Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

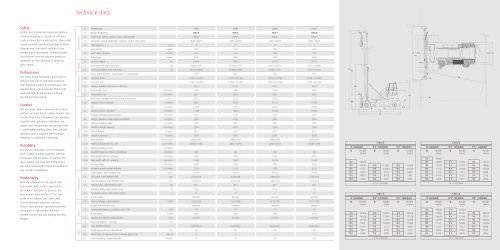

Standard Equipment/Optional Equipment Standard Equipment 1) 2 High 9'6" on sidelift beam 2) 3 High 9'6" on sidelift beam 3) 4 High 9'6" on sidelift beam Operational overhead guard height 3027mm Hydraulic-suspension comfort-class seat with wide range of Lockable, underseat storage box Document storage bin - left side of seat Linde twin drive pedals to control truck travel Linde Load Control for low-effort precision control of all mast adjustable steering column Demand-controlled hydrostatic power steering, fuel-economi- zing, easy and precise response Engine intake air cleaner with integral safety element High-performance hydraulic filter preserving maximum purity of oil for long life of all hydraulic components Manual hydraulic pump for tilting loadguard Single control lever - Lift/tilt operation, variable position type Single control lever - Fork position operation, gated type Central display including fuel gauge, clock, hour meter and servicing information for all important truck functions Optional Equipment Single drive pedal in combination with direction selector in Standard masts, 2430mm to 9500 mm lift height (model speci- fic, refer to mast table) Duplex masts (full free lift), 2580mm to 7000 mm lift height (model specific) Triple mast (Full free lift) - 4000mm to 10000mm lift height (model specific) Integral fork positioner Single and double auxiliary hydraulics for all mast types Alternative fork lengths Fork carrier to suit standard pin-type or hook-on forks Pin-type mounted forks Hook-on type forks Flat face carrier Alternative carriage widths - 3000 mm, 3500 mm, 4000 mm, Overhead guard add-ons - Front screen, top window, rear Cabin with front, top and rear washer/wipers with heater and right hand sliding window Deluxe cabin with climate control, heated seat, adjustable steering column, roof and front screen blinds, front, top and rear washer/wipers and right hand sliding window Abundant storage space for writing materials, beverage Pneumatic tyres Standard mast, lift height h3 = 4000mm Fork carriage, width b3 = 2545mm Manual fork carriage system Roller mounted forks Internal rear-view mirror Audible warning reverse alarm Chassis mounted hour counter Standard Linde paint scheme Dustbowl air intake filter Seat incorporating air suspension with compressor Individual levers - lift and tilt Individual levers - Forkspread and sideshift Gated lever - additional hydraulic service Individual levers - additional hydraulic service Radio with compact disc player and speakers Truck lights, work lamps Highway specifications Integral particulate filter with loading indicator in display for diesel-engine version Reversing warning signal, beacon lamps Blinds - roof and front screen Accumulator for hydraulic service On-board battery charger High level air intake for heating system Electrically operated tilting loadguard for service access Rear View Camera system and screen Custom paintwork Forklift Truck Perfect load control and manoeuvrability in close surroun- dings is assured at all times. Linde achieves this by placing the cabin in a forward, optimised position to allow maximum through-mast visibility to the fork tip & load. The visibility around the machine from the operator position is optimised by the utilisation of generous glass panels to the top, rear & sides. The curved widescreen provides continued uninter- rupted visibility around to the side screens. The finely tuned hydrostatic drive system ensures precision in operation balanced with optimised speed of performance. The stepless drive system ensures that acceleration through to top speed is without mechanical intervention: providing smooth operation. The precision in operation of the hydro- static system ensures that the operator is able to engage the load with precision, therefore limiting impact shock. The operators cabin is mounted to a tilting frame on high density rubber mounts, this ensures that drive, power train & operational vibrations are suppressed to provide the opera- tor with a comfortable working place. The operator's seat is provided with hydraulic damping for additional cushioning. The proven reputation of the hydrostatic drive systems coupled together with the power unit provide peace of mind for the drive system; the mast and lifting device has been thoroughly tested for endurance and security in operation, to ensure a long operational life. With the utilisation of the world-class hydrostatic drive system, speed and precision in operation is assured, the operational characteristics of the twin pedal drive system, and Linde Load Control hydraulic operators controls, ensure that minimal ope- rator movement is reguired to operate the machine, thereby saving time and limiting operator fatigue. Power and Drive system -> Linde hydrostatic drive system providing stepless, precise operator control -> Low speed, high torgue diesel engine matched to hydrostatic drive and hydraulic service pump reguirements Operators compartment Forward positioned for optimised all- round visibility Impact tested loadguard structure Integrated overhead guard Linde twin accelerator pedals -> Instant direction change -> Precise travel movement -> Reduces operator foot movement Operator's controls -> Linde Load Control levers -> Twin pedal drive system -> Console mounted handbrake -> Centre emergency brake pedal -> Centralised glarefree multifunction IQAN display Linde Load Control -> Standard operator controls providing effortless operation -> Twin-pedal drive system -> Linde Load Control levers -> Reduced operator stress Linde Truck Control -> Reliable electronic controller -> High dependability resulting from redundant monitoring systems -> Automatic control of engine speed as -> Casing totally enclosed for protection from dust and dirt Modern, powerful engine -> Diesel motor, stage Ilia emissions Linde clear-view mast -> Unigue mast profile developed to faci- litate both compact fork handling and also optional empty container handling -> Optimised forward visibility by placing all operational parts behind or to the outside of the mast profile -> Universal ,terminal west' type carriage system with integrated roller mounted Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany Phone +49.6021.99-0, Fax +49.6021.99-1570, www.linde-mh.com, info@linde-mh.com

Open the catalog to page 1All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

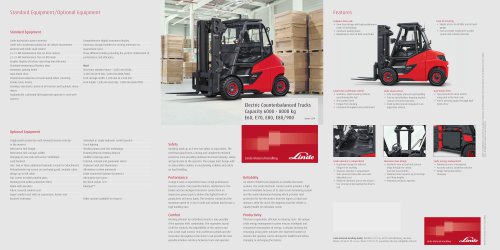

E60 – E80

2 Pages

-

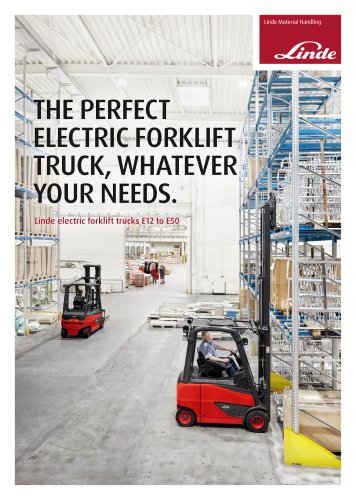

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

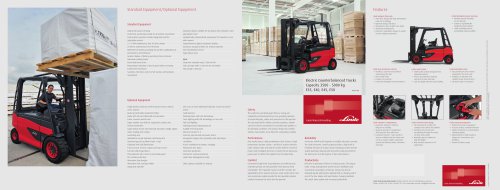

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages