Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

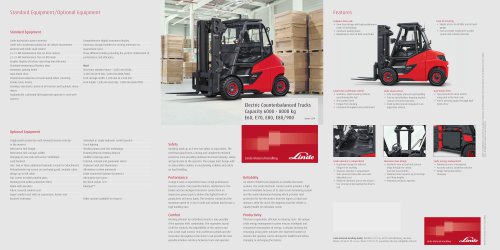

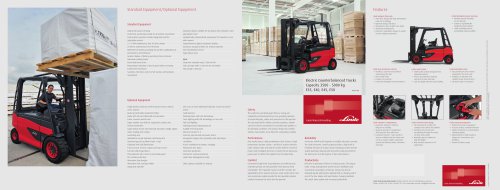

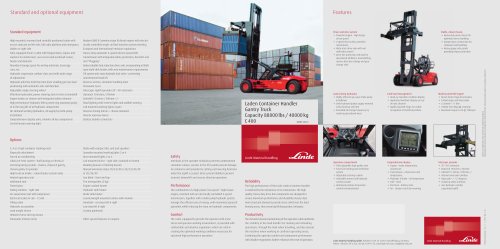

Standard equipment/Optional equipment Standard equipment Operational overhead guard Hydraulic-suspension comfort-class seat with wide range Lockable, underseat storage box Document storage bin - left side of seat Single drive pedal in combination with direction selector Linde load control for low-effort precision control of all mast functions Fixed angle steering wheel Demand-controlled hydrostatic power steering Turbo charged diesel engine Powershift transmission Forward/reverse inhibitor Automatic electronic gearshifting Heavy duty wide track double reduction drive axle Wet disc brake system Brake system accumulator Load sensing hydraulic system with piston type pumps Engine air intake with integral safety element High performance hydraulic filters preserving maximum purity of oil for long life of all hydraulic components Electrically operated tilting loadguard for service access Back-up, manual hydraulic pump for tilting loadguard Single control lever- Lift/tilt operation, variable piston type Single lever control - Fork position operation, gated type Glare-free IQAN display, including all monitoring, warning, control and information functions. Abundant storage space for writing materials, beverage cans, etc. Pneumatic tyres Standard mast, lift height h3 = 4000 mm Fork carriage, width b3 = 2950 mm 18t-25t, 3040 mm 28t-32t Pin type mounted forks Fork carrier to suit standard pin type or hook-on forks Internal rear view mirror Chassis mounted, rear view mirrors Audible warning reverse alarm Truck lighting, Headlights, rear lights, turn indicators, reverse warning lights Rotating warning beacon Standard Linde paint scheme Optional equipment Standard masts, 4000 mm to 10000 mm lift height Single and double auxiliary hydraulics for all mast types Alternative fork lengths Hook-on type forks Flat-face carrier Alternative carriage widths, 3500 mm, 4000 mm, 4500 mm Overhead guard add-ons, front screen, top window, rear window Fully eguipped mid-mounted cabin with hinged doors, front, top and rear screen wipers and washers, heaters and de-misters Adjustable steering column Blinds - roof and front screen Climate control with integral pollen filter High level air intake for heating system Radio-CD player Seat incorporating air suspension with compressor Individual levers - lift and tilt Individual levers - Forkspread and sideshift Gated lever-additional hydraulic service Fire extinguisher, powder 3 kg Central lubrication system Custom paintwork Other options available on reguest counterbalanced truck Load sensing hydraulics -> Highly efficient variable displacement -> Metered oil for function selected -> Lower oil wear giving extended life in Operator's compartment -> Centralised, forward positioned for optimised all-round visibility -> Impact tested loadguard structure -> Maximised glass area with front, top Effortless and smooth load control and manoeuvrability in close surroundings is achieved through the forward positio- ning of the cabin to allow maximum through-mast visibility to the fork tip and load. The visibility from the operator position is optimised by the utilisation of generous glass panels to the front, top, rear and sides. The perfectly balanced load-sensing hydraulic system, in-tune with the optimised performance of the power unit and drive system ensure that the machine is both powerful and smooth in operation during all speeds and modes of The operator's cabin mounted to the chassis through high density rubber mounts, ensures drive and power train vibration, together with operational vibrations are suppressed to provide the operator with a comfortable working environment. The operator's seat is provided with integrated gas spring damping for additional cushioning. Stable, robust chassis -> Heavy duty main chassis for optimi- -> Dual longitudinal chassis sections with lateral stress bracing provided by the drive axle and counterweight, provide high strength to weight ratio Linde Material Handling The proven reputation of variable displacement hydraulic systems, together with the high endurance power and drive systems combine to provide long service in arduous applications; the mast and lifting device have been thoroughly tested for endurance and security in operation to ensure long operational life. The exact matching of the load-sensing hydraulic system with the power drive system, in harmony with the optimi- sed positioning of the operator controls and instrumentati- on within the spacious cabin, provide a perfectly balanced working environment for the operator, thus facilitating stress-free operational conditions for extended working Operator's controls Linde control levers Twin pedal foot brake Column mounted handbrake Centralised Igan display Power and Drive system -> Powerful modern diesel engine giving high performance combined with low fuel consumption and exhaust emissions -> Torgue converter coupled power-shift transmission with automatic electronic controlled gear shift -> Wide-track drive axle with wet disk brake system -> Drive-line protection with built-in opera- tional inhibitors: downshifting, reverse direction change, gear change ratio Free-sight mast -> Unigue mast profile developed to facilitate both compact and also optional container handling -> Optimised forward visibility by pla- cing all operational parts behind or to the outside of the mast profile -> Universal terminal-west type car- riage system with interchangeable carriers and forks, for multi-functo- Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany Linde Material Handling

Open the catalog to page 1

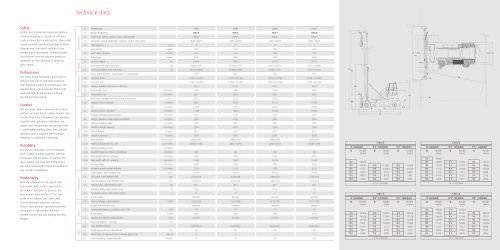

Technical data Model designation Power unit: battery, diesel, LP gas, mains power Operation: manual, pedestrian, stand-on, seated, order picker Rider seated Rider seated Rider seated Rider seated Rider seated Load capacity Load centre Axle centre to fork face Service weight Axle load with load, front/rear Axle load without load, front/rear Rider seated Rider seated Tyres, front/rear. SE = (superelastic), P = (pneumatic) Tyre size, front Tyre size, rear Wheels, number, front/rear (x = driven) Track width, front Track width, rear Mast/fork carriage/truck tilt, forward/backward Height of mast...

Open the catalog to page 2All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

E60 – E80

2 Pages

-

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages