Catalog excerpts

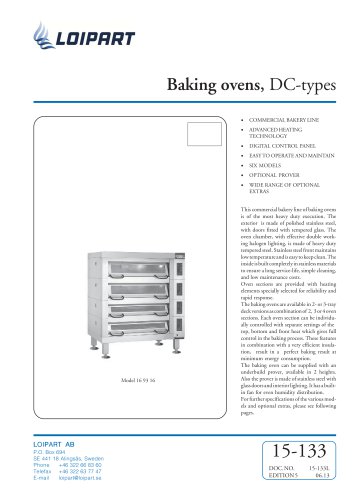

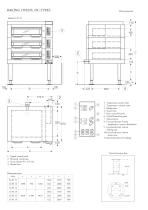

Baking ovens, DC-types • COMMERCIAL BAKERY LINE • ADVANCED HEATING TECHNOLOGY • DIGITAL CONTROL PANEL • EASY TO OPERATE AND MAINTAIN • SIX MODELS • OPTIONAL PROVER • WIDE RANGE OF OPTIONAL EXTRAS This commercial bakery line of baking ovens is of the most heavy duty execution. The exterior is made of polished stainless steel, with doors fitted with tempered glass. The oven chamber, with effective double working halogen lighting, is made of heavy duty tempered steel. Stainless steel front maintains low temperature and is easy to keep clean. The inside is built completely in stainless materials to ensure a long service-life, simple cleaning, and low maintenance costs. Oven sections are provided with heating elements specially selected for reliability and rapid response. The baking ovens are available in 2- or 3-tray deck versions as combination of 2, 3 or 4 oven sections. Each oven section can be individually controlled with separate settings of the top, bottom and front heat which gives full control in the baking process. These features in combination with a very efficient insulation, result in a perfect baking result at minimum energy consumption. The baking oven can be supplied with an underbuild prover, available in 2 heights. Also the prover is made of stainless steel with glass doors and interior lighting. It has a built-in fan for even humidity distribution. For further specifications of the various models and optional extras, please see following

Open the catalog to page 1

2. Temperature -desired value 5. Heat control buttons 6. On/off button for panel 8. Increase/decrease button -temperature / power distribution 9. Increase/decrease button -baking time 10.Increase/decrease button -steam time 11.Start/stop button for baking Detail of marine foot 1. Digital control panel

Open the catalog to page 2

Installation The electrical connection and control panel are located on the right side of the machine. In order not to overheat components leave some free space on the right side. For access during servicing and installation appr. 500 mm is needed. If the oven is fitted with an optional extra steam generator (add 1.8 kW) an additional 200 mm wide space is needed between back of machine and bulkhead or other neighbouring equipment. Water and drain applies only for models with built-in steam where a special instruction exists. 150 - 200 m3/h 50 - 80°C air is emitted from the oven. The...

Open the catalog to page 3

BAKING OVENS, DC-TYPES 15-133 Subject to changes without notice.

Open the catalog to page 4All Loipart AB catalogs and brochures

-

1693151501

3 Pages

-

9S0990

3 Pages

-

9S0870

3 Pages

-

9S1007

3 Pages

-

9S1008

3 Pages

-

9S0895

3 Pages

-

L12065

3 Pages

-

L13013

3 Pages

-

L13012

3 Pages

-

371151

4 Pages

-

371150

4 Pages

-

371015M60

3 Pages

-

DZH1CE

3 Pages

-

PC 6 ETX

3 Pages

-

B10

3 Pages

-

504265

4 Pages

-

504264

4 Pages

-

505080

3 Pages

-

505079

3 Pages

-

169316

3 Pages

-

LB150

4 Pages

-

R04PVG

4 Pages

-

C600S/L

3 Pages

-

9S0891

3 Pages

-

9S0890

3 Pages

-

371149

3 Pages

-

E7ECEH4R

3 Pages

-

391184

3 Pages

-

MCLLEAJ8DM

3 Pages

-

E7ECEH4Q

3 Pages

-

DZL2CE

3 Pages

-

E7ECMH4RE

3 Pages

-

CP-2

3 Pages

-

EVO-250M

3 Pages

-

BR-6 ETX

3 Pages

-

Spiral Dough Mixer L15019

3 Pages

-

Spiral Dough Mixer 9S0747

3 Pages

-

Spiral Dough Mixer 9S0750

3 Pages

-

Spiral Dough Mixer 9S0749

3 Pages

-

ESPRESSO MACHINE, 2 GROUPS

3 Pages

-

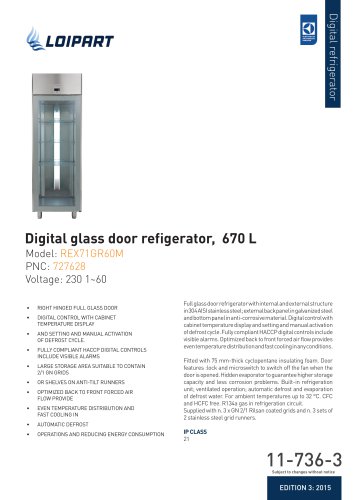

Glass Door Refrigerator 670L

2 Pages

-

Plate Dispenser Unit FX04N

2 Pages

-

Plate Dispenser, unheated

2 Pages

-

Soap Dispenser S/S

2 Pages

-

Wallmounted mixer tap

2 Pages

-

Mixer Tap Single Lever

2 Pages

-

Mixer tap, touch free

2 Pages

-

S/S Hand Wash Basin

2 Pages

-

S/S Wall Cupboard

2 Pages

-

S/S Flat Work Table

2 Pages

-

S/S Single Sink Unit T-29

2 Pages

-

S/S Single Sink Unit BE-50

2 Pages

-

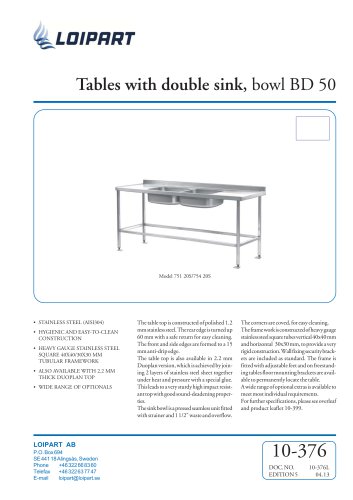

S/S Double Sink Unit BD-50

2 Pages

-

Deep Fat Fryer

1 Pages

-

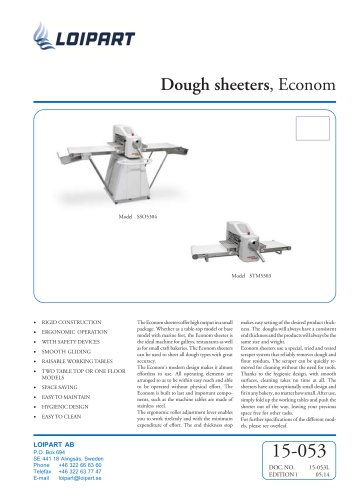

Dough sheeters, Econom

4 Pages

-

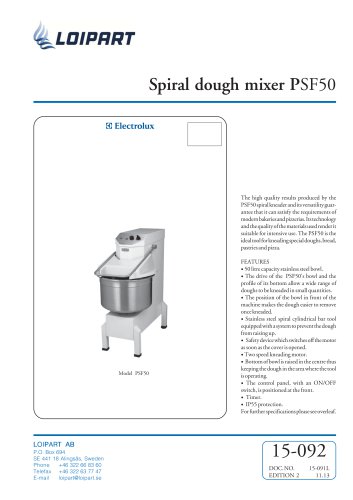

Spiral dough mixer PSF50

2 Pages

-

Bakers Table, 1600mm

2 Pages

-

Maximat S40/80/S120/S160

2 Pages

-

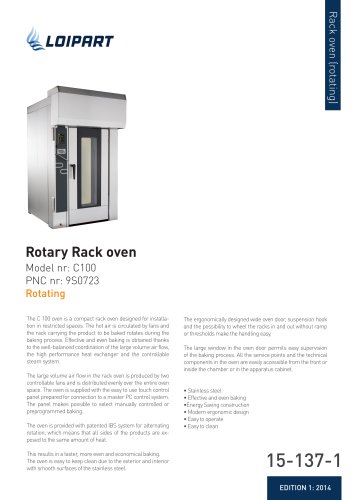

Rotary Rack oven C100

2 Pages

-

Marine Freezer 400L

4 Pages

-

Dishwasher WTM300EA

4 Pages

-

Dishwasher WTM200EA

4 Pages

-

Dishwasher WTM165EA

4 Pages

-

Pre-Rinse Spray Unit

2 Pages

-

Marine Toaster (TK-72)

2 Pages

-

Marine Tiltable Frying Table

2 Pages

-

Leaflet 3-200

2 Pages

-

Leaflet 15-133

4 Pages

-

Brochure - Merchant

2 Pages

-

Brochure - Offshore

2 Pages

-

Brochure - Passenger

2 Pages

-

Pasta cooker, electric

2 Pages

-

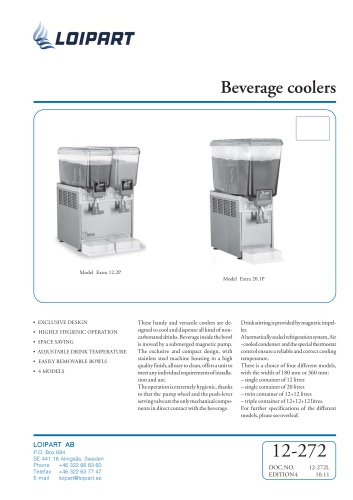

Beverage coolers

2 Pages

-

Bar equipment

2 Pages

-

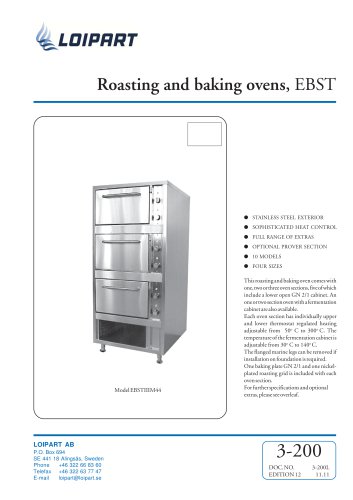

Roasting and baking ovens,

2 Pages

-

Loipart TINA 2006

4 Pages