Website:

LINDE Heavy Truck Division

Website:

LINDE Heavy Truck Division

Catalog excerpts

Electric Forklift Truck 1000 kg Introduction The new concept counterbalance model E 10, has been designed with a unique stand-on operating position resulting in a compact, highly manoeuvrable truck suited for a main range of applications: such as storage/retrieval, block stacking and rapid load transfer. Available in two versions: standard version and lower container version. Features ● Stand-on operating position angled to the direction of travel providing excellent visibility, complete operator protection and comfort ● Energy saving Digital Control of traction, steering and hydraulics providing quiet, infinitely variable operation ● Two independent braking systems including automatic electric braking (LBC) ● Low overhead guard height enabling operation in ISO containers. Operator’s compartment The operator’s compartment has been designed to ensure optimum operator comfort for high productivity and minimum fatigue. The low access step can be hydraulically raised to achieve the best operating position for individual operators. A padded backrest provides a safe and comfortable operating environment. The operator is diagonally positioned to the direction of travel which minimises head and body movements when changing from forward to reverse. A multi-grip control operated by the left hand incorporates a twist grip for travel speed, direction, automatic and reverse electric braking plus push buttons for lift/ lower and also tilting forks, when fitted. Operation of the ergonomically designed steering wheel is by the right hand. A combined hour meter and battery discharge indicator with lift interlock enables cost effective planning of maintenance intervals and battery charging schedules for optimum performance and safety. Chassis The compact chassis with integrated mast and overhead guard has been designed to achieve maximum strength, rigidity and stability, and is profiled for optimum manoeuvrability and visibility. The motors, sub-components and electronics are all protected within the rugged structure and are accessed via an easily removable steel cover. Access to the battery is via steel top and side covers enabling battery changing from the side using independent lifting equipment. Drive and transmission The drive unit consists of a centrally mounted split field, series wound, 2.2 kW motor driving the spur and bevel transmission unit. Electrical system The truck is fitted with the advanced digital control system which governs traction and hydraulics and gives optimum utilisation of battery energy together with precise, responsive and infinitely variable speed control, smooth acceleration plus automatic and reverse electric braking. The system is self diagnostic and very quiet due to the high frequency actuation of the power transistors. The efficiency of the system allows a high number of work cycles from each battery charge. Steering Hydrostatic power steering requiring only five and a quarter turns lock to lock and a very low steering effort for outstanding manoeuvrability giving maximum operator efficiency with minimum fatigue. Mast and hydraulics The clearview mast, which is bolted to the overhead guard and chassis, has been developed with the aid of the finite element method for optimum strength, rigidity and visibility. A choice of simplex, duplex and triplex, full free lift masts is available. A powerful 3.0 kW motor gives fast lift speeds for high productivity.

Open the catalog to page 1

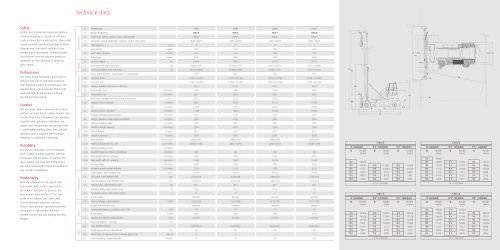

Forklift Truck Designation VDI 3586 Data sheet for materials handling equipment Power unit: battery, diesel, petrol, LP gas, mains power Operation: manual, pedestrian, stand-on, seated, order picker Load capacity Load centre Axle centre to fork face Service weight Axle load with load, front/rear Axle load without load, front/rear Tyres: solid rubber, contoured solid (superelastic), pneumatic, polyurethane Tyre size, front Tyre size, rear Wheels, number front/rear (x = driven) Track width, front Model designation Track width, rear Free lift Height of mast, extended Height of overhead guard...

Open the catalog to page 2

Lifting capacity diagrams: E10 Standard Standard Mast unit Variations Lift height Height mast lowered h1 Height, mast raised h4 Simplex lift mast Duplex lift mast Triplex lift mast Lift height Free lift Free lift Container Mast unit Variations Height mast lowered h1 Height, mast raised h4 Simplex lift mast Duplex lift mast Triplex lift mast (1) With optional tilting fork carriage unit.

Open the catalog to page 3

Subject to modification in the interests of progress. llustrations and technical details not binding for actual construction. All dimensions subject to customary tolerances. Safety ● Two independent braking systems ● Emergency circuit isolator ● Keyswitch ● Fail-to-safe circuitry ● Electric horn ● Electrical and hydraulic overload protection ● Overhead guard. Standard equipment All items as shown under safety ● Multi-grip control of traction and hydraulic functions ● Combined hour meter and battery discharge indicator with lift cut-out ● 2.2 kW drive motor ● Polyurethane tyres ● Linde...

Open the catalog to page 4All LINDE Heavy Truck Division catalogs and brochures

-

TRUCKS FOR VERY NARROW AISLES

32 Pages

-

ORDER PICKER N20 C L

6 Pages

-

H40 – H50 EVO

2 Pages

-

H20 – H35

10 Pages

-

H14 – H20 EVO

10 Pages

-

E10

6 Pages

-

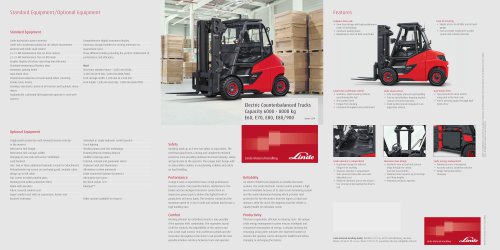

E60 – E80

2 Pages

-

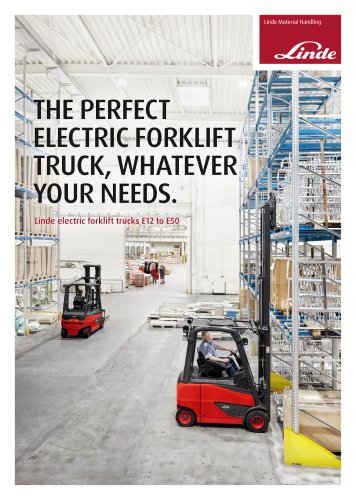

Linde electric forklift

40 Pages

-

P250

24 Pages

-

LT06-LT20

2 Pages

-

H50-H80-EVO

2 Pages

-

H14-H20-EVO

2 Pages

-

H 50-80/1100

2 Pages

-

ht100_180ds

2 Pages

-

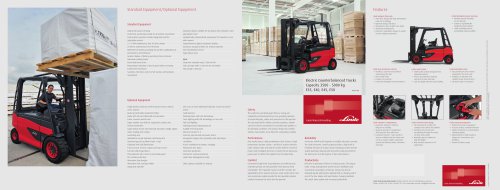

E20-35R

2 Pages

-

E 20-35 HL

8 Pages

-

The power of a good idea.

8 Pages

-

E 60-80/900

2 Pages

-

H 100-180

2 Pages

-

E 35-50/600 HL

2 Pages

-

E 16 P-20 PHL EVO

2 Pages

-

E 12-20 L EVO

2 Pages

-

H 40-50 EVO

2 Pages

-

H 25-35 EVO

2 Pages

-

H 20-25 EVO

2 Pages

-

H 14-20

6 Pages

-

S30-S60

2 Pages

-

C4230 TL - C4535 CH Mk5

2 Pages

-

C400

2 Pages

-

C90/5-C90/8

2 Pages

-

H420-H460

2 Pages

-

H180-320

2 Pages