Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

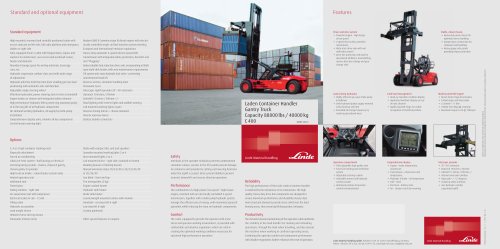

Standard Equipment Standard truck height or comfort version (+ 80 mm) Hydraulically cushioned full suspension PVC operator‘s seat Central lever (joystick control) integrated into the with armrest adjustable armrest Comprehensive digital instrument display 2 x 9 kW maintenance free AC drive motors Generous storage facilities for writing materials 22 kW AC maintenance free lift motor Different ECO modes providing the perfect combination of appropriate mast (not high comfort version) Linde twin accelerator pedals for all vehicle movements E25R/E25RL Standard chassis suitable for working in ISO containers with Hydrostatic power steering Linde hydrostatic power steering 3 Minimal physical demands on the operator 3 Compact ergonomically designed steering wheel 3 Linde combi steer axle for outstanding manoeuvrability Linde compact drive axle 3 Twin drive design with high performance Linde AC technology 3 Optimum energy efficiency 3 Maintenance-free oil-bath vane brake 3 Automatic parking brake 3 Latest DCB-power moduls are mounted on the drive axle - highest efficiency due to very compact conductors to the motors Superelastic tyres performance and efficiency Graphic display of remaining battery operating time in minutes Automatic parking brake Fork carriage width: Linde dual motor drive (Curve Assist) Seamless electronic control of all traction and hydraulic Clearview standard mast Linde patented combi axle in all models up to 3.5t Proportional reduction of travel speed when cornering Linde twin accelerator control 3 Seamless, rapid reversing without repositioning the feet 3 Short pedal travel 3 Fatigue-free working 3 Increased throughput and performance Linde Load Control 3 Small tactile joystick integrated into the adjustable armrest 3 Precise and effortless fingertip joystick control of all mast functions 3 Safe and highly efficient load handling Linde Dual Motor Drive 3 Two powerful AC drive motors integrated in the front axle 3 Infinitely acceleration and variable torque characteristics 3 Extremely quiet in operation Linde operator’s compartment 3 Ergonomically designed for efficient, fatigue-free working 3 Spacious operator’s compartment with generous floor plate area 3 Cushioned comfort – mast and drive axle are isolated from the chassis and cab by a unique resilient suspension system that absorbs shock loadings World‘s best visibility 3 Removel of the A-pillars for an excellent view to load and environment 3 Large and open steel strutted roof enables superb visibility to the top 3 Optional the world‘s largest armored glass forklift truck roof for an unobstructed view 3 Reduced risk of accidents due to better all-around visibility 3 Integrated access grip for safe and easy entry Linde energy management 3 Optimised energy consumption 3 Accurate battery condition indicator 3 Simple horizontal or vertical battery changing options 3 Optional built-in high frequency charger for convenience and flexibility 3 Record of battery usage and condition Optional Equipment Top screen: 20mm armored safety glass & wipe/wash system One or two additional hydraulic circuits for attachments Windshield: 10mm frameless armored safety glass Working lamps and truck lights with LED technology The world’s first Roadster for counterbalanced trucks is set- Rear screen Flashing beacon/rotating beacon/BlueSpot™ ting the new standard in terms of visibility and safety. This Overhead guard sun blind Audible reversing alarm unique design allows for a superb panorama view due to Single pedal accelerator with forward/reverse selector removed A-pillars. A steel strutted roof or an optional armo- Fabric covered comfort seat External, internal and panoramic mirror red glass roof, which is connected at the mast and the tilt Super-comfort seat with air suspension, heater and Integrated charger unit, optionally with electrolyte cylinder support, forms the new protective zone around the backrest extension Swiveling seat Active ventilation for battery charging Individual or single hydraulic control joystick Alternative tyre types Clipboard with LED illumination Alternative custom paintwork One would expect a high performance truck to have a high An electric forklift truck depends on reliable electronic systems. Alternative fork carriage widths Connected solutions like access control for individual driver performance traction system – and that is exactly what the The Linde electronic control system provides a high level of Integrated sideshift authorization, recording and remote transfer of the opera- Linde compact drive axle and lift system delivers. Powerful reliability because of its dual circuit monitoring system and Integrated fork spreader ting hours and active usage analysis of complete truck fleet motors and intelligent electronic control form an impressive sealed aluminium housings which provides total protection for power pack to deliver the highest level of productivity. the electronics from the ingress of dust and moisture. Consistently high levels of performance and efficiency for Effective in operation, efficient in reducing costs: The unique extended periods are only possible if the operator feels Linde energy management system ensures intelligent and comfortable. The ergonomic layout of all the controls, the economical consumption of energy. Energy can also be adjustability of the armrest and seat, Linde Load Control, and obtained quickly utilising the optional built-in charging unit or twin accelerator pedals provide the best possible intuitive one of the four simple and rapid battery changing methods. interface between the truck and the operator. Combined The result: more uptime and increased productivity. The unbea- with the excellent view, the Roadster offers the operator table visibility of the Roadster specially for load and environ- unmatched operating comfort. ment further improves the productivity. Other options available on request Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.com, info@linde-mh.com Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual constructions. All dimensions subject to usual tolerances. Standard Equipment/Optional Equipment

Open the catalog to page 1All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

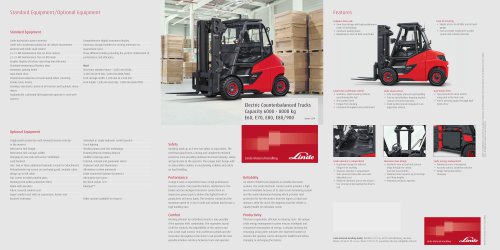

E60 – E80

2 Pages

-

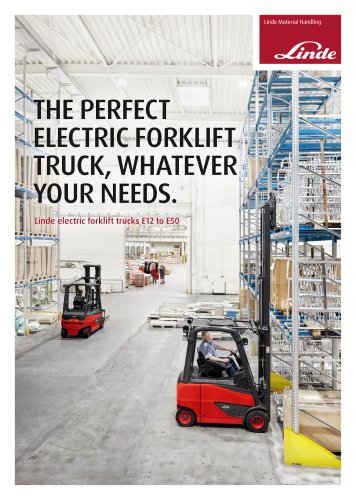

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

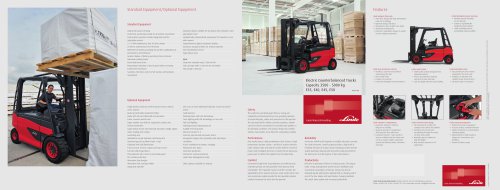

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

E 10

4 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages