Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

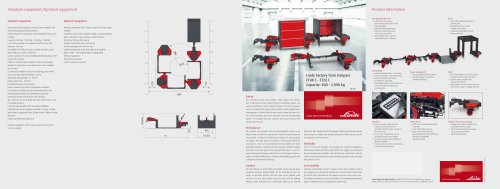

Standard equipment/Optional equipment Standardized front module and load carrier modules with Weather protection with roll-up curtain at the load carrier electrically powered lifting-spindles Different types of customized, interchangeable load carrier Customized load carrier modules adapt to existing trolleys Glide- and wear strips at trolley contact-surfaces Other load/trolley dimensions Load-carrier modules are equipped with PU-tires with Outdoor package with SE-twin-tires Possibility to lift different sizes of loads on trolleys from Lighting equipment at the last load carrier module (Rear-, brake- and flashing light, rotating light) Control console on truck and additional lift-operation at the Remote diagnostics load carrier module Alternative paintwork CAN bus communication between tractor and modules Further options on request Silent Silent lifting and lowering due to spindle drive Backlash-free load-carrier module connections suspension and tight fits avoid noise generation Weather protection with printed logo Directionally stable train Fully electrical steering, permanently monitored for best manoeuvrability Optimized driving-behaviour: fully electrical steering with active curve correction Train designed for a superbly controlled narrow cornering Optional equipment Standard equipment Product information Automatic tractor drive-lock when load-carrier modules are lowered Continuously monitored electrical steering system with Linde Factory Train Compact FT08 C - FT20 C Capacity: 800 - 2.000 kg BR 8961 active steering against drifting in curves Adjustable lifting height: 0 – 80 mm Lifting speed max. 10 mm/s Economical energy consumption Power connector to tractor and between modules Crab motion for obliquely side positioning of the train Operating hour meter and maintenance indicator Driving backwards possible for short distance Serviceability Easily maintained basic construction CAN bus controller with data memory Wheels and rollers are easily accessible for exchange Functional elements and bearings are service-friendly accessible and exchangeable Energy management Energy-optimized lifting system Reduced rolling resistance by optimized bearings Safety Drive lock function: The train cannot be driven before the load is lifted Lowering only possible with activated handbrake Slow speed in curves until the last axle of the train is back in straight direction Lifting device Load carrier module lifting height 0 -80 mm Form-fitted trolley locking Quiet, electrically powered recirculating ball screw spindles for lifting have integrated shock absorption Module / load carrier coupling Unique train without drawbars but articulated steering system No fit tolerances between module load-carrier connections Silent operating train Safety The innovative Factory Train Compact (FTC) brings a new dimen- sion to efficient and safe material flows for production plants. The Lowering only possible with activated handbrake 3-point construction ensures that all wheels of the train remain in Different load carrier modules available: C-frame, E-frame constant contact to the ground also on uneven surface applications. with fixed or adjustable forks, Bridge-frame, Platform-frame, Raising goods on trolleys with the load carriers above the floor crea- tes a load protecting, low-noise, low-wear and safe load handling Requires adaptation of the tractor (electrical connector, process. An integral drive-lock prevents the tractor moving with lowered load carriers. control console) Performance The modular train principle with its interchangeable carriers is an deliveries. This, combined with the upright standing position for opening efficient and cost-effective solution for a rapid external and internal and closing the comfort-class weather protection, offers the best possib- load transfer. It allows for simultaneous transport of various goods on trolleys. The fully electrical steering is monitored permanently and gives a best in class directional driving stability. The shock absorbing elements combined with the optional available weather The FTC load carrier modules are designed for consistent reliability in protection secure the goods from environmental impact. In case of demanding outdoor and indoor applications. The rugged construction of route/requirement changes, load carriers can be swapped conveni- the low-maintenance modules, the backlash-free connections and the ently or combined differently to enhance the handling capacity and sturdy construction of the load carrier modules guarantee safe and stable to keep the performance level high. The train delivers a comfortable and smooth driving and the quiet Economy and durability of the FT Compact load carrier modules result in operating electrical spindle-lifting can be pre-lowered from the easy diagnosis and preventive maintenance. The CAN bus system enab- tractor or operated directly from the load carrier module. Load les all unit data to be read out for inspection when service is due or for carriers for two or three trolleys keep the train and the walking the change of parameters. Easy accessibility of all components employed distances short and allow for a comfortable follow up on internal plays an additional part in keeping train uptime high. Operation Time-saving pre-lifting and pre– lowering of the load carriers operated from the control console at the tow tractor For on-site-control the lift can be operated directly at the module Console provides visual feedback of lift-units positions CAN bus control system avoids driving with lowered load carriers Linde Material Handling GmbH, Postfach 10 0136, 63701 Aschaffenburg, Germany Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.de, info@linde-mh.de Linde red/anthracite paintwork Slow speed in curves until the last axle of the train is bac

Open the catalog to page 1

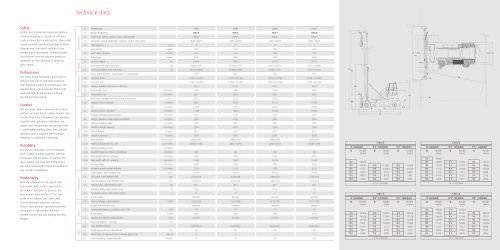

Additional details Front module Weight of train (without tractor)10 with 2 load carrier modules (kg) 830 900 1 100 1 1 70 with 5 load carrier modules 1760 1 830 2330 2400 Load-time diagram for SE-wheels C-frame / E-frame Bridge Frame Options Weather protection V V V V weighing system V V V V Graphical display, digital V V V V Lighting in accordance with regulations V V V V 9 Values analog to FT08 C / FT10 C / FT16 C / FT20 C 2) Values analog to track widths front (see 3.6) 3) Optional outdoor package available...

Open the catalog to page 2All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

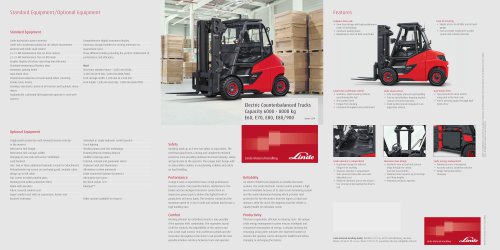

E60 – E80

2 Pages

-

Linde electric forklift

40 Pages

-

P250

24 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

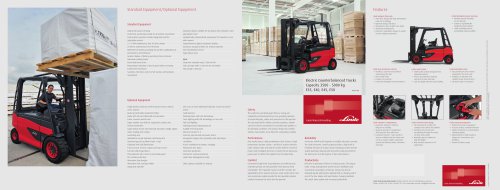

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages