Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

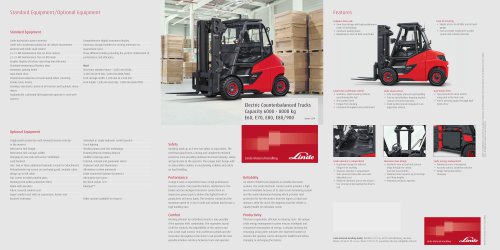

Standard and optional equipment Standard equipment Pneumatic tyres On-demand hydrostatic power steering for fuel economy and Fixed angle steering wheel easy and precise operation Comprehensive instrumentation High-performance hydraulic filter preserving maximum purity Internal rear-view mirror of oil for long life of all hydraulic components Standard clearview lift mast Full road lighting Non hydraulic fork carriage Cummins B3.3 Tier 3, water cooled diesel engine Forks – 1200 mm long (S30 – S60) 1400 mm 1400 mm long Engine intake air cleaner with integral safety element Linde Hydrostatic transmission Heavy-duty double hub reduction drive axle with internal disc Hydraulic deck tilt Standard colour scheme vermilion and charcoal grey Options Side opening cabin door Fork spreading carriage Audible warning reverse alarm Accumulator for hydraulic services Spark arrestor Maintenance 3 Thoughtful design, enabling easy access for routine maintenance procedures, results in maximum uptime ratios and therefore increased productivity and utilisation of the materials handling asset, for lower operating costs, and a faster return on investment Flashing or rotating beacons Exhaust purifier Deck widths 3 There is a choice of either 1220 mm or 1400 mm deck width to meet individual customer requirements. 3 The heavy section chequer plate deck has a tilt mechanism to facilitate easier, safer stacking, destacking and travelling 3 Hydraulic deck tilt External mirrors Heavy duty engine air filter Hydrostatic transmission 3 The Linde hydrostatic transmission sysyem has no clutch, multiple clutch pack, no reversing gear and none of the maintenance and costs associated with these parts. 3 The system is highly fuel efficient and excels in applications requiring smooth, precise handling and frequent travel direction changes Radio with compact disc player and speakers Duplex Full free lift mast Modern powerfull engine 3 Diesel engine stage III emissions 3 3-cylinder 3.3 ltr 3 63 kW rated at 2600 rpm Heavy-duty deck load guards Double stage mast 1050 mm free lift Load Controls 3 Standard operators controls provide effortless operation 3 At-hand individual hydraulic function controls 3 Line-of-sight instrumentation Carriage backrest extension Safety lighting Linde Free-sight Mast 3 Optimised mast profiles for long load handling 3 Cross cylinder traverse mechanism 3 Cushion switch on traverse for slow-down final retraction Alternative colour schemes Additional hydraulic circuits Tilting carriage Vertically moving forks Other options available on request Safety Perfect load control and manoeuvrability in close surroundings is assured at all times. Linde achieves this by locating the cabin in the optimised, forward position to allow optimised direct visibility to the mast and forks and onto the load decks. pressed, thus providing the operator with a comfortable working The visibility around the machine from the operating position environment. The standard operator’s seat is equipped with is optimised by the utilisation of generous glass panels to the hydraulic damping for additional cushioning. front, rear and sides. Reliability Performance The proven reputation of the hydrostatic drive system, together The finely tuned hydrostatic drive system delivers precision in with the powerful high-torque diesel engine provides a highly operation balanced with optimised speed of performance. The efficient and reliable drive system. The mast and integrated fork step-less drive system ensures that acceleration through to carriage have been thoroughly tested for endurance and secu- top speed through the final drive axle provides smooth opera- rity in operation to ensure a long operational life. tion. The precise operation of the hydrostatic system enables accurate load engagement, therefore limiting impact shocks. Productivity With the utilisation of the world-class hydrostatic drive system, speed and precision in operation is assured. The operational The operator’s cabin is mounted on the chassis using high- characteristics of the hydraulic drive system, and ergonomically density rubber mounts. This ensures that drive and power placed operator controls ensure that minimum operator move- train vibration, together with operational vibrations, are sup- 5540_TB_S30-S60_BR316.indd 1 Prozessfarbe CyanProzessfarbe MagentaProzessfarbe GelbProzessfarbe Schwarz CyanProzessfarbe MagentaProzessfarbe GelbProzessfarbe Subject to modification in the interests of engineering progress. Illustrations and technical details non-binding for actual construction. All measurements subject to customary tolerances. Steer axle with hydraulic drum brakes Hydraulic suspension comfort-class seat with wide range Power 3 A direct injection, water cooled diesel engine provides the power to match the output required for each model to ensure optimum performance. ment is required, thereby saving time and limiting fatigue. Linde Material Handling GmbH, Postfach 10 0136, 63701 Aschaffenburg, Germany Phone +49.6021.99-0, Fax +49.6021.99-1570, www.linde-mh.com, info@linde-mh.de Cabin with front and rear washer wipers with heater Operators Compartment 3 Forward positioned for optimised all-round visibility 3 Impact tested loadguard 3 Integrated overhead guard

Open the catalog to page 1

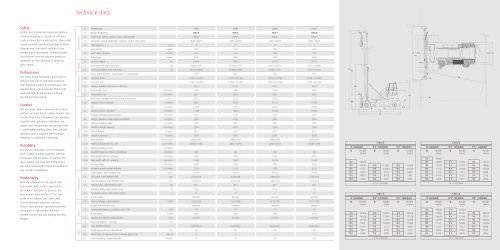

Technical data Lifting capacity diagrams Manufacturer Model designation Power unit: battery, diesel, LP gas, mains power Operation: manual, pedestrian, stand-on, seated, order picker Rider seated Rider seated Rider seated Rider seated Rider seated Rider seated Rider seated Rider seated Load capacity Load centre Platform edge to load face Axle load without load, front/rear Tyres, front/rear. SE = (superelastic), P = (pneumatic) Tyre size, front Tyre size, rear Wheels, number, front/rear (x = driven) Track width, front Track width, rear Mast/fork carriage/truck tilt, forward/backward Height...

Open the catalog to page 2All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

E60 – E80

2 Pages

-

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages