink Unit BD-50

2 Pages

-

Deep Fat Fryer

1 Pages

-

Dough sheeters, Econom

4 Pages

-

Spiral dough mixer PSF50

2 Pages

-

Bakers Table, 1600mm

2 Pages

-

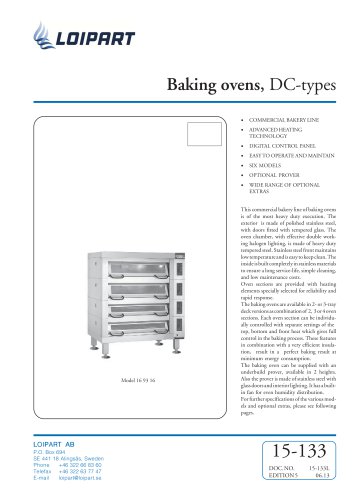

Baking ovens, DC-types

4 Pages

-

Maximat S40/80/S120/S160

2 Pages

-

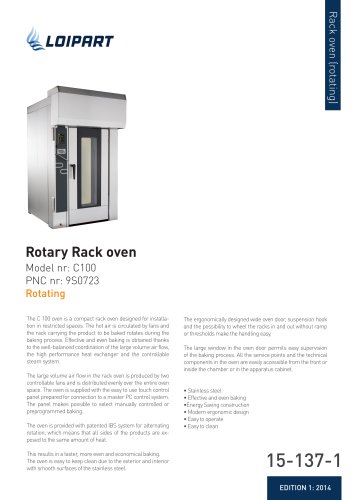

Rotary Rack oven C100

2 Pages

-

Marine Freezer 400L

4 Pages

-

Dishwasher WTM200EA

4 Pages

-

Dishwasher WTM165EA

4 Pages

-

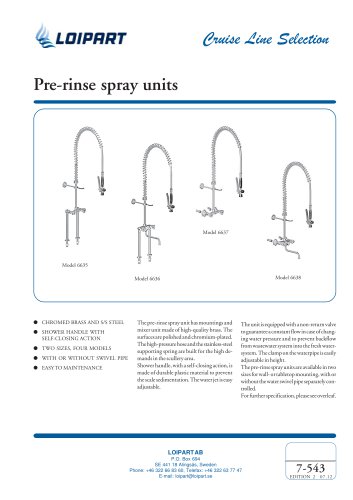

Pre-Rinse Spray Unit

2 Pages

-

Marine Toaster (TK-72)

2 Pages

-

Marine Tiltable Frying Table

2 Pages

-

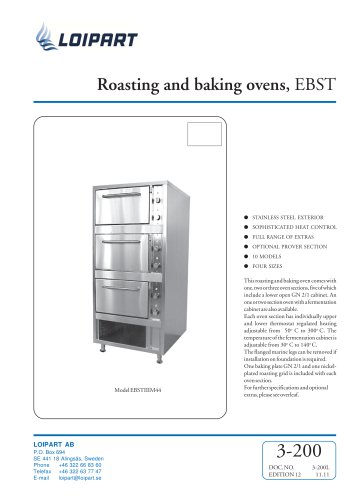

Leaflet 3-200

2 Pages

-

Leaflet 15-133

4 Pages

-

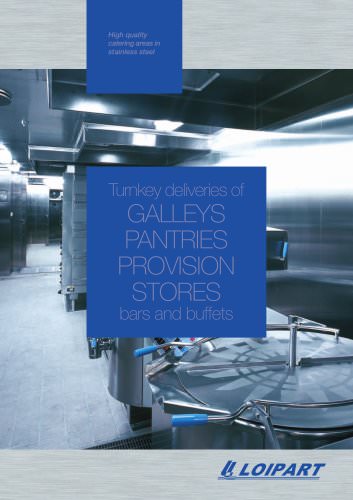

Brochure - Merchant

2 Pages

-

Brochure - Offshore

2 Pages

-

Brochure - Passenger

2 Pages

-

Pasta cooker, electric

2 Pages

-

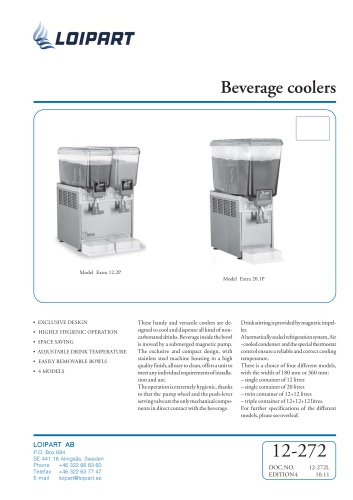

Beverage coolers

2 Pages

-

Bar equipment

2 Pages

-

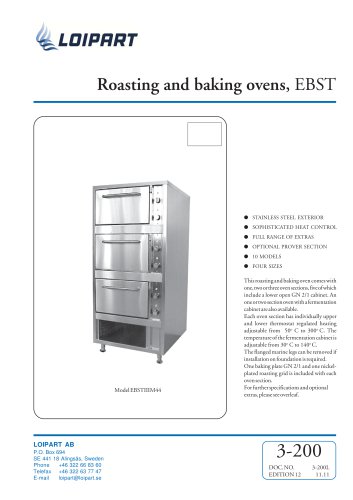

Roasting and baking ovens,

2 Pages

-

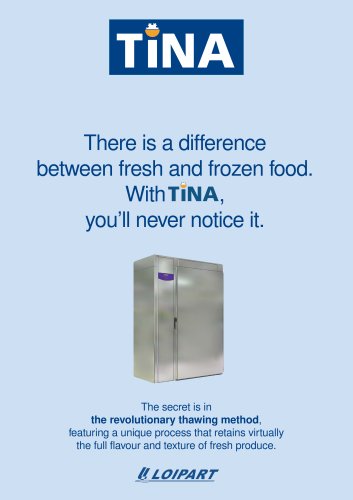

Loipart TINA 2006

4 Pages