Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

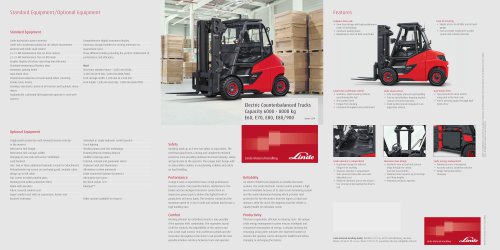

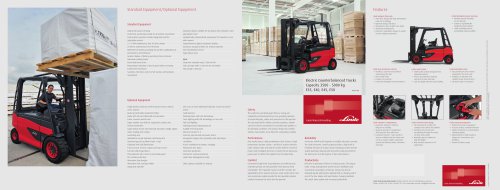

Standard Equipment Original Linde hydrostatic drive 3 Sensitive, smooth, and precise driving 3 Variable displacement pump for best energy consumption 3 No clutch, no differential, and no drum brakes thanks to hydrostatic direct drive 3 Robust drive even in extreme environments Linde twin drive pedals to control forward/reverse travel and LPG truck fitted with accurate ultrasonic fuel level indicator Original Linde Load Control integrated in armrest LPG volumetric fuel tank version with fuel level indicator at Hydraulic suspended comfort-class seat with extensive range Linde ProtectorFrame 3 Enclosed, robot-welded chassis for maximum durability and protection of components 3 A hinged engine cover and removable service panels give wide, easy access for maintenance 3 Hand grip on A-pillar for safe on/off access Superelastic tyres Hydrostatic steering, kickback free High safety and stability ensured by Linde ProtectorFrame New STANDARD features for the Evo models: Anti-glare display with fuel gauge, clock, hour meter and Variable displacement pump for best energy consumption service information Integrated diesel particulate filter for EU models with 44 kW Control lights on display for engine oil pressure, engine over- New seat/armrest generation for outstanding ergonomics heating, parking brake, audible warning signal for engine and hydraulic oil temperature, blocked intake filter and low fuel LEPS (Linde-Engine-Protection-System) as monitoring of the most important truck parameter Plenty of storage space for writing utensils, beverage cans... Curve Assist for automatic speed adaption Air intake filter with integrated cyclone separator Intelligent drive dynamic modi now integrate lift hydraulic High-performance hydraulic filter concept, guarantees maxi- New development timing belt protection mum oil purity and extends life of all hydraulic components Enhanced steering axle LPG truck fitted with a two-way catalytic converter Handhold for safe access at A-pillar The mounting of the gas bottle is ergonomically designed for Diesel, LPG and CNG Forklift Trucks Capacity 2500 - 3500 kg H25/600 , H30/500 , 393_02 H35/500 easy changing Linde twin drive pedals 3 Fast and smooth travel directionchanges without constantly moving feet from one pedal to the other 3 Short pedal travel 3 No strain on ankles or legs 3 Operator maintains high efficiency levels Linde Load Control 3 Mini levers for all mast funtions mounted on an adjustable armrest 3 Precise and effortless fingertip control of all mast functions for safe, efficient load handling 3 Engine rpm is automatically synchronised to precisely match hydraulic demands High-economy engine technology 3 Modern, advanced technology Diesel, LPG and CNG engines matched to Linde‘s demanding requirements 3 High torque for impressive and flexible performance 3 Extremely fuel efficient 3 Exhaust emissions significantly below the current European limits Linde operator‘s compartment 3 Advanced functional design for optimum operator comfort and efficiency 3 Superb working environment with spacious leg and headroom 3 Excellent visibility of load and surrounding environment through the slim-line mast sections 3 Resilient mounting of mast and drive axle absorbs road shocks and vibrations 3 Quiet, stress-free working Variable displacement pump 3 For mast functions and additional hydraulic circuits 3 Electrically controlled by Linde Load Control levers 3 The Linde pump only provides the required oil volume 3 Less fuel consumption 3 Less noise 3 Extended oil change intervals Linde clear-view mast 3 Superb visibility through the slim profile mast sections 3 Full load capacity available up to maximum lift height 3 Excellent residual capacities 3 Maintenance-free resilient rubber mounting of mast/drive axle and tilt jacks 3 Electronic control of tilt angle 3 Electronic cushioning of end travel for forward/back tilt Optional Equipment Alternative fork lengths Overhead guard can be upgrated to full cabine with roof, front Tilt cylinder- and roof protection Linde ProtectorFrame: The protective overhead guard and and rear screens and doors (also available with tinted glass) Truck lighting, working lamps its supporting frame together form a strong protective zone Wiper-washers for front, rear and roof screens Audible reversing alarm, flasher and strobe beacons providing optimum safety and protection for the operator. Further seats with additional comfort and adjustments Top-mounted tilt cylinders provide seamless and smooth Cab heater with integrated pollen filter Linde original Blue Spot control of the tilt movements for excellent load stability in Camera and colour monitor all operating conditions. This unique design also enables Radio with CD-player and speakers Road traffic specifications slimmer mast profiles to be fitted for outstanding visibility. Sun screens, clipboard, interior lighting, height adjustable steering column Standard masts from 3,150 mm to 6,550 mm lift Water trap with audible warning Low consumption and exhaust level and nevertheless this Proven in tough applications. Decoupling of mast and drive Duplex masts (full free lift) from 3,165 mm to 4,765 mm lift Volumetric tank (LPG) with capacities of 45 l or 55 l truck range continues to impress with its excellent perfor- axle with chassis and cabine results in reduced shock and Triplex masts (full free lift) from 4,705 mm to 6,455 mm lift mance. Advanced engine and drive technology combined vibration. The enclosed robot-welded chassis is designed for Integrated sideshift Unregulated catalyst (Diesel) with the original Linde Load Control system enables the ope- maximum strength and durability. The resilient, maintenance- Integrated fork positioner rator to use the trucks vast potential to maximise productivi- free mountings of the axles and tilt jacks cut downtime and Load backrest Linde Forklift Data Management ty. Precise fingertip control of all mast functions. operating costs. One or two auxiliary hydraulic circuits for all mast types Custom paintwork Step in relaxed, leave again relaxed. Linde brings to this 50 years of permanent optimisation of the original Linde forklift a generously sized automobile-class workspace. hydraulic system leads to effective and cost-efficient work: The Picture top: Beverage application A perfect interface between operator and truck has been original Linde hydrostatic transmission requires no differential, Picture middle: Beverage version achieved with the Linde ergonomic design concept. The no drum brake, no gearshift and no clutch. As a result, uptime Picture bottom: CNG version spacious cab, comfort-class seat with adjustable armrest is optimised, productivity is increased and maintenance costs and intuitive controls allow fast and stress-free working. Other options available on request Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.com, info@linde-mh.com Single drive pedal with direction selector on armrest Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual constructions. All dimensions subject to usual tolerances. Standard Equipment/Optional Equipment

Open the catalog to page 1All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

E60 – E80

2 Pages

-

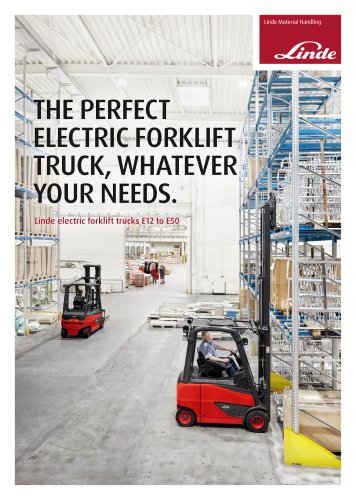

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages