Catalog excerpts

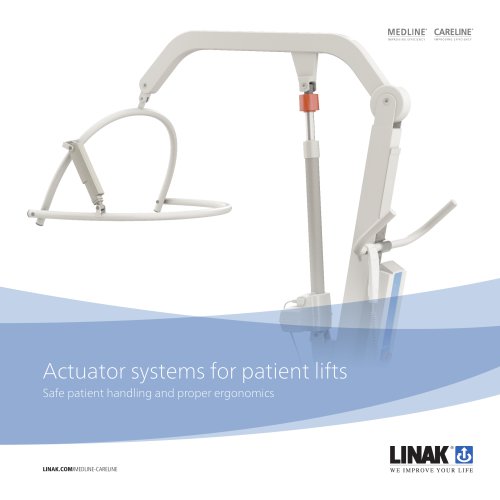

MEDLINE' CARELINE' WE IMPROVE YOUR LIFE

Open the catalog to page 1

Safety is mandatory at LINAK® Different healthcare applications need different safety features. Regardless of what application you are designing, LINAK offers a wide variety of standard and optional safety features. This folder will give you a broader insight into some of our safety features.

Open the catalog to page 2

Rely on your actuator Based on many years of experience in developing electrical actuator solutions LINAK® understands the importance of mixing quality with safety, functionality and design. In order to meet the extremely high standards for healthcare equipment, LINAK actuators contain many different safety features to make sure that you can rely on your actuator at all times.

Open the catalog to page 3

Self-lock: To avoid actuator drifting, and potentially creating dangerous situations, LINAK® actuators come with a self-lock function. The minimum self-lock always equals the max. thrust lifting performance. Mechanical end-stop is an extra safety feature, making the actuator firstfailure-safe. If the electrical end-stop switch should ever fail, the mechanical end-stop effectively stops all movement.

Open the catalog to page 5

Safety nut: A safety nut acts as a precaution against potential failure of the main nut. If the main nut breaks, the safety nut will immediately carry the full load and thereby prevent potentially harmful falling. Spline: LINAK® offers three different types of spline: mechanical, electrical and ratchet spline. All three spline types prevent accidental squeezing of limbs between moving parts in an application and prevent the application from being damaged.

Open the catalog to page 7

Quick release is an important functionality that ensures fast lowering of the application in emergency situations, e.g. if CPR is needed. Manual lowering is a standard safety feature for lifting actuators in hoists and is used in emergency situations if a power cut occurs.

Open the catalog to page 9

LINAK® OpenBus™ - safety included LINAK has a series of intelligent OpenBus™ control boxes. Apart from being able to coordinate multiple actuators to form complex and precise movement patterns, they include several safety-improving features like e.g. Power Request: The LINAK OpenBus™ technology platform includes a unique safety concept consisting of two seperate circuits - data and power request. Both data and power request need to be active to run a function. This reduces the risk of unintended movement to an extremely low level, increasing the safety of the applicat

Open the catalog to page 11

Mains indicator: LINAK® control boxes have a mains indicator. This shows that the application is connected to mains, and cannot be moved safely before unplugging the cables. This reduces the risk of damaging the cables. Brake alarm: The LINAK OpenBus™ control boxes have a buzzer, which can be used as a brake alarm. When connected to mains, the system will activate an alarm if the wheels are not braked. This helps prevent damage to your healthcare application and increases patient safety.

Open the catalog to page 13

Safety right at hand The development of LINAK® hand controls for healthcare equipment are based on research and usability studies to ensure proper functionality, intuitive interfaces and ergonomic design. This all increases the safety related to the use of the hand controls.

Open the catalog to page 14

PU cables are able to retain their shape and are not as vulnerable as traditional PVC cables. This prolongs the cable life and prevents damage to the cable when moving the application. Locking functionality: According to the IEC 60601-2-52 it is required that control functions can be locked. LINAK® hand controls or attendant controls provide the possibility of adjusting and locking the use of specific functions and movements, thus preventing the occurrence of a dangerous position via improper use of the control.

Open the catalog to page 15

General safety features Enhancing safety is often a mix of several initiatives. To make healthcare applications able to be in compliance with the rules in force requires a broad focus. At LINAK® we have a high focus on specific product safety features. However, we also consider overall perspectives of general safety.

Open the catalog to page 17

Flammability Classified: LINAK® products are made of UL94 flammability classified materials – i.e. in compliance with IEC 60601-1 requirements. To minimise the risk of fire hazards, LINAK control boxes are made of UL94 V0 material, an even tougher requirement than stated in IEC 60601-1. Cable locking: LINAK products include cable locks to ensure that cables are connected at all times and the application is ready for electrical movement. The control boxes are constructed with a strong cable lock, protecting cables and plugs against physical stress and strong detergents.

Open the catalog to page 19

Service Data Tool (SDT) makes it possible to read out service data from the OpenBus™ control box by informing about the use of the actuator system. SDT acts as preventive maintenance by disclosing wear and tear long before the system fails. This ensures minimal downtime as maintenance can be scheduled in due time. Efficient maintenance also helps prevent misuse, thus prolonging the equipment life.

Open the catalog to page 21

Water protection: Many healthcare applications must be able to withstand water and detergents when washed. LINAK® products for healthcare are at least IPX4 rated, however, when required, our systems can rate as high as IPX6 Washable DURA™.

Open the catalog to page 23

If you want to know more about safety and LINAK actuator solutions, please contact us or go to our websites. About safety Find your local LINAK office T E RMS O F USE The user is responsible for determining the suitability of LINAK products for a specific application. LINAK takes great care in providing accurate and up-todate information on its products. However, due to continuous development in order to improve its products, LINAK products are subject to frequent modifications and changes without prior notice. Therefore, LINAK cannot guarantee the correct and actual status of said...

Open the catalog to page 24All Linak catalogs and brochures

-

Control Box CO71

13 Pages

-

Foot Switch FS3

8 Pages

-

Actuator LA40

16 Pages

-

DESKLINE®

12 Pages

-

Quality Matters

8 Pages

-

Built-in DB5

4 Pages

-

Built-in DB6

8 Pages

-

Built-in actuator DB14

4 Pages

-

External charger CHJ2

4 Pages

-

Better Solutions - Better Care

28 Pages

-

Bluetooth® Adapter

4 Pages

-

Battery pack BAJ

6 Pages

-

Li-Ion battery disclaimer

2 Pages

-

Focus on Marine

24 Pages

-

TECHLINE Overview

20 Pages

-

LA36

40 Pages

-

LA31

8 Pages

-

LA25

40 Pages

-

LA23

8 Pages

-

LA12

17 Pages

Archived catalogs

-

ACTUATOR LA28 COMPACT

8 Pages

-

ACTUATOR LA28

8 Pages

-

ACTUATOR LA22

4 Pages

-

ACTUATOR LA14

24 Pages

-

Lifting Column DL4

4 Pages

-

Dual Actuator TD1 280 SMPS

4 Pages

-

Lifting Column BL1

4 Pages

-

linear actuator la35 MODBUS

2 Pages

-

linear actuator LA35

8 Pages

-

Linear Actuator LA29

4 Pages

-

Linear Actuator LA23

4 Pages

-

Linear Actuator LA12

8 Pages